What Is A Conduit? It’s a question that often arises in various fields, from electrical engineering to animation design. At WHAT.EDU.VN, we aim to demystify this term, providing clear explanations and practical examples. Discover its applications and benefits, and explore related concepts like electrical raceways and cable management solutions.

1. What Is A Conduit? A Comprehensive Definition

A conduit, in its most basic sense, is a protective tube or channel designed to house and safeguard electrical wiring, cables, or other utilities. Think of it as a fortress for your wires, shielding them from potential damage and ensuring a safe, organized, and reliable system.

- Purpose: To protect wires from physical damage, moisture, corrosion, and other environmental hazards.

- Materials: Typically made of metal (steel, aluminum) or non-metal (PVC, fiberglass).

- Applications: Used in both residential, commercial, and industrial settings, as well as in animation and game design.

2. Why Are Conduits Important? Key Benefits

Conduits offer a multitude of advantages, making them an indispensable component in various applications. Here’s a breakdown of their key benefits:

- Protection: Shields wires and cables from physical damage, such as impacts, abrasions, and crushing forces.

- Safety: Reduces the risk of electrical shocks, fires, and other hazards by containing and insulating wires.

- Organization: Provides a neat and organized way to manage wires and cables, preventing tangling and clutter.

- Compliance: Helps meet electrical codes and regulations, ensuring a safe and compliant installation.

- Durability: Extends the lifespan of wires and cables by protecting them from environmental factors like moisture, corrosion, and UV radiation.

- Flexibility: Allows for easy modification and expansion of electrical systems as needed.

- Aesthetics: Can be concealed within walls or ceilings, providing a clean and professional appearance.

- Accessibility: Facilitates easy access to wires for maintenance, repairs, and upgrades.

3. Types of Conduits: A Detailed Overview

Conduits come in a variety of types, each designed for specific applications and environments. Here’s a rundown of the most common types:

- Rigid Metal Conduit (RMC): Heavy-duty galvanized steel conduit used for maximum protection in harsh environments.

- Pros: Excellent protection, high strength, durable.

- Cons: Heavy, difficult to bend, expensive.

- Intermediate Metal Conduit (IMC): A lighter-weight version of RMC, offering good protection at a lower cost.

- Pros: Good protection, lighter than RMC, more affordable.

- Cons: Less durable than RMC, requires specialized tools for bending.

- Electrical Metallic Tubing (EMT): Thin-walled steel conduit, also known as “thin-wall” conduit, commonly used in commercial and residential applications.

- Pros: Lightweight, easy to bend, relatively inexpensive.

- Cons: Less protection than RMC or IMC, not suitable for harsh environments.

- Flexible Metal Conduit (FMC): Flexible steel conduit used for connections to motors, appliances, and other equipment that require movement.

- Pros: Highly flexible, easy to install in tight spaces.

- Cons: Less protection than rigid conduits, requires specialized fittings.

- Liquidtight Flexible Metal Conduit (LFMC): Flexible metal conduit with a waterproof jacket, used in wet or corrosive environments.

- Pros: Waterproof, flexible, good protection against corrosion.

- Cons: More expensive than FMC, limited flexibility compared to FMC.

- Rigid PVC Conduit: Non-metallic conduit made of polyvinyl chloride (PVC), commonly used in underground and corrosive environments.

- Pros: Corrosion-resistant, lightweight, easy to install.

- Cons: Less protection than metal conduits, susceptible to damage from UV radiation.

- Electrical Nonmetallic Tubing (ENT): Flexible non-metallic conduit, often referred to as “smurf tube,” used in walls, floors, and ceilings.

- Pros: Lightweight, flexible, easy to install, inexpensive.

- Cons: Less protection than metal conduits, not suitable for exposed locations.

4. Conduit Materials: Choosing the Right Option

The material of a conduit plays a crucial role in its performance and suitability for specific applications. Here’s a comparison of common conduit materials:

| Material | Pros | Cons | Applications |

|---|---|---|---|

| Steel | High strength, durable, excellent protection | Heavy, susceptible to corrosion (unless galvanized), more expensive | Harsh environments, industrial settings, areas requiring maximum protection |

| Aluminum | Lightweight, corrosion-resistant, non-magnetic | Less strong than steel, more expensive | Corrosive environments, areas where weight is a concern, applications requiring non-magnetic properties |

| PVC | Corrosion-resistant, lightweight, inexpensive | Less strong than metal, susceptible to UV damage | Underground applications, corrosive environments, residential and commercial buildings |

| Fiberglass | Corrosion-resistant, lightweight, non-conductive | More expensive than PVC, can be brittle | Corrosive environments, areas requiring non-conductive properties, wastewater treatment plants |

| Flexible Metal | Highly flexible, easy to install in tight spaces | Less protection than rigid conduits, requires specialized fittings | Connections to motors, appliances, and other equipment that require movement |

| Liquidtight Metal | Waterproof, flexible, good protection against corrosion | More expensive than FMC, limited flexibility compared to FMC | Wet or corrosive environments, outdoor applications |

| Nonmetallic | Lightweight, flexible, easy to install, inexpensive | Less protection than metal conduits, not suitable for exposed locations | Walls, floors, and ceilings in residential and commercial buildings, areas where flexibility is required |

5. Conduit Sizes: Ensuring Proper Fit

Conduits are available in various sizes to accommodate different numbers and sizes of wires or cables. Selecting the correct size is crucial for ensuring proper airflow, preventing overheating, and complying with electrical codes.

- Nominal Size: Conduits are typically identified by their nominal size, which is the approximate inside diameter in inches.

- Fill Capacity: Electrical codes specify the maximum percentage of the conduit’s cross-sectional area that can be occupied by wires.

- Calculation: To determine the appropriate conduit size, you need to calculate the total cross-sectional area of all the wires or cables that will be installed in the conduit and ensure that it does not exceed the allowable fill capacity.

- Tables and Charts: Electrical codes provide tables and charts that list the allowable fill capacity for different conduit sizes and wire types.

6. Conduit Installation: Best Practices

Proper conduit installation is essential for ensuring the safety, reliability, and longevity of an electrical system. Here are some best practices to follow:

- Planning: Plan the conduit layout carefully, considering the location of equipment, obstacles, and access points.

- Cutting: Use appropriate tools to cut conduits to the desired length, ensuring clean and square cuts.

- Bending: Use conduit benders to create smooth and accurate bends without damaging the conduit.

- Deburring: Remove any sharp edges or burrs from the cut ends of the conduit to prevent damage to wires.

- Joining: Use appropriate fittings to connect conduit sections, ensuring a secure and watertight connection.

- Support: Support conduits properly using clamps, straps, or hangers, according to electrical code requirements.

- Grounding: Ground metal conduits properly to prevent electrical shock hazards.

- Pulling Wires: Use pulling lubricant to ease the installation of wires and prevent damage to the insulation.

- Inspection: Inspect the completed installation to ensure that all connections are secure, supports are in place, and the system meets electrical code requirements.

7. Conduit Fittings: Connecting and Securing

Conduit fittings are essential components that connect conduit sections, provide access points, and secure conduits to boxes and equipment. Here are some common types of conduit fittings:

- Couplings: Used to connect two sections of conduit together.

- Connectors: Used to connect conduit to boxes, enclosures, or equipment.

- Elbows: Used to change the direction of a conduit run.

- Tees: Used to create a branch in a conduit run.

- Unions: Used to join two sections of conduit that cannot be rotated.

- Bushings: Used to protect wires from abrasion as they enter or exit a conduit.

- Locknuts: Used to secure connectors and bushings to boxes and enclosures.

- Straps and Clamps: Used to support conduits and secure them to walls, ceilings, or other surfaces.

8. Conduit Applications: Where Are They Used?

Conduits are used in a wide range of applications, providing protection and organization for electrical wiring in various environments. Here are some common examples:

- Residential Buildings: Protecting wiring in walls, floors, and ceilings.

- Commercial Buildings: Powering lighting, equipment, and other electrical systems.

- Industrial Facilities: Supporting heavy-duty electrical systems and protecting wiring from harsh conditions.

- Underground Wiring: Protecting underground cables from moisture, corrosion, and physical damage.

- Outdoor Applications: Providing weather-resistant protection for outdoor lighting, signage, and equipment.

- Hazardous Locations: Containing sparks and explosions in areas with flammable gases or dust.

- Telecommunications: Routing and protecting communication cables.

- Transportation: Protecting wiring in vehicles, trains, and aircraft.

9. Conduit in Animation and Game Design

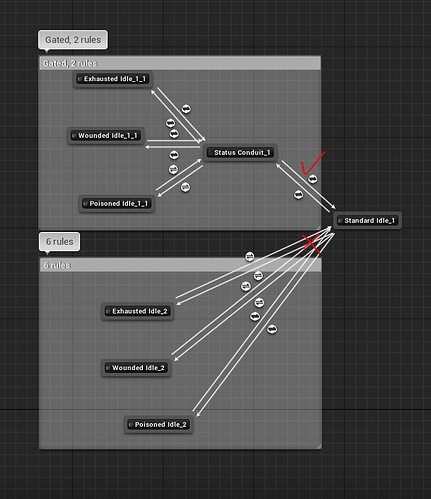

In animation and game design, a conduit serves as a gate or switch, controlling the flow of animation states and logic within a state machine.

- State Machines: Animation systems often use state machines to manage different animation states (e.g., idle, walking, running, jumping).

- Conduits as Gates: A conduit acts as a conditional gate, determining whether a transition between states should occur based on certain conditions (e.g., player input, game events).

- Simplified Logic: Conduits help simplify complex animation logic by encapsulating conditions and preventing the need to manage numerous rules simultaneously.

- Performance Optimization: By using conduits as gates, the system only needs to evaluate the conditions for the active conduit, reducing the computational load and improving performance.

Let’s say your character can have different status effects put on them, that drastically affects how they look when moving (Exhausted, Wounded and Poisoned) Inside of each of those you have states (Idle, Walk/Run, Jump) that have their own Bool/Rules. You can copy that entire setup, rules and all, gate it behind a conduit like “Status” replace the animations with different versions and you now have “Exhausted and Wounded and Poisoned” all working off of the same bools to walk/run and jump, but the conduit gate keeps it in and out of the right status.

You don’t have to manage a lot of rules between your main node that is talking to wounded, poisoned and exhausted all at the same time. If you do that (hook it all into your main node) it gets hit, and checks all 3+ rules every time, but with the gate it only checks 1. If you do that enough times you can save yourself from hitting a ton of rules all at the same time.

10. Frequently Asked Questions (FAQs) About Conduits

Here are some frequently asked questions about conduits:

| Question | Answer |

|---|---|

| What is the difference between conduit and raceway? | A conduit is a type of raceway, which is a general term for any enclosed channel designed to hold wires or cables. Other types of raceways include wireways, cable trays, and surface raceways. |

| Can I use PVC conduit for exposed locations? | PVC conduit is not recommended for exposed locations because it is susceptible to damage from UV radiation. Metal conduit or UV-resistant PVC conduit should be used instead. |

| How do I bend conduit without a conduit bender? | While it is possible to bend small-diameter EMT conduit by hand, it is not recommended for larger sizes or rigid conduits. Using a conduit bender ensures accurate and consistent bends without damaging the conduit. |

| What is the maximum number of wires I can run in a conduit? | The maximum number of wires allowed in a conduit is determined by electrical codes and depends on the conduit size, wire size, and wire type. Refer to the National Electrical Code (NEC) or local electrical codes for specific requirements. |

| How do I ground a metal conduit? | Metal conduits should be grounded to a grounding electrode conductor (GEC) using grounding bushings, bonding jumpers, or other approved methods. Refer to the NEC or local electrical codes for specific grounding requirements. |

| Can I use different types of conduit in the same installation? | Yes, different types of conduit can be used in the same installation, as long as they are compatible with each other and meet the requirements of the specific application and environment. |

| What is the difference between FMC and LFMC? | FMC (Flexible Metal Conduit) is a flexible steel conduit used for general-purpose applications. LFMC (Liquidtight Flexible Metal Conduit) is a flexible metal conduit with a waterproof jacket, used in wet or corrosive environments. |

| How do I choose the right conduit size? | To choose the right conduit size, calculate the total cross-sectional area of all the wires or cables that will be installed in the conduit and ensure that it does not exceed the allowable fill capacity specified in electrical codes. |

| What is the purpose of a conduit bushing? | A conduit bushing is used to protect wires from abrasion as they enter or exit a conduit. It provides a smooth, rounded surface that prevents damage to the wire insulation. |

| Where can I find more information about conduit installation and codes? | More information about conduit installation and codes can be found in the National Electrical Code (NEC), local electrical codes, and publications from organizations like the National Fire Protection Association (NFPA) and the Institute of Electrical and Electronics Engineers (IEEE). |

11. Advanced Conduit Concepts

Delving deeper into conduit systems reveals more complex aspects and considerations:

- Conduit Fill Calculations: Accurately calculating conduit fill is crucial for safety and code compliance. This involves considering wire size, insulation type, and the number of conductors within the conduit.

- Derating Factors: When multiple current-carrying conductors are installed in a conduit, the ampacity of each conductor must be derated to account for heat buildup.

- Conduit Support Spacing: Proper conduit support is essential to prevent sagging, damage, and potential hazards. Electrical codes specify maximum support spacing based on conduit size and type.

- Expansion Fittings: In long conduit runs or areas with significant temperature variations, expansion fittings are used to accommodate thermal expansion and contraction.

- Sealing Conduits: In hazardous locations, conduits must be sealed to prevent the propagation of flammable gases or vapors.

- Conduit Systems Design: Designing an efficient and code-compliant conduit system requires careful planning, consideration of load requirements, and adherence to industry best practices.

12. The Future of Conduit Technology

The field of conduit technology is constantly evolving, with new materials, designs, and installation methods emerging. Some trends to watch include:

- Smart Conduits: Conduits with integrated sensors and communication capabilities that can monitor temperature, humidity, and other environmental factors.

- Wireless Conduit Systems: Systems that eliminate the need for physical wiring by using wireless communication technology within the conduit.

- Biodegradable Conduits: Eco-friendly conduits made from sustainable materials that can decompose naturally at the end of their lifespan.

- 3D-Printed Conduits: Custom-designed conduits that can be created on-demand using 3D printing technology.

- Robotic Conduit Installation: Automated systems that use robots to install conduits quickly and efficiently.

13. Real-World Examples of Conduit Use

To further illustrate the versatility of conduits, here are some real-world examples of their application:

- Data Centers: Conduits are used to manage and protect the vast network of cables that power and connect servers in data centers.

- Hospitals: Conduits ensure the safe and reliable delivery of electricity to critical medical equipment in hospitals.

- Transportation Tunnels: Conduits protect wiring for lighting, ventilation, and communication systems in transportation tunnels.

- Wastewater Treatment Plants: Corrosion-resistant conduits are used to protect wiring from the harsh chemicals and moisture present in wastewater treatment plants.

- Renewable Energy Projects: Conduits are used to route and protect wiring for solar panels, wind turbines, and other renewable energy systems.

14. Common Mistakes to Avoid When Working With Conduits

Working with conduits requires attention to detail and adherence to safety guidelines. Here are some common mistakes to avoid:

- Using the Wrong Type of Conduit: Selecting the wrong type of conduit for a specific application can lead to premature failure, code violations, and safety hazards.

- Overtightening Fittings: Overtightening conduit fittings can damage the conduit, strip threads, and create leaks.

- Improperly Supporting Conduits: Failing to properly support conduits can cause sagging, damage, and potential hazards.

- Exceeding Conduit Fill Capacity: Exceeding the allowable fill capacity of a conduit can lead to overheating, insulation damage, and electrical fires.

- Neglecting Grounding: Neglecting to ground metal conduits properly can create a serious electrical shock hazard.

- Ignoring Code Requirements: Ignoring electrical code requirements can result in fines, rework, and safety hazards.

15. Safety Precautions When Working With Conduits

Safety should always be the top priority when working with conduits. Here are some essential safety precautions to follow:

- De-energize Circuits: Always de-energize circuits before working on electrical systems.

- Wear Personal Protective Equipment (PPE): Wear appropriate PPE, such as safety glasses, gloves, and appropriate clothing.

- Use Insulated Tools: Use insulated tools to prevent electrical shock.

- Follow Lockout/Tagout Procedures: Follow lockout/tagout procedures to prevent accidental energization of circuits.

- Work in a Well-Ventilated Area: Work in a well-ventilated area when cutting, bending, or gluing conduits.

- Inspect Tools and Equipment: Inspect tools and equipment regularly for damage or defects.

- Be Aware of Surroundings: Be aware of your surroundings and potential hazards.

- Follow Manufacturer’s Instructions: Follow the manufacturer’s instructions for all tools and equipment.

- Know Emergency Procedures: Know emergency procedures and how to respond to accidents.

16. How to Troubleshoot Common Conduit Problems

Even with proper installation and maintenance, conduit systems can sometimes experience problems. Here are some common issues and how to troubleshoot them:

- Damaged Conduit: Inspect conduits for physical damage, such as dents, cracks, or corrosion. Replace damaged sections as needed.

- Loose Fittings: Check fittings for looseness and tighten them as necessary. If fittings are corroded or damaged, replace them.

- Water Intrusion: Inspect conduits for water intrusion, especially in underground or outdoor applications. Seal any leaks and take steps to prevent future water intrusion.

- Overheating: If wires in a conduit are overheating, check for overloaded circuits, excessive conduit fill, or inadequate ventilation.

- Grounding Issues: If there are grounding issues, check the grounding connections and ensure that the conduit system is properly grounded according to code requirements.

- Code Violations: If there are code violations, correct them immediately to ensure safety and compliance.

17. Conduit Maintenance: Ensuring Longevity

Regular maintenance is essential for ensuring the longevity and reliability of conduit systems. Here are some maintenance tips:

- Visual Inspections: Conduct regular visual inspections to identify any signs of damage, corrosion, or loose fittings.

- Cleaning: Clean conduits periodically to remove dust, dirt, and other contaminants that can accelerate corrosion.

- Tightening Fittings: Tighten loose fittings to prevent leaks and ensure proper connections.

- Replacing Damaged Components: Replace damaged conduits, fittings, or supports promptly.

- Testing Grounding Systems: Test grounding systems regularly to ensure that they are functioning properly.

- Applying Protective Coatings: Apply protective coatings to metal conduits to prevent corrosion.

- Documenting Maintenance: Keep records of all maintenance activities, including inspections, repairs, and replacements.

18. Resources for Learning More About Conduits

There are numerous resources available for learning more about conduits and electrical systems:

- National Electrical Code (NEC): The NEC is the primary source of information on electrical codes and standards in the United States.

- Local Electrical Codes: Local electrical codes may have additional requirements or amendments to the NEC.

- Trade Associations: Trade associations like the National Electrical Manufacturers Association (NEMA) and the Electrical Training ALLIANCE offer training, resources, and information on electrical systems.

- Online Courses: Online courses and tutorials are available from various sources, including community colleges, trade schools, and online learning platforms.

- Books and Publications: Numerous books and publications cover electrical systems and conduit installation.

- Industry Experts: Consult with experienced electricians, engineers, and other industry experts for guidance and advice.

19. The Role of Conduits in Sustainable Building

Conduits play a vital role in sustainable building practices by:

- Protecting Energy-Efficient Wiring: Conduits protect energy-efficient wiring systems, such as LED lighting and smart home automation systems.

- Facilitating Renewable Energy Installations: Conduits are used to route and protect wiring for solar panels, wind turbines, and other renewable energy systems.

- Reducing Waste: Durable conduit systems can last for many years, reducing the need for frequent replacements and minimizing waste.

- Supporting Green Building Certifications: Proper conduit installation and maintenance can contribute to achieving green building certifications like LEED.

20. Innovative Uses of Conduits Beyond Electrical Systems

While conduits are primarily known for their use in electrical systems, they can also be used in other innovative ways:

- Plumbing Systems: Conduits can be used to protect and route plumbing pipes, especially in underground or exposed locations.

- HVAC Systems: Conduits can be used to protect and route refrigerant lines and control wiring in HVAC systems.

- Data and Communication Systems: Conduits can be used to manage and protect data and communication cables in offices, data centers, and other facilities.

- Art Installations: Conduits can be used as structural elements or decorative features in art installations.

- Furniture Design: Conduits can be incorporated into furniture designs to create unique and industrial-inspired pieces.

Have more questions about conduits or any other topic? Don’t hesitate to ask on WHAT.EDU.VN! Our community of experts is ready to provide fast, accurate, and free answers to all your questions. Located at 888 Question City Plaza, Seattle, WA 98101, United States, you can also reach us via WhatsApp at +1 (206) 555-7890. Visit what.edu.vn today and get the answers you need!