DTF printing, also known as Direct to Film printing, is revolutionizing the textile and apparel industry. Uncover the advantages, process, and equipment you need for DTF printing at WHAT.EDU.VN. This comprehensive guide simplifies the complexities and provides solutions for all your printing needs with insightful tips and free answers to your queries. Explore DTF transfers, DTF printers, and DTF inks.

1. Understanding DTF Printing: A Comprehensive Overview

Direct to Film (DTF) printing is a revolutionary method in the world of garment decoration. Unlike traditional methods, DTF involves printing your designs directly onto a special film and then transferring that print onto a variety of fabrics, including cotton, polyester, and blends. This versatility makes it a popular choice for businesses of all sizes. The process is particularly effective because it can handle white ink, enabling vibrant prints on dark-colored garments. DTF printing is known for its flexibility, cost-effectiveness, and ability to produce high-quality, durable prints.

1.1. Defining Direct to Film (DTF) Printing

DTF printing stands for Direct to Film printing. It is a digital printing technology where designs are printed onto a special film, which is then transferred onto fabrics using heat and pressure. This method is suitable for various materials, including cotton, polyester, and their blends, making it a versatile option for customizing apparel and other textile products.

1.2. The DTF Printing Process: A Step-by-Step Guide

The DTF printing process involves several key steps, each critical to achieving a high-quality final product:

- Design Preparation: Begin with a digital design, ensuring it’s high-resolution for the best print quality.

- Printing on Film: The design is printed onto a special DTF film using a DTF printer with textile inks. A crucial aspect is the simultaneous printing of white ink as an underbase for colored inks.

- Powder Application: After printing, DTF powder is applied to the wet ink on the film. This powder acts as an adhesive, bonding the ink to the fabric during heat pressing.

- Curing the Film: The powdered film is then cured using a heat press or a curing oven, melting the adhesive powder and ensuring it adheres properly to the ink.

- Heat Transfer to Fabric: The final step involves heat pressing the film onto the fabric. The heat and pressure transfer the design from the film to the fabric, creating a durable and vibrant print.

- Peeling the Film: Once cooled, the film is peeled away, leaving the design permanently adhered to the fabric.

1.3. Key Advantages of DTF Printing

DTF printing offers several advantages over traditional printing methods:

- Versatility: Works on a wide range of fabrics, including cotton, polyester, and blends.

- Vibrant Colors: Ability to print white ink allows for bright and vivid designs on dark fabrics.

- Durability: Prints are highly resistant to washing and wear, ensuring longevity.

- Cost-Effective: Lower startup costs compared to other digital printing methods like DTG.

- Ease of Use: Relatively simple process, making it accessible for small businesses and startups.

- No Pre-treatment Required: Unlike DTG, DTF doesn’t require pre-treating garments, saving time and resources.

1.4. Common Applications of DTF Printing

DTF printing is utilized across various applications, including:

- Custom Apparel: T-shirts, hoodies, sweatshirts, and other clothing items.

- Promotional Products: Bags, hats, and other promotional items.

- Home Textiles: Cushion covers, curtains, and other home décor items.

- Fashion Industry: Customized designs for clothing lines and fashion brands.

- Small Businesses: Ideal for small-scale customization and personalized gifts.

1.5. Why DTF Printing is Gaining Popularity

The rising popularity of DTF printing can be attributed to its numerous benefits. Its versatility allows businesses to cater to a wide range of customer needs, while its cost-effectiveness makes it accessible for startups and small businesses. The durability and vibrant colors of DTF prints ensure customer satisfaction, and the ease of use simplifies the production process.

2. Essential Equipment for DTF Printing

Setting up a DTF printing operation requires specific equipment to ensure high-quality results. This section outlines the necessary tools and machinery, along with cost considerations and recommendations for choosing the right equipment.

2.1. Core Components of a DTF Printing Setup

- Modified Inkjet Printer: Essential for DTF printing, these printers are typically modified to handle DTF inks and films.

- DTF Inks: Specially formulated inks that provide elasticity and durability, preventing cracking when the fabric is stretched.

- DTF Film: The medium onto which designs are printed. It is designed to release the ink onto the fabric during heat pressing.

- DTF Powder: An adhesive powder that bonds the ink to the fabric, ensuring a strong and lasting connection.

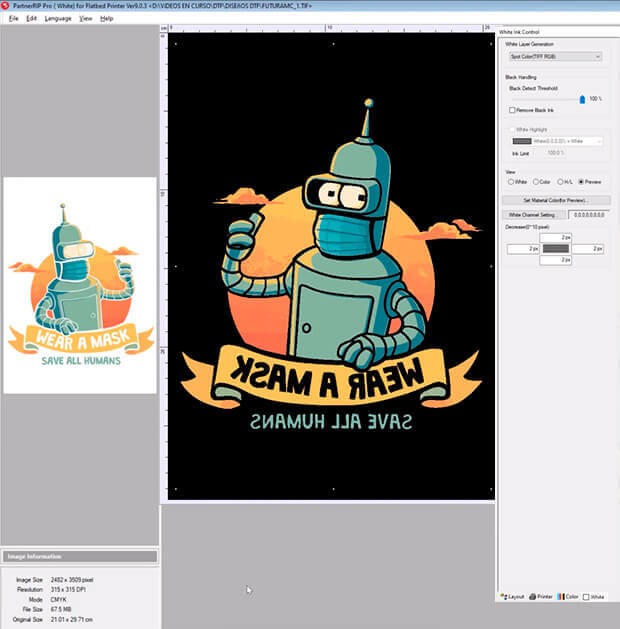

- RIP Software: Software that manages the printing process, ensuring correct color output and white ink layering.

- Heat Press: Used to transfer the design from the film to the fabric with heat and pressure.

2.2. Detailed Breakdown of Essential Equipment

2.2.1. DTF Printer

A modified inkjet printer is the heart of the DTF printing system. These printers are adapted to handle DTF inks and films, providing the necessary precision and control for high-quality prints.

2.2.2. DTF Inks

DTF inks are specially formulated to offer elasticity and durability. These inks prevent cracking when the fabric is stretched, ensuring the longevity of the print.

2.2.3. DTF Film

DTF film is the medium onto which designs are printed. It is designed to release the ink onto the fabric during the heat pressing process, ensuring a clean and accurate transfer.

2.2.4. DTF Powder

DTF powder acts as an adhesive, bonding the ink to the fabric. This powder ensures a strong and lasting connection, making the print durable and resistant to washing and wear.

2.2.5. RIP Software

RIP (Raster Image Processor) software is crucial for managing the printing process. It ensures correct color output and manages the layering of white ink, which is essential for printing on dark fabrics.

2.2.6. Heat Press

A heat press is used to transfer the design from the film to the fabric. It applies heat and pressure, ensuring the ink adheres properly to the fabric for a lasting print.

2.3. Cost Considerations for DTF Equipment

The cost of DTF equipment can vary widely depending on the quality and features of each component. A basic setup, including a modified printer, inks, film, powder, RIP software, and heat press, can range from $1,500 to $5,000. Higher-end equipment with advanced features can cost significantly more.

2.4. Choosing the Right DTF Printer

Selecting the right DTF printer involves considering factors such as print volume, print quality, and budget. Researching different models and reading reviews can help you make an informed decision. Also, consider the printer’s compatibility with different types of DTF inks and films.

2.5. Selecting Quality DTF Inks and Films

The quality of DTF inks and films directly impacts the final print. Opt for reputable brands known for their vibrant colors, durability, and compatibility with your printer. High-quality inks and films ensure that your prints are both visually appealing and long-lasting.

2.6. Maintaining Your DTF Printing Equipment

Regular maintenance is crucial for prolonging the life of your DTF printing equipment and ensuring consistent print quality. This includes cleaning the printer heads, monitoring ink levels, and properly storing inks and films.

3. DTF Printing vs. Other Printing Methods

DTF printing is just one of many methods available for garment decoration. Understanding the differences between DTF and other popular techniques, such as DTG (Direct to Garment) and white toner printing, can help you choose the best option for your specific needs.

3.1. DTF vs. DTG Printing: A Detailed Comparison

Both DTF and DTG printing use inkjet technology, but they differ significantly in their processes and applications. Here’s a detailed comparison:

3.1.1. Investment Costs

DTF printing generally requires a lower initial investment compared to DTG. A complete DTF setup can cost significantly less than a DTG printer, making it a more accessible option for startups and small businesses.

3.1.2. Production Time

DTG printing typically has a faster production time since it prints directly onto the garment. DTF printing involves printing on film, applying powder, curing, and then heat pressing, which adds extra steps to the process.

3.1.3. Print Quality and Finish

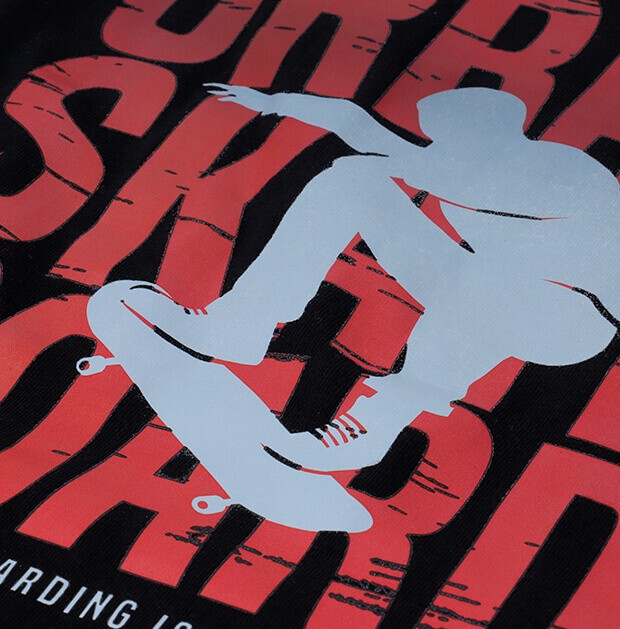

DTG prints have a softer feel because the ink is directly absorbed into the fabric. DTF prints have a slightly plasticized feel, similar to screen prints or heat transfer vinyl.

3.1.4. White Ink Intensity

DTG printing generally produces a purer and more intense white compared to DTF. However, advancements in DTF ink technology are continually improving white ink vibrancy.

3.1.5. Fabric Compatibility

DTF printing is more versatile in terms of fabric compatibility. It can be used on cotton, polyester, and blends, while DTG is best suited for cotton fabrics.

3.1.6. Consumable Costs

Both methods have relatively low consumable costs, but DTF may have slightly higher supply costs due to the use of film and powder.

3.2. DTF vs. White Toner Printing: Key Differences

White toner printing involves using a laser printer with white toner to print designs that can be transferred to garments. Here’s how DTF compares:

3.2.1. Investment Costs

DTF printing is typically more cost-effective than white toner printing. DTF kits are generally less expensive than laser printers and the associated transfer papers.

3.2.2. Printing Process

DTF printing is simpler than white toner printing. DTF prints the white layer simultaneously with the color layer, while white toner printing may require additional steps to add the adhesive and weed the transfer.

3.2.3. Print Quality and Durability

DTF prints offer excellent elasticity and wear resistance due to the use of textile inks. White toner prints can be less durable and may crack over time.

3.2.4. Consumable Costs

DTF printing has lower consumable costs compared to white toner printing. White toner printing requires specialized transfer papers, which can be expensive.

3.2.5. Versatility

White toner printing can be used on a wider range of materials, including rigid objects, while DTF is primarily used for textiles.

3.3. Other Printing Methods

- Screen Printing: A traditional method that uses stencils to apply ink onto fabric. It is cost-effective for large quantities but requires significant setup time and costs.

- Sublimation: A process that transfers dye onto synthetic fabrics using heat. It is ideal for polyester fabrics but not suitable for cotton or dark-colored materials.

- Heat Transfer Vinyl (HTV): A method that uses a vinyl cutter to create designs that are then heat-pressed onto fabric. It is suitable for small quantities and simple designs but can be time-consuming for complex graphics.

3.4. Factors to Consider When Choosing a Printing Method

When selecting a printing method, consider the following factors:

- Budget: How much are you willing to invest in equipment and supplies?

- Production Volume: How many items do you need to print?

- Fabric Type: What types of fabrics will you be printing on?

- Print Quality: What level of detail and durability do you require?

- Ease of Use: How easy is the process to learn and operate?

- Application: What types of products will you be creating?

4. Pros and Cons of DTF Printing

Like any printing method, DTF has its advantages and disadvantages. Understanding these can help you determine if DTF printing is the right choice for your business or project.

4.1. Advantages of DTF Printing

- Low Investment: DTF printing requires a relatively low initial investment, making it accessible for small businesses and startups.

- Versatility: DTF can be used on a wide range of fabrics, including cotton, polyester, and blends.

- Vibrant Colors: The ability to print white ink allows for bright and vivid designs on dark fabrics.

- Durability: DTF prints are highly resistant to washing and wear, ensuring longevity.

- No Pre-treatment Required: Unlike DTG, DTF doesn’t require pre-treating garments, saving time and resources.

- Suitable for Small Orders: DTF is cost-effective for small and medium-sized orders, making it ideal for personalized items.

4.2. Disadvantages of DTF Printing

- Print Feel: DTF prints can have a slightly plasticized feel compared to DTG prints, which have a softer touch.

- Multi-Step Process: The DTF process involves several steps, including printing on film, applying powder, curing, and heat pressing, which can be more time-consuming than other methods.

- Equipment Maintenance: DTF printers require regular maintenance to ensure optimal performance and print quality.

- Color Matching: Achieving precise color matching can be challenging, requiring careful calibration of the printer and RIP software.

- Ventilation: DTF printing can produce fumes, so proper ventilation is necessary to ensure a safe working environment.

4.3. Addressing the Disadvantages

While DTF printing has some drawbacks, many of these can be mitigated with the right techniques and equipment:

- Print Feel: Using high-quality inks and fine powders can reduce the plasticized feel of DTF prints.

- Multi-Step Process: Streamlining the printing process and investing in efficient equipment can help reduce production time.

- Equipment Maintenance: Implementing a regular maintenance schedule and using quality cleaning supplies can prolong the life of your equipment.

- Color Matching: Calibrating your printer and using color management tools in your RIP software can improve color accuracy.

- Ventilation: Installing a ventilation system or working in a well-ventilated area can reduce exposure to fumes.

4.4. Common Challenges in DTF Printing

- Ink Clogging: DTF inks can clog printer heads if not properly maintained. Regular cleaning and flushing of the print heads can prevent this issue.

- Powder Adhesion: Ensuring even adhesion of DTF powder to the ink is crucial for a successful transfer. Using a powder shaker or applying the powder manually can help.

- Film Release: The film must release cleanly from the fabric after heat pressing. Using the correct heat and pressure settings and allowing the print to cool before peeling can help prevent issues.

- Color Bleeding: Color bleeding can occur if the ink is not properly cured or if the heat press settings are incorrect. Adjusting the temperature and pressure settings and ensuring proper curing can prevent this.

4.5. Tips for Overcoming DTF Printing Challenges

- Regular Maintenance: Clean your printer heads regularly and follow the manufacturer’s recommendations for maintenance.

- Proper Powder Application: Use a powder shaker or apply the powder manually to ensure even coverage.

- Correct Heat Press Settings: Use the recommended heat and pressure settings for the fabric and ink you are using.

- Proper Curing: Ensure the ink is fully cured before heat pressing to prevent color bleeding and ensure durability.

- Ventilation: Work in a well-ventilated area or install a ventilation system to reduce exposure to fumes.

5. Step-by-Step Guide to DTF Printing

This section provides a detailed, step-by-step guide to DTF printing, covering everything from design preparation to the final heat-pressing process.

5.1. Preparing Your Design

- Choose a Design: Select a high-resolution design that is suitable for printing.

- Adjust Colors: Adjust the colors in your design to ensure they are vibrant and accurate.

- Create a White Underbase: If printing on dark fabrics, create a white underbase layer to ensure the colors stand out.

- Save the File: Save the design in a compatible format, such as PNG or TIFF.

5.2. Printing on DTF Film

- Load the Film: Load the DTF film into the printer, ensuring it is properly aligned.

- Adjust Printer Settings: Adjust the printer settings to match the type of film and ink you are using.

- Print the Design: Print the design onto the DTF film, ensuring the white underbase layer is printed first.

5.3. Applying DTF Powder

- Apply Powder: Evenly apply DTF powder to the printed design while the ink is still wet.

- Remove Excess Powder: Remove any excess powder by gently shaking the film or using a brush.

5.4. Curing the Film

- Place the Film in a Curing Oven: Place the powdered film in a curing oven at the recommended temperature and time.

- Cure the Powder: Cure the powder until it is melted and the surface is smooth.

5.5. Heat Pressing the Design

- Prepare the Fabric: Place the fabric on the heat press, ensuring it is flat and smooth.

- Position the Film: Position the cured film on the fabric, with the design facing down.

- Heat Press: Heat press the design onto the fabric at the recommended temperature and pressure for the specified time.

- Peel the Film: Allow the fabric to cool, then carefully peel the film away from the fabric.

5.6. Post-Processing Steps

- Inspect the Print: Inspect the print for any flaws or imperfections.

- Wash the Garment: Wash the garment inside out in cold water to ensure the print is durable.

- Dry the Garment: Dry the garment on low heat or hang it to dry.

5.7. Troubleshooting Common Issues

- Ink Clogging: Clean the printer heads and use high-quality inks.

- Powder Adhesion: Ensure even powder application and use a powder shaker.

- Film Release: Use the correct heat press settings and allow the fabric to cool before peeling.

- Color Bleeding: Ensure proper curing and use high-quality inks.

6. Optimizing DTF Prints for Durability and Quality

Creating durable and high-quality DTF prints requires attention to detail and the right techniques. This section outlines best practices for ensuring your prints look great and last long.

6.1. Selecting the Right Fabrics

- Cotton: DTF works well on cotton, producing vibrant and durable prints.

- Polyester: DTF is also suitable for polyester, offering excellent color fastness and durability.

- Blends: DTF can be used on blends of cotton and polyester, providing a good balance of comfort and durability.

- Other Fabrics: DTF can also be used on other fabrics, such as nylon and canvas, but testing is recommended to ensure optimal results.

6.2. Choosing High-Quality Inks and Films

- Inks: Use high-quality DTF inks that are specifically formulated for textile printing. These inks offer vibrant colors, excellent durability, and good wash resistance.

- Films: Choose DTF films that are designed for optimal ink transfer and easy peeling. These films ensure a clean and accurate transfer of the design onto the fabric.

6.3. Proper Curing Techniques

- Curing Time: Follow the manufacturer’s recommendations for curing time and temperature.

- Curing Temperature: Use the correct curing temperature to ensure the powder is properly melted and bonded to the ink.

- Curing Equipment: Use a curing oven or heat press to cure the powder evenly and consistently.

6.4. Heat Press Settings

- Temperature: Use the recommended temperature for the fabric and ink you are using.

- Pressure: Apply the correct pressure to ensure the design is properly transferred to the fabric.

- Time: Heat press the design for the specified time to ensure a durable and long-lasting print.

6.5. Washing and Care Instructions

- Wash Inside Out: Wash garments inside out to protect the print from abrasion.

- Cold Water: Wash garments in cold water to prevent color fading and shrinkage.

- Gentle Cycle: Use a gentle cycle to minimize wear and tear on the print.

- Low Heat Drying: Dry garments on low heat or hang them to dry to prevent damage to the print.

- Avoid Bleach: Avoid using bleach or harsh detergents, as they can damage the print.

6.6. Testing and Quality Control

- Wash Tests: Perform wash tests to ensure the print is durable and resistant to fading.

- Stretch Tests: Perform stretch tests to ensure the print does not crack or peel when the fabric is stretched.

- Visual Inspection: Visually inspect the print for any flaws or imperfections.

7. DTF Printing Business Opportunities

DTF printing opens up a wide range of business opportunities, from custom apparel to promotional products. This section explores some of the most promising avenues for entrepreneurs looking to enter the DTF printing market.

7.1. Custom Apparel Printing

- T-shirts: Offer custom-printed T-shirts for individuals, teams, and organizations.

- Hoodies: Provide custom-printed hoodies for schools, sports teams, and businesses.

- Sweatshirts: Offer custom-printed sweatshirts for events, promotions, and everyday wear.

- Other Apparel: Customize other apparel items, such as leggings, tank tops, and jackets, to cater to a wide range of customer needs.

7.2. Promotional Products

- Bags: Offer custom-printed bags for events, promotions, and retail sales.

- Hats: Provide custom-printed hats for sports teams, businesses, and promotional giveaways.

- Other Promotional Items: Customize other promotional items, such as mugs, keychains, and phone cases, to help businesses promote their brand.

7.3. Personalized Gifts

- Custom Mugs: Offer custom-printed mugs for birthdays, holidays, and special occasions.

- Personalized Phone Cases: Provide personalized phone cases with photos, designs, and text.

- Custom Home Decor: Offer custom-printed home decor items, such as cushion covers, curtains, and wall art.

7.4. Niche Markets

- Sports Teams: Offer custom-printed apparel and merchandise for local sports teams.

- Schools: Provide custom-printed apparel for schools, clubs, and events.

- Businesses: Offer custom-printed apparel and promotional products for businesses.

- Events: Provide custom-printed apparel and merchandise for events, such as concerts, festivals, and conferences.

7.5. Online Sales

- E-commerce Store: Create an e-commerce store to sell custom-printed products online.

- Print-on-Demand: Partner with a print-on-demand service to fulfill orders without holding inventory.

- Social Media Marketing: Use social media to promote your products and reach a wider audience.

7.6. Local Partnerships

- Local Businesses: Partner with local businesses to provide custom-printed apparel and promotional products.

- Schools: Partner with local schools to provide custom-printed apparel for students and staff.

- Sports Teams: Partner with local sports teams to provide custom-printed apparel and merchandise.

8. Future Trends in DTF Printing

The DTF printing industry is constantly evolving, with new technologies and trends emerging all the time. Staying informed about these developments can help you stay ahead of the competition and maximize your business potential.

8.1. Advancements in Ink Technology

- Improved Durability: Inks are becoming more durable and resistant to washing and wear.

- Enhanced Color Gamut: New inks offer a wider color gamut, allowing for more vibrant and accurate prints.

- Eco-Friendly Options: Eco-friendly inks are becoming more widely available, offering a sustainable alternative to traditional inks.

8.2. Automation and Efficiency

- Automated Powder Application: Automated powder application systems are streamlining the DTF printing process, reducing labor costs and improving efficiency.

- Faster Curing Times: New curing technologies are reducing curing times, allowing for faster production speeds.

- Integrated Systems: Integrated DTF printing systems are combining multiple steps into a single machine, further streamlining the printing process.

8.3. Expanding Applications

- New Fabrics: DTF printing is being used on an increasingly wide range of fabrics, including leather, denim, and other specialty materials.

- 3D Printing: DTF printing is being combined with 3D printing to create unique and innovative products.

- Textile Embellishments: DTF printing is being used to create intricate textile embellishments, such as sequins, beads, and embroidery.

8.4. Sustainable Practices

- Eco-Friendly Inks: The use of eco-friendly inks is becoming more widespread, reducing the environmental impact of DTF printing.

- Waste Reduction: DTF printing is becoming more efficient, reducing waste and minimizing the use of resources.

- Recycling Programs: Recycling programs are being implemented to recycle DTF films and other waste materials.

8.5. Personalization and Customization

- Mass Customization: DTF printing is enabling mass customization, allowing consumers to create personalized products on a large scale.

- On-Demand Printing: DTF printing is facilitating on-demand printing, allowing businesses to fulfill orders quickly and efficiently.

- Interactive Designs: DTF printing is being used to create interactive designs that respond to touch, light, or other stimuli.

8.6. Integration with E-Commerce

- Seamless Integration: DTF printing is being seamlessly integrated with e-commerce platforms, allowing businesses to easily sell custom-printed products online.

- Real-Time Design Tools: Real-time design tools are being integrated into e-commerce websites, allowing customers to create personalized designs in real-time.

- Automated Order Fulfillment: Automated order fulfillment systems are streamlining the process of fulfilling online orders for custom-printed products.

9. Frequently Asked Questions (FAQs) About DTF Printing

This section addresses common questions about DTF printing, providing clear and concise answers to help you better understand the technology and its applications.

| Question | Answer |

|---|---|

| What Is Dtf printing? | DTF stands for Direct to Film printing, a digital printing technology where designs are printed onto a special film and then transferred onto fabrics using heat and pressure. |

| What materials can DTF printing be used on? | DTF printing is versatile and can be used on various materials, including cotton, polyester, and their blends. |

| What equipment is needed for DTF printing? | You will need a modified inkjet printer, DTF inks, DTF film, DTF powder, RIP software, and a heat press. |

| How durable are DTF prints? | DTF prints are highly durable and resistant to washing and wear, making them ideal for garments and other textile products. |

| Is DTF printing cost-effective? | Yes, DTF printing is cost-effective, especially for small to medium-sized orders. It requires a relatively low initial investment and has low consumable costs. |

| What is the difference between DTF and DTG? | DTF prints on film first before transferring to the fabric, while DTG prints directly onto the garment. DTF is more versatile in terms of fabric compatibility and requires a lower initial investment. |

| How do I prepare a design for DTF printing? | Ensure your design is high-resolution and save it in a compatible format, such as PNG or TIFF. Create a white underbase layer if printing on dark fabrics. |

| How do I cure DTF powder? | Place the powdered film in a curing oven at the recommended temperature and time until the powder is melted and the surface is smooth. |

| What are common challenges in DTF printing? | Common challenges include ink clogging, powder adhesion, film release, and color bleeding. Regular maintenance and proper techniques can help overcome these issues. |

| How do I wash and care for DTF prints? | Wash garments inside out in cold water on a gentle cycle. Dry on low heat or hang to dry. Avoid using bleach or harsh detergents. |

| What are the business opportunities in DTF? | DTF printing opens up opportunities in custom apparel printing, promotional products, personalized gifts, and niche markets. |

| What are the future trends in DTF printing? | Future trends include advancements in ink technology, automation and efficiency, expanding applications, sustainable practices, personalization and customization, and integration with e-commerce. |

| Where can I get help with DTF printing? | WHAT.EDU.VN is here to provide free answers to all your DTF printing questions. Our experts are available to assist you with any issues or concerns you may have. |

| Where to find DTF Printing supplies? | DTF printing supplies can be found on several online marketplaces, such as Amazon, Alibaba, and specialized printing equipment distributors. |

| What is a DTF printer? | A DTF printer is a modified inkjet printer used to print designs on special DTF film. These printers are adapted to handle DTF inks and films, providing the necessary precision and control for high-quality prints. |

10. Call to Action: Get Your DTF Printing Questions Answered for Free

Are you struggling to find reliable and free answers to your DTF printing questions? Do you need expert advice on how to improve your printing process or troubleshoot common issues? Look no further. At WHAT.EDU.VN, we offer a free question and answer service that connects you with knowledgeable experts who can provide the solutions you need.

10.1. Why Choose WHAT.EDU.VN?

- Free Service: Get your DTF printing questions answered without any cost.

- Expert Advice: Our team of experts has years of experience in the DTF printing industry and can provide valuable insights and solutions.

- Quick Responses: Receive timely and accurate answers to your questions, helping you resolve issues quickly and efficiently.

- Comprehensive Support: Whether you’re a beginner or an experienced printer, we offer support for all skill levels.

- Community Knowledge: Benefit from the collective knowledge of our community of printers and experts.

10.2. How to Get Your Questions Answered

- Visit WHAT.EDU.VN: Go to our website at WHAT.EDU.VN.

- Submit Your Question: Use our easy-to-use question submission form to ask your DTF printing question.

- Receive an Answer: Our experts will review your question and provide a detailed and helpful answer.

- Engage with the Community: Join our community of printers and experts to discuss your questions and share your knowledge.

10.3. Common Questions We Can Help With

- Equipment Selection: Need help choosing the right DTF printer, inks, or other equipment?

- Printing Techniques: Looking for advice on improving your printing techniques or troubleshooting common issues?

- Color Management: Struggling with color matching or achieving accurate colors?

- Maintenance: Need help with maintaining your DTF printing equipment?

- Business Advice: Looking for tips on starting or growing your DTF printing business?

10.4. Don’t Hesitate, Ask Now

Don’t let your DTF printing questions go unanswered. Visit WHAT.EDU.VN today and get the free expert advice you need to succeed. Our mission is to provide accessible, reliable, and cost-effective solutions for all your DTF printing needs. Contact us today and let us help you achieve your printing goals.

Contact Information:

- Address: 888 Question City Plaza, Seattle, WA 98101, United States

- WhatsApp: +1 (206) 555-7890

- Website: WHAT.EDU.VN

11. Conclusion

DTF printing is a versatile and cost-effective method for creating high-quality, durable prints on a wide range of fabrics. Whether you’re a small business owner, a hobbyist, or a large-scale manufacturer, DTF printing offers numerous opportunities to customize apparel, promotional products, and personalized gifts. By understanding the process, equipment, and best practices outlined in this guide, you can maximize your DTF printing potential and achieve outstanding results. And remember, if you ever have any questions or need expert advice, what.edu.vn is here to provide free answers and support every step of the way. Start exploring the world of DTF printing today and unleash your creativity!