DTF printing is revolutionizing the world of textile decoration, and WHAT.EDU.VN is here to provide you with a detailed understanding of this innovative technique. If you’re seeking a cost-effective and versatile printing solution, explore how DTF printing excels in creating vibrant, durable designs on a variety of fabrics. Discover the advantages of direct to film printing and how it compares to other methods like DTG and white toner. Dive in to learn all about direct transfer film, textile printing, and fabric decoration.

1. Understanding DTF Printing

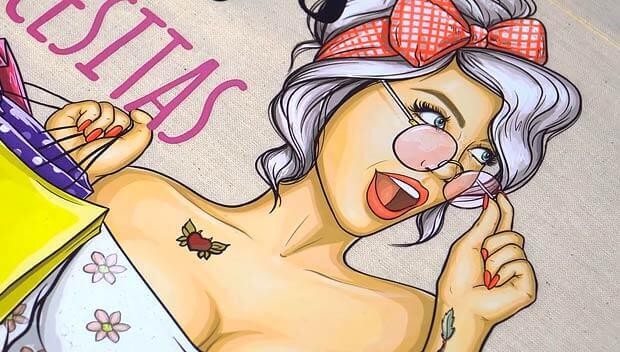

DTF, or Direct To Film, printing is a method that involves printing your designs onto a special film and then transferring that print onto garments like T-shirts, regardless of the fabric or color. This technique works exceptionally well on cotton, polyester, and blended materials. The ability to use white ink is a key component of DTF, making it suitable for dark-colored fabrics where vibrant, opaque prints are essential.

While it may seem like another variation of transfer printing, DTF utilizes a modified desktop inkjet printer equipped with specialized textile inks designed specifically for DTF applications. At WHAT.EDU.VN, we aim to clarify and simplify complex topics, ensuring everyone from students to professionals can grasp the core concepts.

2. The DTF Printing Process: A Step-by-Step Guide

One of the standout features of DTF printing is its simplicity, largely due to the simultaneous printing of the white ink layer with the colored inks. This efficient approach sets it apart from other methods like white toner printing, which can be more complex.

Here’s a breakdown of the DTF printing process:

- Design Preparation: Ensure your design is in a compatible format such as EPS, PS, PDF, BMP, TIF, JPG, PNG, or PSD.

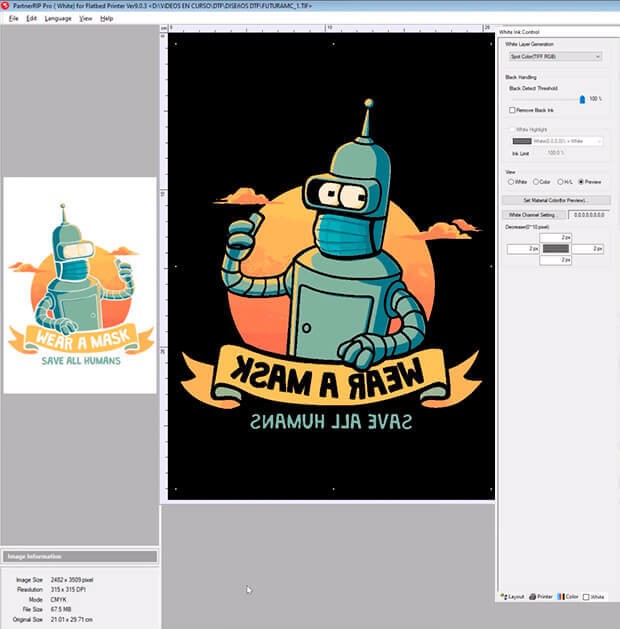

- Printing on Film: Load the DTF film into the modified inkjet printer. The printer will lay down the colored inks (CMYK) followed by a layer of white ink.

- Applying DTF Powder: While the ink is still wet, evenly apply DTF powder to the printed film. This powder acts as an adhesive, bonding the ink to the fabric during heat pressing.

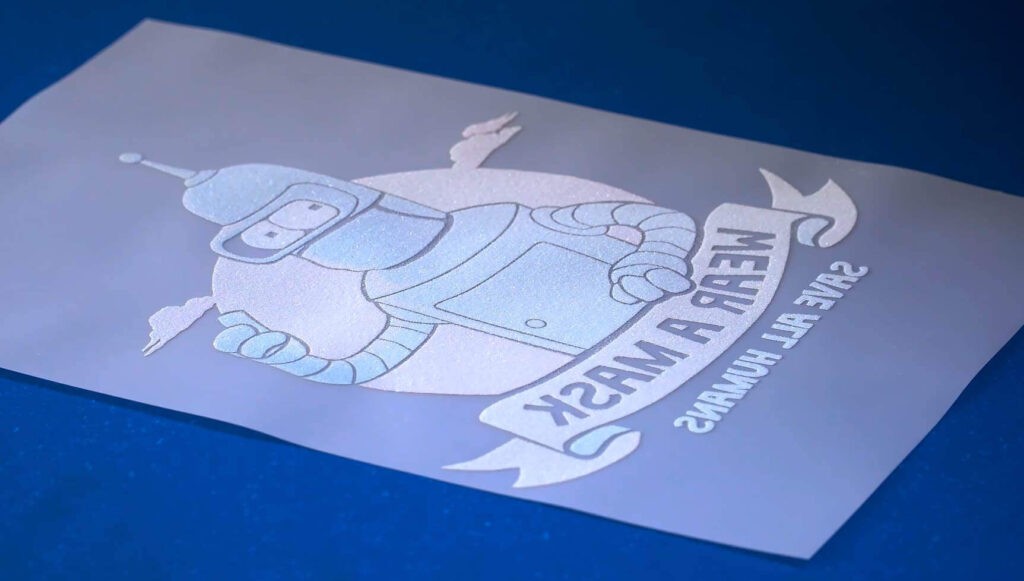

- Curing the Powder: Remove any excess powder and cure the film using a heat press or a curing oven. This step melts the powder, creating a sticky surface.

- Heat Transfer: Place the film onto the garment and use a heat press to transfer the design. The heat activates the adhesive, bonding the ink to the fabric fibers.

- Peeling the Film: After heat pressing, allow the film to cool slightly before peeling it away, leaving the design permanently adhered to the garment.

3. Essential Equipment for DTF Transfers

If you’re considering incorporating DTF printing into your business, understanding the necessary equipment is crucial. DTF printing is quickly becoming one of the most popular alternatives for textile printing.

3.1. Key Components

- Modified Inkjet Printer: A standard inkjet printer adapted for DTF printing, typically with six ink channels to accommodate CMYK and white inks.

- Special DTF Inks: Elastic inkjet inks that prevent cracking when the printed garment is stretched.

- DTF Film: The substrate onto which the design is printed.

- DTF Powder: An adhesive that binds the inks to the fabric fibers.

- RIP Software: Required to manage the printing process, ensuring correct layering of CMYK and white inks.

- Heat Press: Used to transfer the design from the film to the garment. A vertically descending upper platen is recommended for even curing.

3.2. Cost Considerations

One of the major advantages of DTF printing is its affordability. A complete starter kit, including the printer and necessary consumables, can often be acquired for under €1500 (approximately £1248), making it an accessible option for small businesses.

Many suppliers offer low-cost DTF starter kits that include an A3 printer, RIP software, and all essential consumables. If you already own a heat press or curing oven, the initial investment is even lower. A heat press with a vertically descending upper platen, like the Brildor XH-B2N, is highly recommended for optimal results.

4. DTF vs. DTG: Key Differences

Both DTF and DTG (Direct To Garment) printing utilize inkjet technology with white ink, but they differ significantly in several key areas. Understanding these differences can help you determine which method is best suited for your specific needs.

4.1. Investment

DTF printing requires a significantly lower initial investment compared to DTG printing. A DTF kit can cost as little as one-tenth of the price of a DTG printer.

4.2. Production Time

DTF printing involves printing on film, applying powder, curing, and then heat pressing onto the fabric. DTG printing, on the other hand, prints directly onto the garment, which can significantly reduce production time.

4.3. Print Quality and Finish

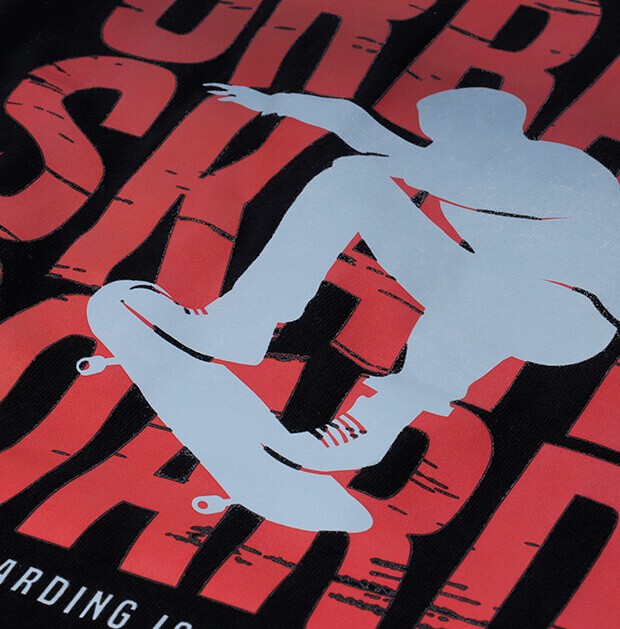

DTF prints have a slightly plasticized feel, similar to heat transfer vinyl (HTV) or screen print transfers. DTF inks are elastic, preventing cracking when the garment is stretched. DTG printing results in the ink being fully absorbed into the fabric, providing a softer feel and better integration.

4.4. White Ink Intensity

DTG printing generally produces a purer and more intense white compared to DTF printing.

4.5. Consumable Costs

Both DTF and DTG have relatively low production costs. While DTF may appear more expensive due to the additional supplies needed, the final cost per T-shirt is often slightly lower than with DTG printing.

5. DTF vs. White Toner: A Detailed Comparison

DTF printing shares similarities with white toner printing in that both methods involve printing a design before transferring it to a garment. The final result also has a similar feel.

5.1. Investment

A DTF kit is more affordable than a laser printer, typically costing about half the price of a Uninet or OKI laser printer.

5.2. Printing Process

DTF printing is simpler than white toner printing because the white layer is printed simultaneously with the color layer, unlike some lower-cost white toner systems.

5.3. Weeding

White toner printing often requires pressing the printed paper A onto paper B to add adhesive and then weeding the design. This step can be delicate and prone to errors. DTF printing eliminates this step, saving time and reducing potential losses.

5.4. Print Quality and Finish

The finish feels similar for both techniques, but DTF inks are specifically designed for textiles, offering greater elasticity and durability.

5.5. White Ink Intensity

White toner printing typically provides a more intense white color compared to DTF printing.

5.6. Consumable Costs

White toner printing has higher consumable costs due to the toner and specialized transfer papers required. DTF printing can reduce production costs by up to 50% compared to white toner.

5.7. Versatility

DTF printing is primarily used for textiles, while white toner laser printing can be used on a wider range of materials, including rigid objects.

6. DTF Printing: Advantages and Disadvantages

To give you a clear overview, here’s a recap of the pros and cons of DTF printing:

6.1. Advantages

- Low Investment: Affordable setup costs make it accessible for small businesses.

- Versatile Fabric Compatibility: Works on T-shirts of any color or fabric type.

- Elastic Prints: Resists cracking when the fabric is stretched.

- High Durability: Excellent wash and wear resistance.

6.2. Disadvantages

- Print Feel: The print can have a slightly plasticized feel, similar to screen printing or HTV.

- Process Complexity: More complex than some other methods like sublimation or DTG.

7. Is DTF Printing Right for You?

DTF printing is ideal for businesses looking to offer personalized T-shirts or other textile products, such as cushion covers, masks, bags, and sweatshirts, on cotton, polyester, or blended fabrics of any color. Its low initial investment makes it a compelling option for startups and small businesses.

8. Frequently Asked Questions (FAQ) About DTF Printing

To address common questions and provide further clarity, here’s a detailed FAQ section covering various aspects of DTF printing:

| Question | Answer |

|---|---|

| What types of fabrics can DTF printing be used on? | DTF printing is versatile and can be used on a wide range of fabrics, including cotton, polyester, blends, and even some synthetic materials. This makes it suitable for various applications, from apparel to home décor items. |

| What is the ideal temperature for heat pressing DTF? | The ideal temperature for heat pressing DTF transfers typically ranges from 150°C to 160°C (302°F to 320°F). However, it’s crucial to check the specific recommendations provided by your DTF film and powder supplier, as variations may occur. Proper temperature ensures the adhesive melts correctly and bonds the design to the fabric effectively. |

| How durable are DTF prints? | DTF prints are highly durable and offer excellent wash and wear resistance. The elasticity of DTF inks prevents cracking and peeling, ensuring the designs remain vibrant and intact even after numerous washes. |

| What file formats are compatible with DTF printing? | DTF printing supports a variety of file formats, including EPS, PS, PDF, BMP, TIF, JPG, PNG, and PSD. It’s recommended to use high-resolution files to ensure the best print quality. |

| Can DTF printing be used on dark-colored garments? | Yes, DTF printing is particularly effective on dark-colored garments. The use of white ink as a base layer allows for vibrant and opaque designs to be printed on dark fabrics, ensuring the colors stand out. |

| How does DTF printing compare to sublimation? | DTF printing is more versatile than sublimation, as it can be used on a wider range of fabrics, including cotton and dark-colored materials. Sublimation is limited to polyester fabrics and light colors. DTF also offers better durability and wash resistance compared to sublimation. |

| What is the purpose of DTF powder? | DTF powder acts as an adhesive, bonding the inks to the fabric fibers during the heat pressing process. It is applied to the wet ink on the printed film before curing. The powder melts and creates a sticky surface that adheres to the fabric when heat is applied. |

| Do I need special software for DTF printing? | Yes, RIP (Raster Image Processor) software is essential for DTF printing. This software manages the printing process, ensuring correct layering of CMYK and white inks. It also optimizes color accuracy and print quality. |

| What maintenance is required for DTF printers? | Regular maintenance is crucial for DTF printers to ensure optimal performance. This includes cleaning the print heads, replacing ink cartridges, and maintaining the heat press. Proper maintenance prevents clogs and ensures consistent print quality. |

| How long does a DTF print last? | With proper care, DTF prints can last for an extended period. The high wash and wear resistance of DTF inks ensures the designs remain vibrant and intact after numerous washes. It’s recommended to wash garments inside out in cold water and avoid using harsh detergents or bleach to prolong the life of the print. |

9. Still Have Questions? Ask WHAT.EDU.VN!

If you have any further questions or need clarification on any aspect of DTF printing, don’t hesitate to reach out to WHAT.EDU.VN. We’re here to help you navigate the world of textile printing and find the best solutions for your needs.

Feel free to leave a comment or contact our Customer Service department at 888 Question City Plaza, Seattle, WA 98101, United States, or via WhatsApp at +1 (206) 555-7890. Visit our website at WHAT.EDU.VN for more information and resources.

At WHAT.EDU.VN, we understand the challenges of finding quick and reliable answers. That’s why we offer a platform where you can ask any question and receive prompt, accurate responses from knowledgeable experts. Our service is designed to be user-friendly and accessible, ensuring you get the information you need without any hassle.

Are you struggling to find answers to your pressing questions? Do you need expert advice without the hefty consultation fees? WHAT.EDU.VN is your solution. We provide a free platform for you to ask any question and receive timely, accurate answers from experts in various fields.

9.1. Why Choose WHAT.EDU.VN?

- Free to Use: Ask any question without any charges.

- Quick Responses: Get timely answers to your queries.

- Expert Advice: Connect with knowledgeable professionals.

- User-Friendly Platform: Easy to navigate and use.

- Comprehensive Information: Access a wealth of knowledge on various topics.

9.2. Ready to Get Started?

Don’t let unanswered questions hold you back. Visit WHAT.EDU.VN today and experience the convenience of getting expert advice for free. Our community of experts is ready to provide you with the answers you need to make informed decisions and solve problems effectively.

Take Action Now: Visit what.edu.vn and ask your question today!

10. Stay Connected with WHAT.EDU.VN

Stay updated with the latest trends, tips, and offers in the world of personalization by following us on social media. Connect with us on Instagram and Facebook to ensure you don’t miss out on valuable insights and opportunities. Don’t forget to subscribe to our Blog and our YouTube channel for even more content.

We appreciate your feedback! If you found this article helpful, please leave a five-star rating.

See you soon in our next post!