You’ve likely encountered clothing labels proudly stating “100% polyester.” But What Is Polyester exactly, and why is it so ubiquitous? This synthetic marvel has woven its way into countless aspects of our lives, from the clothes we wear to the homes we live in. Let’s delve into the world of polyester to understand its origins, manufacturing, properties, and the diverse applications that make it a cornerstone of modern textiles and beyond.

Defining Polyester: More Than Just a Label

Polyester is a human-made synthetic fiber, a testament to chemical innovation. Its formal name, polyethylene terephthalate (PET), might sound complex, but its creation is rooted in a combination of ethylene glycol and terephthalic acid – chemical building blocks meticulously combined in a laboratory. Essentially, polyester is a type of plastic transformed into fiber form.

Renowned for its robust strength and remarkable ability to hold its shape, polyester serves as a fundamental component in a vast array of industrial, commercial, and household products. While it once carried a less-than-stellar reputation regarding environmental impact, advancements in sustainable practices are paving the way for more eco-conscious polyester production. Continue reading to discover the compelling attributes of polyester and its widespread influence.

The Journey of Polyester: From Petroleum to Fabric

Unlike natural fibers such as cotton that sprout from plants, polyester’s origins lie in a chemical process. While the precise method can vary depending on the specific type of polyester and manufacturer, the creation of this versatile fiber generally follows five core steps:

-

Monomer Creation: The journey begins with petroleum, extracted from the earth and transported to refineries. Here, petroleum is broken down into its constituent parts, some of which become essential ingredients for various applications. Ethylene and p-xylene, extracted from petroleum, are the two crucial monomers needed for polyester production.

-

Polymer Formation: These monomers are then combined with dimethyl terephthalate, triggering a chemical reaction that creates the polymer polyethylene terephthalate (PET). Notably, PET in this form is the same plastic used to produce common soda and water bottles. At this stage, PET exhibits a viscous, honey-like consistency.

-

Polymer Extrusion: The newly formed PET polymer is then extruded, a process where it’s forced through openings to create strands. This extrusion allows the PET to cool and solidify. Subsequently, these solidified strands are cut into small pellets.

-

Melting and Spinning Pellets: The PET pellets undergo a second melting phase. This molten PET is then pushed through spinnerets – devices with tiny holes – to form continuous threads. As these long threads cool, they harden into polyester fibers. Interestingly, the shape of the spinneret holes can be modified to create fibers with different qualities, tailoring them for specific applications.

-

Yarn is Born: Finally, these individual fibers are twisted together to create polyester yarn, ready to be woven or knitted into fabric. At this stage, the fibers can be further customized through cutting or chemical treatments to achieve desired properties.

This manufacturing process offers flexibility. Modifications can be introduced to achieve specific characteristics. For example, to create fabrics with a soft and smooth texture, the fibers are adjusted to form a thin filament. Furthermore, the source of ethylene can be altered. In the production of plant-based polyester, ethylene is derived from sustainable sources like sugarcane rather than petroleum, reflecting a move towards greener alternatives.

Polyester Properties: Why It’s So Popular

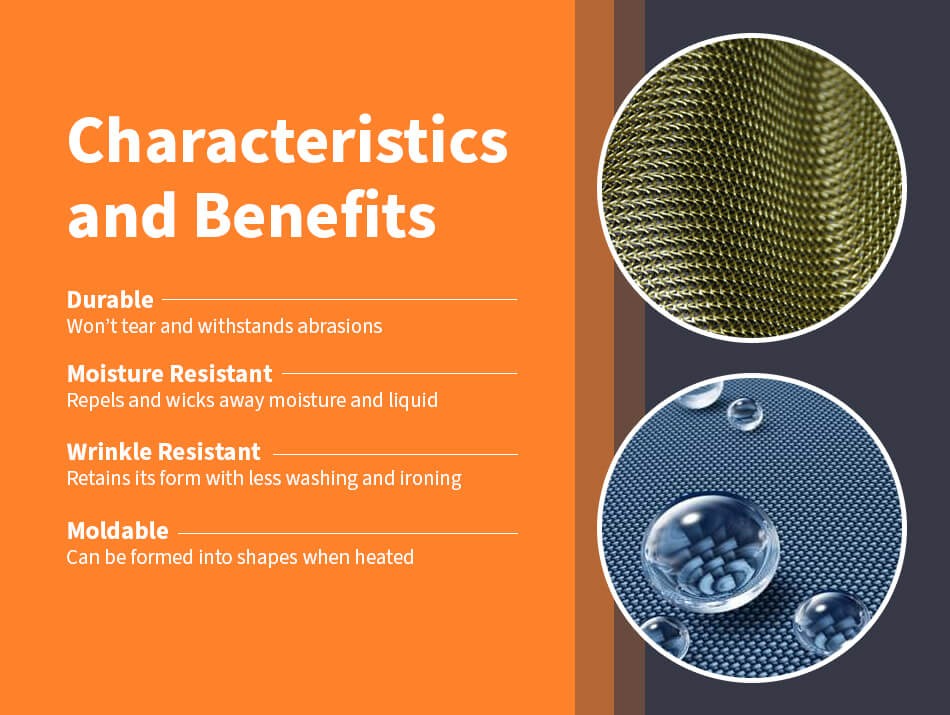

Polyester’s widespread adoption stems from its remarkable array of inherent properties, many of which are unique to this manufactured fabric. These benefits have propelled polyester to its current popularity and continued widespread use. Key characteristics of polyester include:

Durability

Polyester fibers exhibit superior strength compared to many natural fibers. It resists tearing and stretching, and boasts excellent abrasion resistance. Its resilience extends to environmental factors, as polyester is highly resistant to degradation from heat, light, and ultraviolet (UV) radiation. This durability makes it a prime material for demanding applications like boat covers and items exposed to prolonged sunlight. Furthermore, polyester is easy to wash, quick to dry, and resistant to mildew and most chemicals. These attributes contribute to its frequent use in outdoor clothing and gear such as jackets, tents, and backpacks, as well as in home furnishings, safety belts, carpets, and even laundry bags. Its versatility is such that polyester even finds application as a synthetic artery replacement in medical procedures.

Moisture Resistance

Polyester is inherently hydrophobic, meaning it repels moisture. Instead of absorbing liquids like cotton, polyester wicks away liquid droplets, channeling moisture away from the surface. This characteristic further enhances its suitability for outdoor clothing and gear. A polyester tent, for example, will effectively resist rain and moisture, keeping the interior dry. However, this moisture resistance can also make polyester less breathable. To address this, clothing manufacturers often blend polyester with more breathable materials like cotton to create garments that offer both water resistance and comfort.

Wrinkle Resistance

Polyester excels at retaining its shape, requiring less frequent washing and ironing compared to fabrics like cotton or linen. Its wrinkle-resistant nature allows it to maintain a smooth and presentable appearance, making it suitable for extended wear between washes. This easy-care quality was a major selling point when polyester was first introduced as an alternative apparel material, offering convenience and low maintenance.

Moldability & Recyclability

When exposed to heat, polyester becomes highly moldable and can be shaped into various forms. Importantly, it can be re-melted and reused multiple times, reducing waste destined for landfills. In a further stride towards sustainability, specialized companies are now focusing on separating poly/cotton blends, enabling the recovery and reuse of polyester fibers in new textiles, promoting a circular economy.

Texture & Comfort

Like any fabric, polyester has aspects that may be less appealing to some consumers or less suitable for certain applications. One common point is that most polyester types are not biodegradable, although research is actively underway to develop biodegradable polyester alternatives that break down at a rate comparable to natural materials like cotton.

Another consideration is texture. Polyester, in its pure form, is not inherently luxurious and can sometimes feel coarse, especially against sensitive skin. The perceived texture can vary based on fiber manufacturing and construction techniques. While some polyester fabrics can feel rough or itchy, others can be crafted to be surprisingly smooth and silky. To enhance comfort, particularly in clothing, manufacturers often blend polyester with other fibers to create more comfortable and appealing garments.

Types of Polyester: Tailoring to Different Needs

While often referred to as a single entity, “polyester” encompasses several distinct types, primarily differentiated by their chemical composition and manufacturing processes. These variations result in unique characteristics that make certain polyester types more appropriate for specific applications. Let’s examine three prevalent types of polyester fabric:

Polyethylene Terephthalate (PET)

Polyethylene terephthalate stands as the most widely used and recognized type of polyester. Commonly known as PET, it holds the title of the most produced polyester globally. PET’s popularity stems from its combination of durability and cost-effectiveness in production, making it a versatile choice for a broad spectrum of applications. From clothing and packaging to industrial components, PET polyester’s robust nature and affordable price point contribute to its pervasive presence.

Plant-Based Polyester

While conventional polyester enjoys recyclability, its recycling predominantly occurs in the form of bottles rather than textile fibers. Alarmingly, less than 15% of polyester used in fabrics and clothing is actually recycled and reintegrated into new textiles. Plant-based polyester emerges as a more sustainable alternative in this context.

Plant-based polyester distinguishes itself by utilizing bio-derived alternatives to petroleum in its production. The crucial ethylene component, essential for polyester creation, is sourced from renewable resources like sugarcane or bio-waste. Bio-waste encompasses predominantly organic materials such as food scraps and sawdust. Employing these biodegradable materials significantly reduces reliance on petroleum resources, lessening the environmental footprint.

Although plant-based polyester production volume is currently lower than PET due to higher production costs, it offers a compelling environmental advantage. Plant-based polyester fabric is inherently biodegradable, aligning with principles of sustainability. Provided that the source crops are farmed responsibly, this polyester type presents a more environmentally conscious option. While potentially not as widely accessible or possessing the same level of durability as PET, plant-based polyester represents a significant stride towards eco-friendlier textile solutions.

PCDT Polyester

PCDT polyester shares similarities with PET but exhibits a distinct chemical structure. PCDT is an abbreviation for poly-1, 4-cyclohexylene-dimethylene terephthalate, the complex molecule that defines this polyester variant. Despite often exhibiting enhanced elasticity and durability compared to PET, PCDT polyester remains less common in overall production volume. These superior properties, however, make PCDT polyester well-suited for demanding, heavy-duty applications where resilience and stretch are paramount, such as curtains and upholstery fabrics designed for long-term wear and tear.

Uses of Polyester

Polyester’s versatility is reflected in its presence across numerous products and industries. Its inherent durability makes it an ideal material for a diverse range of items, spanning from everyday clothing to specialized consumer products and demanding industrial applications:

Clothing & Apparel

Polyester fiber’s adaptability allows it to replace cotton fibers in virtually any clothing application. Apparel items for business, formal occasions, and casual wear can all be crafted from polyester. From foundational items like socks and underwear to sophisticated suits and everyday shirts, polyester fabric offers limitless possibilities in the realm of apparel. Its wrinkle resistance and durability make it a practical choice for daily wear.

Housewares

Polyester extends its utility into the home, finding use in various housewares such as microfiber towels, cozy blankets, decorative curtains, and durable upholstery. Its moisture-resistant properties make polyester a particularly effective fabric for items prone to spills and moisture exposure, such as pillows, chair cushions, and sofa cushions, offering both practicality and longevity.

Automotive Industry

Step into a car and fasten your seatbelt – chances are, it’s made with polyester. Beyond safety belts, polyester serves as a reinforcement material in car tires, enhancing strength and extending tire lifespan. Its robust nature contributes to vehicle safety and performance in critical components.

Geosynthetics

Polyester plays a crucial role in civil engineering and construction projects within the realm of geosynthetics. It can be found integrated into roads and landfills, where its properties are leveraged for effective water filtration, drainage systems, and soil erosion control. Its durability and resistance to degradation in harsh environments make it a reliable material in infrastructure development.

Industrial Applications

Beyond consumer-facing products, polyester material extends into numerous industrial applications. It is used in the production of bottles (particularly PET), ropes, cords, boats, LCD screens, tarps, food containers, and various other industrial products. Its strength, chemical resistance, and moldability make it a valuable material across diverse industrial sectors.

Polyester is also commonly employed as stuffing material for blankets, bedding, and sleeping bags due to its excellent insulation capabilities. Many everyday items rely on polyester, often without us even realizing its presence, highlighting its silent yet significant contribution to modern living.

The Economics of Polyester: Understanding the Cost Factors

The price of polyester is subject to fluctuations, influenced by a complex interplay of supply and demand dynamics, fiber quality, sourcing location, and the degree of raw material processing involved. While historically, polyester pricing exhibited relative stability, particularly before 2016, the market has since experienced increased volatility, further amplified by the onset of the global pandemic.

Several key factors underpin polyester pricing:

Price of Raw Materials: Polyethylene Terephthalate (PET), the foundation of polyester, is produced by combining Mono-Ethylene Glycol (MEG) and Purified Terephthalic Acid (PTA), both derived from crude oil. Consequently, fluctuations in crude oil prices directly impact the cost of PTA, and subsequently, the overall cost of polyester production.

Ocean Freight: China dominates global industrial polyester production, accounting for approximately 70% of worldwide output. This geographical concentration necessitates ocean freight for international distribution. Increases in shipping costs directly translate to higher polyester prices. Pandemic-related disruptions have further exacerbated this, slowing international shipping and creating polyester acquisition challenges, leading to price hikes.

Market Demand: While polyester finds applications across numerous industries, the automotive sector exerts significant influence on overall demand. Polyester is integral to various car components, including seatbelts, tire carcass plies, airbags, hose reinforcement, power transmission belt reinforcement, and interiors. Slowdowns in automobile production, such as those caused by computer chip shortages, consequently impact polyester demand and supply dynamics, affecting market pricing. The fundamental principle of supply and demand directly governs market pricing for polyester.

Quality Polyester Fabrics from Apex Mills

If your endeavors require high-quality polyester fabric solutions, Apex Mills stands ready to assist. Our team of fabric specialists has a proven track record of satisfying customers across diverse fields, from healthcare to the military, delivering tailored textile solutions to meet their specific requirements.

Contact our team today to discover how we can develop a customized polyester solution for your unique needs.