Cobalt is used for various applications across many industries. Are you eager to understand the uses of cobalt? At WHAT.EDU.VN, we provide answers to your questions for free. We explore the different applications of cobalt, highlighting its importance in enhancing material properties, energy storage, and chemical processes. Explore cobalt uses, properties, and benefits.

1. Understanding Cobalt: Properties And Characteristics

Cobalt is a chemical element with the symbol Co and atomic number 27. It is a hard, lustrous, silver-gray metal. Cobalt is a ferromagnetic metal. This means it can be magnetized, similar to iron and nickel. Cobalt’s ability to retain its strength at high temperatures makes it invaluable in applications where materials are subjected to extreme conditions.

Here are some key properties of cobalt:

- High melting point: Cobalt has a high melting point of 1,495 °C (2,723 °F).

- Excellent strength: It maintains its strength and hardness at high temperatures.

- Magnetic properties: Cobalt is a ferromagnetic material, making it useful in magnetic storage and applications.

- Corrosion resistance: Cobalt resists oxidation and corrosion, enhancing the durability of alloys.

- Catalytic activity: Cobalt compounds serve as effective catalysts in chemical reactions.

1.1. Discovering The Origins Of Cobalt

Cobalt has been used for centuries, primarily as a pigment to impart a rich blue color to glass and ceramics. The name “cobalt” comes from the German word “kobold,” meaning “goblin.” Miners gave it this name because cobalt ores were difficult to smelt and often contaminated other valuable metals.

1.2. What Makes Cobalt So Versatile?

Cobalt’s unique combination of strength, magnetic properties, and chemical stability makes it useful in many applications. Its ability to form strong alloys and act as a catalyst drives its demand across industries, from electronics to aerospace.

2. Primary Uses Of Cobalt: Where Is Cobalt Used?

Cobalt is used in numerous critical applications across various sectors. Its unique properties make it essential in batteries, alloys, magnets, and catalysts.

2.1. Cobalt In Battery Technology

Cobalt is a crucial component in lithium-ion batteries, commonly used in electric vehicles, laptops, smartphones, and other portable electronic devices.

Alt text: Lithium-ion battery components showing cobalt usage.

2.1.1. Enhancing Battery Performance

Cobalt helps stabilize the cathode, improving the battery’s energy density, lifespan, and overall performance. It prevents the cathode structure from collapsing during repeated charge and discharge cycles. This ensures the battery maintains its capacity and performs reliably over time.

2.1.2. Types Of Batteries Using Cobalt

- Lithium Cobalt Oxide (LCO): Commonly used in smartphones, tablets, and laptops due to their high energy density.

- Nickel Manganese Cobalt (NMC): Utilized in electric vehicles and power tools, balancing high energy density and safety.

- Nickel Cobalt Aluminum (NCA): Found in some electric vehicles, offering high energy density and power output.

2.2. Cobalt Alloys: Enhancing Material Properties

Cobalt is used to create high-performance alloys with exceptional strength, heat resistance, and corrosion resistance.

2.2.1. Superalloys

These alloys, containing high levels of cobalt, are used in aerospace, gas turbines, and other high-temperature applications.

- Aerospace: Cobalt-based superalloys are used in jet engines and aircraft components due to their ability to withstand extreme temperatures and stresses.

- Gas Turbines: These alloys are essential in power generation, ensuring efficient and reliable operation.

2.2.2. Hardfacing Alloys

Cobalt alloys are used as hardfacing materials to enhance the wear resistance of industrial equipment and tools.

- Mining: Components like drill bits and cutting tools are coated with cobalt alloys to prolong their lifespan and improve performance.

- Manufacturing: Machinery parts exposed to high wear benefit from cobalt hardfacing, reducing downtime and maintenance costs.

2.3. Cobalt Magnets: Creating Powerful Magnetic Fields

Cobalt is used to manufacture powerful permanent magnets that are critical in electric motors, generators, and magnetic storage devices.

2.3.1. Alnico Magnets

These magnets, made from aluminum, nickel, and cobalt, have high magnetic strength and temperature stability.

- Electric Motors: Alnico magnets are used in electric motors for automotive and industrial applications.

- Generators: They are utilized in generators to produce electricity efficiently.

2.3.2. Samarium Cobalt Magnets

Offering even higher magnetic strength and thermal stability, these magnets are used in high-performance applications.

- Aerospace: Samarium cobalt magnets are used in aerospace applications where strong, stable magnetic fields are required.

- Medical Devices: They are also used in medical devices like MRI machines, providing precise and reliable performance.

2.4. Cobalt As A Catalyst: Accelerating Chemical Reactions

Cobalt compounds act as catalysts in various chemical processes, facilitating the production of plastics, chemicals, and petroleum products.

2.4.1. Hydroformylation

Cobalt catalysts are used in hydroformylation to produce aldehydes from olefins, essential in manufacturing detergents, plasticizers, and other chemicals.

2.4.2. Oxidation Reactions

Cobalt compounds catalyze oxidation reactions in the production of terephthalic acid, a precursor to polyethylene terephthalate (PET) plastics.

2.5. Other Uses of Cobalt

Cobalt and its compounds are used for a wide array of other applications, showcasing the metal’s versatility and importance across diverse industries. These additional uses further underscore why cobalt remains a critical material in modern technology and manufacturing.

2.5.1. Pigments and Colorants

Cobalt compounds have long been used as pigments to create vibrant blue hues in ceramics, paints, and glass. Cobalt blue, known for its stability and rich color, is prized in artistic and industrial applications.

- Ceramics: Cobalt oxide is added to ceramic glazes to produce a distinctive blue finish, enhancing the aesthetic appeal of pottery and tiles.

- Paints: Cobalt-based pigments are used in paints for their lightfastness and color intensity, ensuring long-lasting and vibrant results.

- Glass: The addition of cobalt to glass imparts a deep blue color, commonly used in decorative glassware and optical filters.

2.5.2. Drying Agents

Cobalt compounds are used as drying agents in paints, varnishes, and inks. They accelerate the oxidation and polymerization of oils, leading to faster drying times and improved film hardness.

- Paints and Coatings: Cobalt driers enhance the curing process of oil-based paints, reducing tackiness and improving the overall finish quality.

- Inks: These agents ensure that inks dry quickly on printed materials, preventing smudging and enabling high-speed printing.

2.5.3. Medical Applications

Cobalt has several applications in the medical field, including radiation therapy and the production of vitamin B12.

- Radiation Therapy: Cobalt-60, a radioactive isotope of cobalt, is used in radiation therapy machines to treat cancer by delivering high-energy gamma rays to tumor sites.

- Vitamin B12: Cobalt is a key component of vitamin B12 (cobalamin), essential for red blood cell formation and neurological function.

2.5.4. Alloys for Dental Implants

Cobalt-chromium alloys are commonly used in dental implants due to their biocompatibility, strength, and corrosion resistance.

- Dental Implants: These alloys provide a stable and durable base for dental prosthetics, ensuring long-term functionality and patient comfort.

- Orthopedic Implants: Similar alloys are also used in orthopedic implants for joint replacements, offering strength and durability within the body.

2.5.5. Electroplating

Cobalt is used in electroplating processes to create hard, wear-resistant coatings on metal surfaces.

- Industrial Components: Electroplated cobalt coatings protect industrial components from wear and corrosion, extending their service life and reducing maintenance costs.

- Decorative Finishes: Cobalt electroplating is also used to create decorative finishes on metal products, enhancing their aesthetic appeal and market value.

2.5.6. Animal Feed Supplements

Cobalt is an essential micronutrient for livestock, particularly ruminants like cattle and sheep. It is added to animal feed supplements to ensure adequate vitamin B12 synthesis in the rumen.

- Livestock Nutrition: Cobalt supplementation prevents deficiencies that can lead to anemia and poor growth in animals, supporting overall herd health and productivity.

2.5.7. Magnetic Recording Media

Cobalt alloys are used in magnetic recording media, such as hard disk drives and magnetic tapes, to store digital information.

- Hard Disk Drives (HDDs): Cobalt-based alloys enable high-density data storage in HDDs, supporting the growing demand for digital storage capacity.

- Magnetic Tapes: These alloys are used in magnetic tapes for archival storage, providing a reliable and long-lasting medium for preserving valuable data.

Alt text: Image of Cobalt Mines in the Democratic Republic of Congo.

3. The Cobalt Supply Chain: From Mining To Manufacturing

Cobalt’s journey from raw ore to finished product involves a complex global supply chain. Most of the world’s cobalt comes from the Democratic Republic of Congo (DRC). Mining accounts for 90% of the country’s exports, and has vital source of income.

3.1. Mining and Extraction

Cobalt is primarily mined as a byproduct of copper and nickel extraction. The DRC accounts for over 70% of global cobalt production.

3.2. Processing and Refining

The extracted ore is processed to separate cobalt from other metals. Refined cobalt is produced in various forms, including powders, briquettes, and salts.

3.3. Manufacturing and Application

Refined cobalt is used in manufacturing batteries, alloys, magnets, and catalysts. These products are then integrated into various industries, including automotive, electronics, and aerospace.

4. Environmental And Ethical Considerations

Cobalt mining is associated with significant environmental and ethical concerns, particularly in the DRC, where artisanal mining practices are common.

4.1. Environmental Impact

Mining activities can lead to deforestation, soil erosion, and water pollution, disrupting local ecosystems.

4.2. Human Rights Issues

Artisanal mining often involves child labor, unsafe working conditions, and human rights abuses. Miners face risks of injury, respiratory problems, and long-term health issues.

4.3. Sustainable Sourcing Initiatives

Efforts are underway to promote responsible cobalt sourcing through supply chain transparency, ethical mining practices, and support for local communities. Initiatives such as the Cobalt Institute and the Responsible Minerals Initiative aim to address these challenges.

5. Cobalt and Electric Vehicles: Driving the Future of Transportation

Cobalt plays a crucial role in the electric vehicle (EV) industry. EVs are essential for reducing carbon emissions and combating climate change. Cobalt is a key component in the lithium-ion batteries that power EVs. It helps improve battery performance, stability, and longevity.

5.1. Cobalt’s Impact on EV Battery Technology

Cobalt is primarily used in the cathode of lithium-ion batteries, where it enhances the battery’s energy density and thermal stability. This is particularly important for EVs. High energy density allows EVs to travel longer distances on a single charge, while thermal stability ensures the battery operates safely and efficiently under various conditions.

5.2. Different Types of EV Batteries Using Cobalt

Several types of lithium-ion batteries used in EVs rely on cobalt. These include:

- Nickel-Cobalt-Aluminum (NCA) Batteries: These batteries offer high energy density and are commonly used in Tesla vehicles.

- Nickel-Manganese-Cobalt (NMC) Batteries: NMC batteries balance energy density, thermal stability, and cost, making them popular in a wide range of EVs from different manufacturers.

5.3. The Push for Cobalt-Free Batteries

Due to ethical and environmental concerns associated with cobalt mining, there’s a growing push to develop cobalt-free batteries. One promising alternative is Lithium Iron Phosphate (LFP) batteries. These batteries don’t require cobalt and offer good thermal stability and a longer lifespan. However, they generally have lower energy density compared to cobalt-based batteries. This may limit the range of EVs.

5.4. The Future of Cobalt in EVs

Despite the development of cobalt-free alternatives, cobalt is likely to remain an important material in EV batteries for the foreseeable future. Researchers are working on reducing the amount of cobalt needed in batteries while maintaining high performance levels. Additionally, efforts to improve the sustainability and ethics of cobalt mining are essential for ensuring a responsible supply chain for the EV industry.

5.5. Cobalt Recycling in EVs

Recycling cobalt from end-of-life EV batteries is another critical aspect of ensuring a sustainable supply chain. Recycling can reduce the demand for newly mined cobalt. It can also minimize the environmental impact associated with mining activities. As the EV market grows, developing efficient and cost-effective cobalt recycling processes will become increasingly important.

5.6. Cobalt and Battery Innovation

Cobalt is also driving innovation in battery technology. Researchers are exploring new battery chemistries that incorporate cobalt. They are improving energy density, charging speed, and overall performance. These advancements will help enhance the capabilities of EVs. They will make them more competitive with traditional gasoline-powered vehicles.

6. Addressing Ethical Concerns in the Cobalt Industry

The cobalt industry faces significant ethical challenges. These mainly revolve around human rights abuses and unsafe working conditions in mining operations. Efforts to address these concerns are vital for creating a more responsible and sustainable cobalt supply chain.

6.1. Human Rights Abuses in Cobalt Mining

One of the primary ethical concerns in the cobalt industry is the prevalence of human rights abuses in artisanal and small-scale mining (ASM) operations. In countries like the Democratic Republic of Congo (DRC), where a significant portion of the world’s cobalt is mined, ASM operations often involve child labor, forced labor, and hazardous working conditions. Miners work long hours with little to no safety equipment. They face the constant risk of injury or death due to mine collapses and other accidents.

6.2. Initiatives for Responsible Cobalt Sourcing

Several initiatives aim to promote responsible cobalt sourcing and address human rights abuses in the industry. These include:

- The Cobalt Institute: This organization promotes the responsible and sustainable production and use of cobalt. They provide a platform for stakeholders to collaborate and address ethical and environmental challenges.

- The Responsible Minerals Initiative (RMI): RMI offers tools and resources for companies to conduct due diligence on their mineral supply chains. They help ensure they are not contributing to human rights abuses or conflict.

- The Fair Cobalt Alliance (FCA): FCA works to improve the livelihoods of artisanal mining communities in the DRC by promoting fair labor practices and providing access to education and healthcare.

6.3. Supply Chain Transparency and Traceability

Increasing supply chain transparency and traceability is essential for addressing ethical concerns in the cobalt industry. Companies must be able to trace the cobalt they use back to its source. They must ensure it was mined in a responsible and ethical manner. Technologies like blockchain can help enhance supply chain transparency. They make it easier to track the movement of cobalt from the mine to the end product.

6.4. Due Diligence and Risk Assessments

Companies sourcing cobalt must conduct thorough due diligence and risk assessments to identify and mitigate potential ethical and environmental risks in their supply chains. This involves assessing mining operations, labor practices, and environmental impacts. It also involves working with suppliers to implement corrective action plans where necessary.

6.5. Collaboration and Partnerships

Addressing ethical concerns in the cobalt industry requires collaboration and partnerships between governments, industry stakeholders, NGOs, and local communities. By working together, these stakeholders can develop and implement effective solutions for promoting responsible cobalt sourcing and improving the lives of miners and their families.

6.6. Consumer Awareness and Advocacy

Raising consumer awareness about the ethical challenges in the cobalt industry is also important. Consumers can make informed purchasing decisions and support companies that are committed to responsible cobalt sourcing. Advocacy groups play a crucial role in holding companies accountable and advocating for policies that promote ethical mining practices.

7. Cobalt Recycling: Creating a Circular Economy

Cobalt recycling is a critical aspect of creating a sustainable and responsible cobalt supply chain. By recycling cobalt from end-of-life products, we can reduce the demand for newly mined cobalt. We can also minimize the environmental and social impacts associated with mining activities.

7.1. Benefits of Cobalt Recycling

Recycling cobalt offers several key benefits:

- Resource Conservation: Recycling reduces the need to extract new cobalt from the earth. This conserves natural resources and reduces the environmental impact of mining.

- Energy Savings: Recycling cobalt requires less energy than mining and processing new cobalt. This reduces greenhouse gas emissions and helps combat climate change.

- Waste Reduction: Recycling diverts end-of-life products from landfills. This reduces pollution and conserves landfill space.

- Ethical Sourcing: Recycling can help reduce the reliance on cobalt mined in regions with ethical concerns. It promotes a more responsible and sustainable supply chain.

7.2. Sources of Recycled Cobalt

Cobalt can be recycled from various sources, including:

- Lithium-ion Batteries: Batteries from electric vehicles, laptops, smartphones, and other electronic devices are a significant source of recycled cobalt.

- Superalloys: Cobalt-containing superalloys used in aerospace and industrial applications can be recycled to recover valuable cobalt.

- Spent Catalysts: Cobalt catalysts used in chemical processes can be recycled to recover cobalt and other valuable metals.

- Industrial Scrap: Scrap metal from manufacturing processes that contain cobalt can be recycled to recover cobalt.

7.3. Cobalt Recycling Technologies

Several technologies are used to recycle cobalt from end-of-life products. These include:

- Hydrometallurgy: This involves using chemical solutions to dissolve cobalt and other metals from the waste material. The metals are then selectively recovered from the solution using techniques like solvent extraction and electrowinning.

- Pyrometallurgy: This involves using high temperatures to melt the waste material and separate the cobalt from other metals. The molten metals are then further refined to produce pure cobalt.

- Direct Recycling: This involves directly reusing or repurposing cobalt-containing components without breaking them down into their constituent elements. For example, entire battery packs from electric vehicles can be repurposed for energy storage applications.

7.4. Challenges in Cobalt Recycling

Despite the benefits of cobalt recycling, several challenges need to be addressed:

- Collection and Sorting: Collecting and sorting end-of-life products containing cobalt can be complex. Proper infrastructure and logistics are needed to ensure efficient collection and sorting.

- Recycling Costs: Recycling cobalt can be more expensive than mining new cobalt. This can make it difficult for recycled cobalt to compete with newly mined cobalt in the market.

- Technology Development: Further research and development are needed to improve the efficiency and cost-effectiveness of cobalt recycling technologies.

- Regulations and Standards: Clear regulations and standards are needed to ensure that cobalt recycling is conducted in an environmentally sound and socially responsible manner.

7.5. The Future of Cobalt Recycling

Cobalt recycling is expected to play an increasingly important role in the future of the cobalt industry. As the demand for cobalt continues to grow, recycling will become essential for ensuring a sustainable and responsible supply chain. Governments, industry stakeholders, and researchers must collaborate to address the challenges in cobalt recycling and promote the development of a circular economy for cobalt.

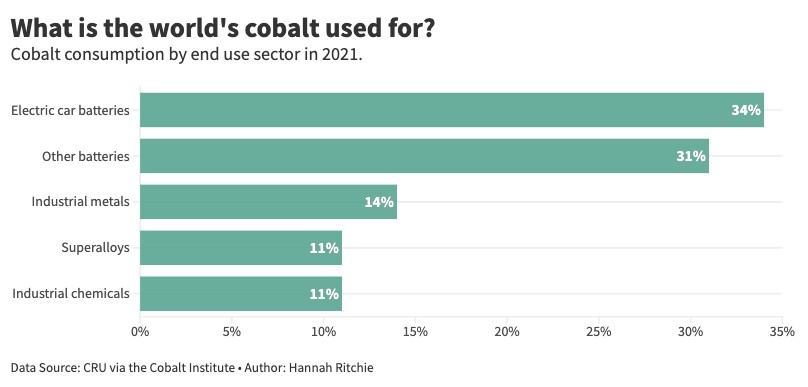

EVs were the biggest user, consuming just over one-third. Batteries for other consumer products were not far behind at 31%.

EVs were the biggest user, consuming just over one-third. Batteries for other consumer products were not far behind at 31%.

Alt text: A bar chart depicting cobalt usage in different applications.

8. Innovations And Future Trends In Cobalt Use

Ongoing research and development efforts are exploring new applications and technologies to enhance the use of cobalt.

8.1. Reducing Cobalt Content In Batteries

Researchers are developing battery chemistries that reduce or eliminate the need for cobalt, such as lithium iron phosphate (LFP) and sodium-ion batteries.

8.2. Advanced Alloys

New cobalt alloys are being developed for applications requiring extreme strength, temperature resistance, and corrosion resistance.

8.3. Nanomaterials

Cobalt nanomaterials are being explored for applications in catalysis, energy storage, and biomedical engineering.

9. Cobalt: Frequently Asked Questions (FAQ)

| Question | Answer |

|---|---|

| What are the main uses of cobalt? | Cobalt is used in batteries, superalloys, magnets, catalysts, pigments, and medical applications. |

| Why is cobalt important in batteries? | Cobalt stabilizes the cathode in lithium-ion batteries, improving energy density, lifespan, and safety. |

| What are the environmental concerns related to cobalt mining? | Cobalt mining can lead to deforestation, soil erosion, water pollution, and human rights abuses, particularly in artisanal mines. |

| What is being done to address ethical issues in cobalt mining? | Initiatives like the Cobalt Institute and Responsible Minerals Initiative promote responsible sourcing, supply chain transparency, and ethical mining practices. |

| What are some alternatives to cobalt in batteries? | Lithium iron phosphate (LFP) and sodium-ion batteries are being developed as cobalt-free alternatives, offering potential benefits in cost and sustainability. |

| How is cobalt recycled, and why is it important? | Cobalt is recycled from batteries, superalloys, and industrial scrap using hydrometallurgical and pyrometallurgical processes. Recycling reduces the need for new mining and minimizes environmental impact. |

| What are superalloys, and how is cobalt used in them? | Superalloys are high-performance alloys used in extreme conditions. Cobalt enhances their strength, heat resistance, and corrosion resistance. |

| What role does cobalt play in the medical field? | Cobalt-60 is used in radiation therapy to treat cancer, and cobalt is a key component of vitamin B12, essential for red blood cell formation and neurological function. |

| How can consumers support responsible cobalt sourcing? | Consumers can support companies that are committed to responsible cobalt sourcing, look for certifications, and stay informed about the ethical challenges in the cobalt industry. |

| What are the future trends in cobalt use? | Future trends include reducing cobalt content in batteries, developing advanced alloys, and exploring cobalt nanomaterials for various applications. |

| What is the significance of cobalt in electroplating? | Cobalt is used in electroplating to create hard, wear-resistant coatings on metal surfaces, enhancing durability and corrosion protection in industrial components and decorative finishes. |

| How does cobalt contribute to animal nutrition? | Cobalt is an essential micronutrient for livestock, particularly ruminants, as it is a key component of vitamin B12, which is crucial for red blood cell formation and overall health. |

| In what ways is cobalt used in magnetic recording media? | Cobalt alloys are used in hard disk drives and magnetic tapes for high-density data storage, enabling the preservation and accessibility of digital information. |

| What is the role of cobalt in hydroformylation? | Cobalt catalysts are used in hydroformylation to produce aldehydes from olefins, which are essential in manufacturing detergents, plasticizers, and other chemicals. |

| How does cobalt contribute to the production of PET plastics? | Cobalt compounds catalyze oxidation reactions in the production of terephthalic acid, a precursor to polyethylene terephthalate (PET) plastics, which are widely used in packaging and various consumer products. |

10. Conclusion: The Enduring Importance Of Cobalt

Cobalt’s unique properties make it indispensable in a variety of critical applications. From powering electric vehicles to enhancing the durability of industrial equipment, cobalt plays a vital role in modern technology. Addressing the environmental and ethical challenges associated with its mining is crucial for ensuring a sustainable and responsible supply chain. With ongoing innovations and a commitment to responsible sourcing, cobalt will continue to be a key material for the foreseeable future.

Do you have more questions about cobalt or any other topic? Don’t hesitate to ask WHAT.EDU.VN. Our community of experts is here to provide you with accurate and helpful answers, completely free of charge. Contact us at 888 Question City Plaza, Seattle, WA 98101, United States. Whatsapp: +1 (206) 555-7890. Visit our website what.edu.vn today and ask away.