A shunt, also known as a shunt resistor, is a vital component in electrical systems, particularly those utilizing battery monitors; it allows accurate real-time measurement of electrical current. Are you seeking a clear explanation of how shunts operate and their significance? At WHAT.EDU.VN, we provide comprehensive answers to your electrical inquiries, simplifying complex concepts. Dive in to discover the functionalities, applications, and types of electrical shunts and explore related concepts such as voltage drop and current measurement.

1. What is a Shunt and What Does It Do in Electrical Circuits?

A shunt is a device that allows electric current to pass around another point in the circuit by creating a low-resistance path. In electrical circuits, a shunt is primarily used to measure electric current, both alternating and direct, using an ammeter to measure the voltage drop across a low impedance resistor.

To elaborate, a shunt acts as a detour for current. Here’s a breakdown of its roles:

- Current Measurement: It allows precise measurement of current flow without interrupting the circuit.

- Overload Protection: By diverting excess current, it safeguards sensitive instruments from damage.

- Range Extension: Shunts enable ammeters to measure currents beyond their normal range.

- Circuit Modification: Engineers use shunts to modify circuit behavior for testing or specific applications.

1.1. Can You Explain Shunt Resistors in Simple Terms?

Shunt resistors are low-value resistors used to measure current by measuring the voltage drop across them, according to Ohm’s Law. Shunt resistors are designed with very low resistance values to minimize their impact on the circuit. They are essential for accurately measuring current in a wide range of applications, from battery monitoring to high-current power supplies.

1.2. What are the Key Characteristics of a Good Shunt Resistor?

A good shunt resistor has several important characteristics:

- Low Resistance Value: Essential to minimize impact on the circuit being measured.

- High Accuracy: Provides precise current measurements.

- Temperature Stability: Maintains performance consistency across varying temperatures.

- Low Temperature Coefficient of Resistance (TCR): Ensures minimal resistance change with temperature variations.

- High Power Rating: Capable of withstanding the power dissipated during current measurement.

- Four-Terminal Connection: Reduces errors by separating the current-carrying and voltage-sensing paths.

- Robust Construction: Offers durability and longevity in demanding environments.

1.3. What’s the Difference Between a Shunt and a Regular Resistor?

The primary differences between a shunt and a regular resistor lie in their function and characteristics:

| Feature | Shunt Resistor | Regular Resistor |

|---|---|---|

| Primary Use | Current measurement | Limiting current, voltage division, or creating resistance |

| Resistance | Very low (typically milliohms or microohms) | Varies widely (ohms to megaohms) |

| Accuracy | High, for precise measurements | Moderate to high, depending on tolerance |

| Power Rating | Can be high, depending on the current being measured | Varies, depending on the application |

| Configuration | Often four-terminal, to reduce measurement errors | Typically two-terminal |

| Temperature Stability | High, to maintain accuracy under varying temperatures | Moderate, depending on the resistor type |

Regular resistors are general-purpose components, whereas shunt resistors are specialized for accurate current measurement with minimal circuit impact.

1.4. How Does a Shunt Work with an Ammeter?

A shunt works with an ammeter by allowing the ammeter to measure high currents indirectly. The shunt, a low-value resistor, is placed in parallel with the ammeter. Most of the current flows through the shunt due to its low resistance, and only a small, proportional current flows through the ammeter. The ammeter measures the voltage drop across the shunt, which is then used to calculate the total current flowing through the circuit using Ohm’s Law.

1.5. What Is a Shunt Trip?

A shunt trip is a type of circuit breaker accessory that allows the breaker to be remotely tripped or opened by applying a voltage signal to the shunt trip coil. It is commonly used in emergency shutdown systems or automated control systems to quickly de-energize a circuit. Shunt trips provide a reliable and convenient way to remotely control circuit breakers, enhancing safety and operational efficiency.

2. What Are the Different Types of Shunts Available?

Shunts come in various designs to suit different applications and current ranges. Here are some common types:

- Fixed Shunts: These are standard, non-adjustable shunts used for measuring a specific current range.

- Removable Shunts: Designed for easy installation and replacement, often used in switchboards and control panels.

- Precision Shunts: High-accuracy shunts used in laboratory and calibration equipment.

- Surface Mount Shunts: Compact shunts designed for direct mounting on PCBs.

- Current Sensing Resistors: Low-value resistors specifically designed for current sensing in electronic circuits.

- Hall Effect Current Sensors: Non-intrusive sensors that measure current using the Hall effect, providing isolation and safety.

- Wireless Shunts: Advanced shunts that transmit current measurements wirelessly, ideal for remote monitoring.

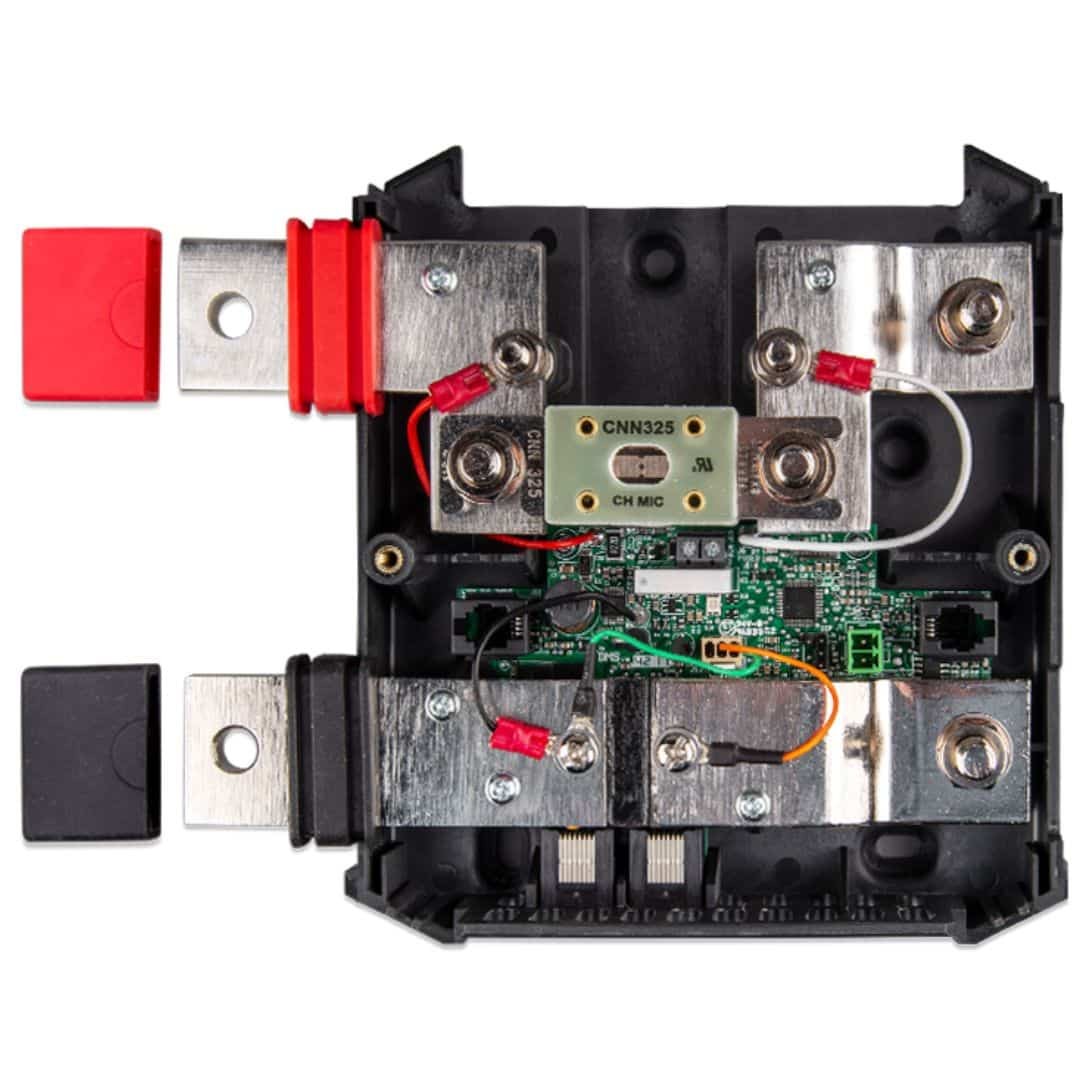

- Smart Shunts: Shunts with built-in microcontrollers for advanced data processing and communication.

Each type caters to specific requirements, balancing cost, accuracy, and ease of use.

2.1. What are Smart Shunts and Their Advantages?

Smart shunts are advanced current measurement devices with built-in microcontrollers that offer several advantages over traditional shunts:

- Data Processing: Smart shunts can process and analyze current data in real-time, providing more detailed information than just current values.

- Wireless Communication: They often include wireless communication capabilities (e.g., Bluetooth) for remote monitoring and data logging.

- Advanced Features: Smart shunts may offer features like overcurrent detection, temperature monitoring, and historical data analysis.

- Easy Integration: They can be easily integrated into IoT systems and smart grids for comprehensive energy management.

- Remote Calibration: Some smart shunts support remote calibration, reducing the need for manual maintenance.

Smart shunts enhance current measurement with advanced capabilities, making them ideal for modern applications.

3. What are the Applications of Shunts in Different Industries?

Shunts are used across various industries for precise current measurement and monitoring. Here are some key applications:

- Automotive Industry: Used in electric vehicles (EVs) and hybrid electric vehicles (HEVs) to monitor battery current and motor performance.

- Renewable Energy: Employed in solar and wind power systems to measure current flow and optimize energy generation.

- Industrial Automation: Essential in industrial control systems for monitoring motor currents, power supplies, and equipment performance.

- Aerospace: Used in aircraft power systems to monitor and control current in critical circuits.

- Medical Devices: Utilized in medical equipment such as MRI machines and X-ray systems for precise current measurement and safety.

- Telecommunications: Applied in telecom power supplies and base stations to monitor current and ensure reliable operation.

- Power Distribution: Used in substations and power grids to measure current flow and ensure grid stability.

- Battery Management Systems (BMS): Critical components in BMS for monitoring battery current, voltage, and temperature.

- Laboratory Equipment: Used in precision measurement instruments and calibration devices for accurate current readings.

3.1. How are Shunts Used in Electric Vehicles (EVs)?

In electric vehicles, shunts play a vital role in monitoring battery performance and ensuring efficient operation. Here’s how they are used:

- Battery Current Monitoring: Shunts measure the current flowing in and out of the battery pack, providing critical data for the Battery Management System (BMS).

- State of Charge (SOC) Calculation: Accurate current measurements from shunts help the BMS calculate the battery’s state of charge, ensuring optimal energy usage.

- Motor Control: Shunts monitor the current supplied to the electric motor, allowing precise control and preventing overloads.

- Regenerative Braking: They measure the current generated during regenerative braking, helping to optimize energy recovery.

- Safety Monitoring: Shunts help detect overcurrent conditions, protecting the battery and other components from damage.

- Thermal Management: Monitoring current helps manage the battery’s thermal performance by preventing overheating.

3.2. What Role Do Shunts Play in Solar Power Systems?

Shunts are essential components in solar power systems, playing a crucial role in monitoring and optimizing energy generation:

- Current Measurement: Shunts accurately measure the current produced by solar panels, providing data for system monitoring and optimization.

- Performance Monitoring: By tracking current, shunts help assess the performance of individual solar panels and the entire solar array.

- Maximum Power Point Tracking (MPPT): Shunts are used in MPPT controllers to optimize the power output of solar panels by adjusting the voltage and current.

- Grid Integration: They measure the current fed into the grid, ensuring compliance with utility requirements and grid stability.

- Fault Detection: Shunts help detect faults such as short circuits or ground faults in the solar array, enhancing system safety.

- Energy Storage: Used in battery-based solar systems to monitor the charging and discharging currents of the batteries.

3.3. How are Shunts Applied in Battery Management Systems (BMS)?

In Battery Management Systems (BMS), shunts are critical for precise monitoring and control of battery performance. Their key applications include:

- Current Measurement: Shunts accurately measure the current flowing into and out of the battery pack, providing essential data for the BMS.

- State of Charge (SOC) Estimation: Precise current measurements from shunts enable the BMS to accurately estimate the battery’s state of charge.

- State of Health (SOH) Monitoring: By tracking current over time, shunts help the BMS monitor the battery’s state of health and detect degradation.

- Overcurrent Protection: Shunts detect overcurrent conditions, allowing the BMS to protect the battery from damage.

- Charge Control: Used to control the charging process, ensuring the battery is charged safely and efficiently.

- Load Management: Shunts help manage the load on the battery by monitoring the current drawn by various components.

- Data Logging: The BMS uses current data from shunts to log historical performance, facilitating analysis and optimization.

4. How Do You Choose the Right Shunt for Your Application?

Selecting the right shunt involves considering several factors to ensure accurate and reliable current measurement:

- Current Range: Determine the maximum current you need to measure and choose a shunt with a suitable current rating.

- Accuracy: Select a shunt with the required accuracy for your application. Precision shunts offer higher accuracy for critical measurements.

- Voltage Drop: Consider the voltage drop across the shunt at maximum current, as this can affect circuit performance.

- Resistance Value: Choose a shunt with a low resistance value to minimize its impact on the circuit.

- Temperature Coefficient: Select a shunt with a low-temperature coefficient to maintain accuracy over varying temperatures.

- Physical Size: Consider the physical size and mounting requirements of the shunt to ensure it fits in your application.

- Environmental Conditions: Choose a shunt that can withstand the environmental conditions in your application, such as temperature, humidity, and vibration.

- Compliance Standards: Ensure the shunt meets relevant compliance standards for your industry and application.

- Cost: Balance performance requirements with cost considerations to select a shunt that provides the best value.

- Manufacturer Reputation: Choose a shunt from a reputable manufacturer known for quality and reliability.

4.1. What is Ampacity and How Does It Affect Shunt Selection?

Ampacity refers to the maximum amount of electric current a conductor or device can carry before overheating and potentially causing damage. When selecting a shunt, ampacity is a critical factor. The shunt must have an ampacity rating equal to or greater than the maximum current expected in the circuit. If the shunt’s ampacity is too low, it can overheat, leading to inaccurate readings, damage, or even failure.

Here’s how ampacity affects shunt selection:

- Determining Maximum Current: Identify the highest possible current the shunt will need to measure.

- Selecting the Right Shunt: Choose a shunt with an ampacity rating that exceeds the maximum current to provide a safety margin.

- Preventing Overheating: Ensure the shunt can handle the current without overheating, which can affect accuracy and longevity.

- Ensuring Safety: Using a shunt with adequate ampacity prevents potential hazards such as fire or equipment damage.

4.2. How Do You Match a Shunt with a Battery Monitor?

Matching a shunt with a battery monitor is essential for accurate battery monitoring. Follow these steps to ensure compatibility:

- Check the Battery Monitor’s Specifications: Determine the shunt requirements specified by the battery monitor manufacturer, including the current range and output voltage.

- Select the Correct Shunt: Choose a shunt with a current range that matches or exceeds the maximum current of your battery system.

- Verify Output Voltage: Ensure the shunt’s output voltage (usually in millivolts) is compatible with the battery monitor’s input range. Common values are 50mV, 75mV, or 100mV at the shunt’s rated current.

- Consider Accuracy: Select a shunt with the appropriate accuracy for your application. Higher accuracy shunts provide more precise measurements.

- Check Temperature Stability: Opt for a shunt with a low-temperature coefficient to minimize the impact of temperature variations on accuracy.

- Install Properly: Follow the manufacturer’s instructions for proper installation, including wiring and connections, to ensure accurate readings.

4.3. What is the Standard Output Voltage for Shunts and Why is It Important?

The standard output voltage for shunts is typically 50mV, 75mV, or 100mV at the shunt’s rated current. This output voltage represents the voltage drop across the shunt when it is carrying its maximum rated current. The specific output voltage is crucial because it must match the input requirements of the measuring instrument or battery monitor connected to the shunt.

Here’s why the output voltage is important:

- Compatibility: The measuring instrument is designed to accurately read a specific voltage range. If the shunt’s output voltage doesn’t match this range, the readings will be inaccurate.

- Calibration: Instruments are often calibrated based on the shunt’s output voltage, ensuring precise measurements.

- Standardization: Using standard output voltages allows for easy interchangeability and compatibility between different shunts and measuring devices.

- Accuracy: Matching the output voltage ensures the instrument operates within its designed range, maintaining measurement accuracy.

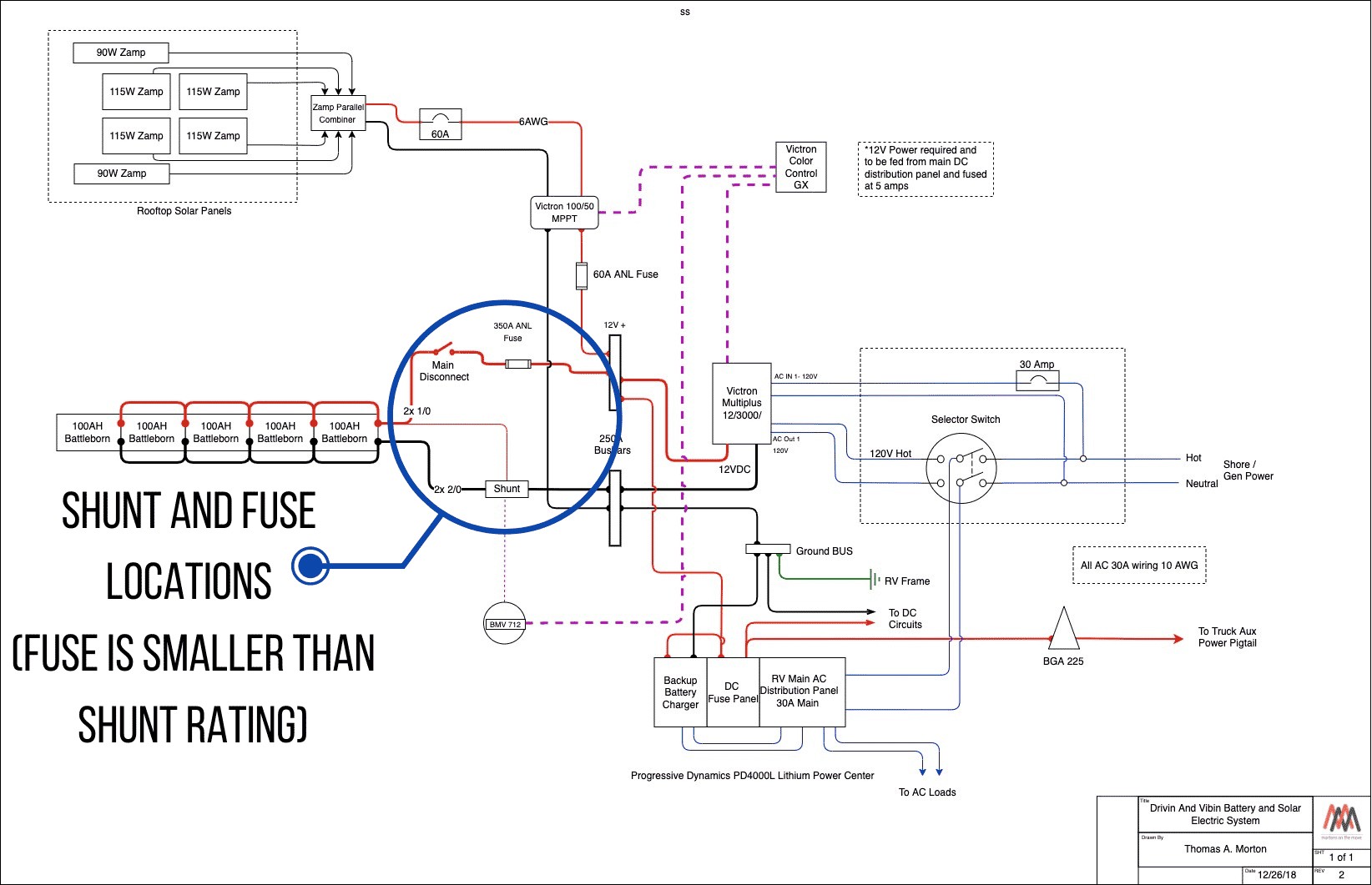

5. Where Should You Mount an Electrical Shunt?

The placement of an electrical shunt is crucial for accurate current measurement. Here are general guidelines:

- Close to the Battery: For battery monitoring, mount the shunt on the negative lead close to the battery bank to capture all current entering and exiting the batteries.

- Before Branching Circuits: Ensure the shunt is placed before any branching circuits so that it measures the total current.

- Stable Mounting: Securely mount the shunt to prevent vibration and mechanical stress, which can affect accuracy.

- Clean Connections: Ensure all connections to the shunt are clean and tight to minimize resistance and ensure accurate readings.

- Protected Environment: Protect the shunt from harsh environmental conditions such as moisture, dust, and extreme temperatures.

- Accessibility: Mount the shunt in a location that is easily accessible for inspection and maintenance.

- Away from Heat Sources: Avoid mounting the shunt near heat sources, as temperature variations can affect its accuracy.

5.1. Does the Shunt Need to Be Close to the Battery Bank?

Yes, when using a shunt to measure battery capacity, it is best to install it close to the battery bank. Here’s why:

- Accurate Battery Voltage Sensing: The shunt needs to have an accurate battery voltage sensor to provide precise readings.

- Capture All Power Flow: It must include all power going into and out of the batteries to measure capacity accurately.

- Avoid Direct Connections: Nothing should be connected directly to the batteries beside the shunt on the negative lead, or it will not measure correctly.

- Minimize Interference: Proximity to the battery bank minimizes interference from other circuits and components.

5.2. Can a Shunt Be Installed Anywhere in a Circuit?

While shunts are commonly used near the battery bank for battery monitoring, they can be installed anywhere in a circuit where you need to measure electrical current. Here are some considerations:

- Specific Current Measurement: Install the shunt in the path of the specific current you want to measure.

- Examples of Placement: Common places to install shunts include alternators in vehicles, solar panels, wind turbines, etc.

- Calculating Current Flow: The main goal is to calculate the current flowing out of a certain electrical system, so place the shunt accordingly.

- Consider Accuracy: Ensure the shunt is placed in a location where it can provide accurate measurements without interference.

5.3. How Does Shunt Placement Affect Measurement Accuracy?

Shunt placement significantly affects measurement accuracy. Here’s how:

- Capturing Total Current: The shunt must capture the total current you want to measure. If it’s placed after a branch, it will only measure the current in that branch.

- Minimizing External Interference: Placing the shunt away from sources of electromagnetic interference (EMI) ensures cleaner readings.

- Stable Voltage Reference: Ensure the shunt has a stable voltage reference point for accurate voltage drop measurements.

- Avoiding Ground Loops: Proper placement helps avoid ground loops, which can introduce errors in current measurements.

- Consistent Temperature: Avoid placing the shunt near heat sources, as temperature variations can affect its resistance and accuracy.

6. What Are Some Common Problems with Shunts and How Can You Troubleshoot Them?

Common problems with shunts include inaccurate readings, overheating, and physical damage. Here’s how to troubleshoot them:

- Inaccurate Readings:

- Check Connections: Ensure all connections are clean, tight, and free of corrosion.

- Verify Shunt Rating: Confirm the shunt is properly matched to the battery monitor and the current range.

- Calibrate: Calibrate the battery monitor and shunt according to the manufacturer’s instructions.

- Check for Interference: Ensure there is no external interference affecting the readings.

- Overheating:

- Verify Current Load: Ensure the current flowing through the shunt is within its rated ampacity.

- Check for Overloads: Identify and address any overloads in the circuit.

- Ensure Proper Ventilation: Provide adequate ventilation around the shunt to dissipate heat.

- Check for Damage: Inspect the shunt for any signs of physical damage or degradation.

- Physical Damage:

- Inspect for Cracks: Check for any cracks or breaks in the shunt material.

- Check for Corrosion: Look for signs of corrosion, especially in harsh environments.

- Replace if Damaged: Replace the shunt if any physical damage is found.

- General Troubleshooting Steps:

- Review Wiring: Ensure all wiring is correct and follows the manufacturer’s recommendations.

- Use a Multimeter: Use a multimeter to verify the voltage drop across the shunt and confirm it matches the expected value.

- Consult Manuals: Refer to the manuals for both the shunt and the battery monitor for specific troubleshooting steps.

6.1. What Causes a Shunt to Overheat?

A shunt overheats when it is forced to carry more current than it is designed to handle. Several factors can cause this:

- Exceeding Ampacity: The most common cause is exceeding the shunt’s rated ampacity, which leads to excessive heat generation.

- Overloads: Circuit overloads can cause the shunt to carry more current than intended.

- Short Circuits: Short circuits can result in very high current flows, causing the shunt to overheat rapidly.

- Poor Connections: Loose or corroded connections can increase resistance, leading to localized heating at the connection points.

- Inadequate Ventilation: Insufficient ventilation can prevent heat from dissipating, causing the shunt to overheat.

- Environmental Factors: High ambient temperatures can exacerbate overheating issues.

6.2. How Can You Tell if a Shunt is Failing?

Several signs indicate that a shunt is failing:

- Inaccurate Readings: The most common sign is consistently inaccurate current readings.

- Overheating: The shunt may become excessively hot to the touch, even at normal current levels.

- Visible Damage: Physical damage such as cracks, breaks, or corrosion can indicate failure.

- Burn Marks: Burn marks or discoloration on the shunt or surrounding components can suggest overheating and failure.

- Erratic Behavior: The battery monitor may display erratic or fluctuating readings.

- Complete Failure: In some cases, the shunt may completely fail, resulting in no current readings.

6.3. What are Some Best Practices for Maintaining Shunts?

To ensure the long-term accuracy and reliability of shunts, follow these best practices for maintenance:

- Regular Inspections: Periodically inspect shunts for signs of physical damage, corrosion, or overheating.

- Clean Connections: Keep all connections clean and tight to minimize resistance and ensure accurate readings.

- Verify Wiring: Ensure all wiring is correct and follows the manufacturer’s recommendations.

- Calibrate Regularly: Calibrate the battery monitor and shunt according to the manufacturer’s instructions.

- Monitor Load: Ensure the current flowing through the shunt remains within its rated ampacity.

- Provide Ventilation: Ensure adequate ventilation around the shunt to dissipate heat.

- Protect from Environment: Protect the shunt from harsh environmental conditions such as moisture, dust, and extreme temperatures.

- Record Maintenance: Keep a record of all inspections, maintenance, and calibrations performed on the shunt.

7. Can a Shunt Be Used for Both AC and DC Current Measurement?

Yes, a shunt can be used for both AC and DC current measurement. However, the specific type of shunt and measuring instrument may differ depending on the application:

- DC Shunts: Designed for measuring direct current (DC) and typically use a basic resistive element.

- AC Shunts: Can be used for measuring alternating current (AC), but require consideration of factors such as frequency response and impedance.

- True RMS Measurement: For accurate AC current measurement, especially with non-sinusoidal waveforms, use a true RMS (Root Mean Square) measuring instrument.

- Current Transformers: For high AC currents, current transformers (CTs) are often used instead of shunts for safety and isolation.

8. What Are the Safety Precautions When Working With Shunts?

Working with shunts involves electrical circuits, so it’s important to take safety precautions:

- De-energize Circuits: Always de-energize the circuit before installing, inspecting, or maintaining shunts.

- Use Insulated Tools: Use insulated tools to prevent electric shock.

- Wear Protective Gear: Wear appropriate personal protective equipment (PPE) such as safety glasses and gloves.

- Follow Instructions: Follow the manufacturer’s instructions for installation, operation, and maintenance.

- Verify Connections: Ensure all connections are secure and properly insulated.

- Avoid Moisture: Keep shunts and related equipment dry to prevent electrical hazards.

- Proper Grounding: Ensure proper grounding to minimize the risk of electric shock.

- Qualified Personnel: Only qualified personnel should work with electrical shunts and related equipment.

9. Are There Alternatives to Using Shunts for Current Measurement?

Yes, there are alternatives to using shunts for current measurement, each with its own advantages and disadvantages:

- Hall Effect Sensors: These non-contact sensors measure the magnetic field produced by the current, providing isolation and safety.

- Current Transformers (CTs): Used for measuring high AC currents, CTs provide isolation and can handle very high currents.

- Rogowski Coils: Flexible coils that measure AC current by sensing the rate of change of current.

- Current Clamps: Portable devices that clamp around a wire to measure current without interrupting the circuit.

- Fluxgate Magnetometers: Highly sensitive sensors used for measuring very small currents.

The choice depends on factors such as current range, accuracy requirements, isolation needs, and cost considerations.

10. Where Can You Find More Information and Help with Electrical Shunts?

For more information and help with electrical shunts, you can explore the following resources:

- Manufacturer Websites: Visit the websites of shunt manufacturers for product specifications, application notes, and technical support.

- Online Forums: Participate in online forums and communities related to electronics and electrical engineering.

- Educational Websites: Explore educational websites and online courses that cover electrical engineering topics.

- Industry Publications: Read industry publications and journals for the latest research and developments in current measurement technology.

- Technical Books: Consult technical books on electrical engineering and instrumentation for detailed information.

- Professional Associations: Join professional associations such as the IEEE (Institute of Electrical and Electronics Engineers) for access to resources and networking opportunities.

Remember, reliable information is key to understanding and safely working with electrical shunts. If you have more questions, don’t hesitate to ask the experts at WHAT.EDU.VN, where answering your questions is always free. Contact us at 888 Question City Plaza, Seattle, WA 98101, United States, Whatsapp: +1 (206) 555-7890. Visit our website WHAT.EDU.VN today!

Do you have any electrical questions? Ask them on what.edu.vn today and get free answers!