Fiberglass: What is it made of? Explore the composition, diverse applications, and numerous benefits of fiberglass with WHAT.EDU.VN. Discover the common ingredients and learn about the versatility of glass-reinforced plastic as we discuss its properties and manufacturing.

1. Understanding Fiberglass: A Comprehensive Overview

Fiberglass is a composite material renowned for its strength, durability, and versatility. Its widespread use in various industries stems from its unique combination of properties, making it an ideal choice for numerous applications. Let’s delve into the world of fiberglass and explore its composition, manufacturing process, applications, and benefits.

2. Decoding the Composition: What’s Inside Fiberglass?

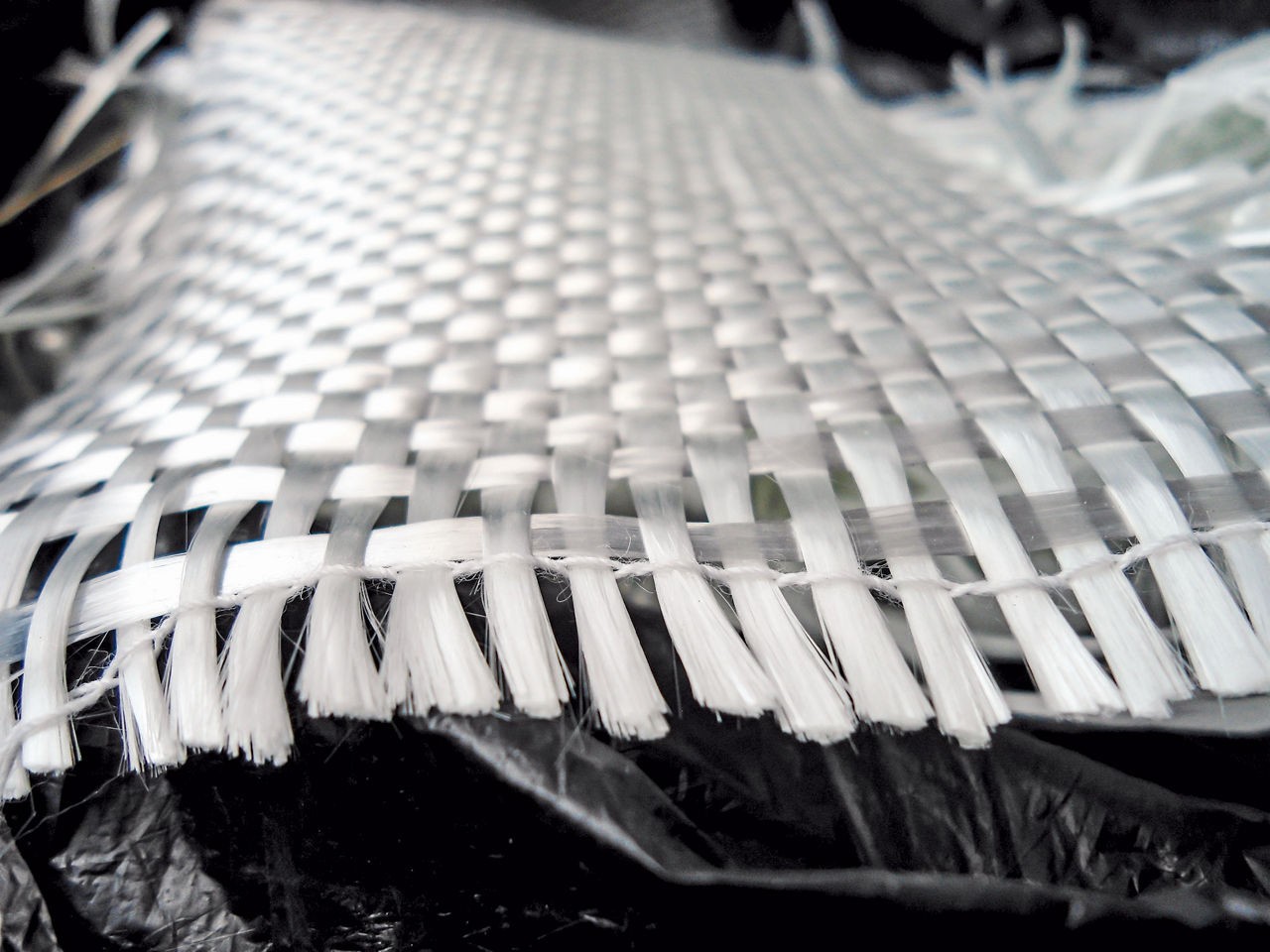

Fiberglass, at its core, is a composite material. This means it’s made by combining two or more materials with different physical and chemical properties. When combined, they produce a material with characteristics unlike the individual components. In the case of fiberglass, these components are glass fibers and a resin matrix.

2.1. Glass Fibers: The Backbone of Fiberglass

The primary component of fiberglass is, of course, glass fibers. These fibers provide the strength and structural integrity of the composite material. However, not all glass fibers are created equal. Different types of glass are used to manufacture fiberglass, each with its unique properties and applications.

2.1.1. E-Glass: The Most Common Type

E-glass, or electrical glass, is the most widely used type of glass fiber in fiberglass production. Its popularity stems from its excellent electrical insulation properties, high strength, and resistance to heat and chemicals. E-glass is typically composed of silica, alumina, calcium oxide, and boron oxide.

2.1.2. S-Glass: High Strength and Performance

S-glass, or structural glass, is a high-performance glass fiber known for its exceptional strength and stiffness. It is typically used in applications where high strength-to-weight ratio is critical, such as aerospace components and high-performance sporting equipment. S-glass is composed of silica, alumina, and magnesium oxide.

2.1.3. C-Glass: Corrosion Resistance

C-glass, or chemical glass, is a specialized glass fiber designed for applications requiring high resistance to corrosion from acids and other chemicals. It is commonly used in chemical storage tanks and pipelines. C-glass is composed of silica, sodium oxide, and calcium oxide.

2.1.4. A-Glass: Soda-Lime Glass

A-glass, also known as soda-lime glass, is similar in composition to the glass used for windows and bottles. It is typically used in applications where high strength and chemical resistance are not critical, such as insulation. A-glass is composed of silica, sodium oxide, calcium oxide, and magnesium oxide.

2.2. Resin Matrix: Binding the Fibers Together

The resin matrix is the second essential component of fiberglass. It serves to bind the glass fibers together and distribute stress evenly throughout the material. The resin also protects the fibers from environmental damage and provides the finished product with its shape and surface finish. Several types of resins are used in fiberglass production, each with its unique properties and applications.

2.2.1. Polyester Resin: Cost-Effective and Versatile

Polyester resin is the most common type of resin used in fiberglass production due to its affordability and versatility. It offers good strength, chemical resistance, and electrical properties, making it suitable for a wide range of applications.

2.2.2. Vinyl Ester Resin: Enhanced Corrosion Resistance

Vinyl ester resin offers improved corrosion resistance compared to polyester resin, making it ideal for applications in harsh chemical environments. It also provides higher strength and toughness than polyester resin.

2.2.3. Epoxy Resin: Superior Strength and Adhesion

Epoxy resin is known for its superior strength, adhesion, and chemical resistance. It is typically used in high-performance applications where these properties are critical, such as aerospace components and marine structures.

2.2.4. Phenolic Resin: Fire Resistance

Phenolic resin is a thermosetting resin known for its excellent fire resistance, low smoke emission, and low cost. It is commonly used in insulation and other applications where fire safety is a concern.

3. The Manufacturing Process: How Fiberglass is Made

The manufacturing of fiberglass involves a series of steps to combine the glass fibers and resin matrix into a finished product. The specific process varies depending on the desired product shape, size, and properties. However, the following are the most common methods:

3.1. Wet Lay-Up: A Manual Process

The wet lay-up process is a manual method where layers of fiberglass mat or cloth are placed in a mold and saturated with resin. Rollers or brushes are used to ensure the resin thoroughly wets the fibers and removes any air bubbles. Once the resin cures, the part is removed from the mold. This method is suitable for low-volume production of large and complex parts.

3.2. Spray Lay-Up: A Faster Alternative

The spray lay-up process is similar to the wet lay-up but uses a chopper gun to simultaneously spray chopped glass fibers and resin into the mold. This method is faster than wet lay-up and suitable for medium-volume production of parts with relatively simple shapes.

3.3. Filament Winding: For Cylindrical Shapes

Filament winding is a process where continuous strands of glass fibers are wound around a rotating mandrel. The fibers are saturated with resin as they are wound, and the mandrel is removed after the resin cures. This method is ideal for manufacturing cylindrical parts such as pipes and tanks.

3.4. Pultrusion: Continuous Production of Profiles

Pultrusion is a continuous molding process where glass fibers are pulled through a resin bath and then through a heated die. The die shapes the material and cures the resin. This method is used to produce constant cross-section profiles such as rods, beams, and channels.

3.5. Compression Molding: High-Volume Production

Compression molding involves placing a preform of fiberglass and resin into a heated mold and then closing the mold under high pressure. The heat and pressure cause the resin to melt and flow, filling the mold cavity. This method is suitable for high-volume production of complex parts with tight tolerances.

3.6. Resin Transfer Molding (RTM): Closed-Mold Process

Resin transfer molding (RTM) is a closed-mold process where dry glass fibers are placed in a mold, and then resin is injected into the mold under pressure. This method produces parts with smooth surfaces on both sides and is suitable for medium-volume production of complex parts.

4. The Versatile Applications of Fiberglass

Fiberglass finds applications in a wide range of industries due to its unique combination of properties. Here are some of the most common applications:

4.1. Construction Industry: Insulation and Structural Components

In the construction industry, fiberglass is widely used for insulation, roofing, siding, and structural components. Fiberglass insulation provides excellent thermal and acoustic insulation, helping to reduce energy consumption and noise levels in buildings. Fiberglass reinforced polymer (FRP) composites are used for structural components such as beams, columns, and panels, offering high strength-to-weight ratio and corrosion resistance.

4.2. Transportation Industry: Lightweight and Durable Parts

The transportation industry utilizes fiberglass for manufacturing lightweight and durable parts for cars, trucks, boats, and airplanes. Fiberglass composites are used for body panels, hoods, doors, and interior components, reducing vehicle weight and improving fuel efficiency. In marine applications, fiberglass is used for boat hulls, decks, and other structural components due to its water resistance and durability.

4.3. Aerospace Industry: High-Performance Materials

The aerospace industry relies on fiberglass composites for manufacturing high-performance materials for aircraft structures, interior components, and radomes. Fiberglass composites offer high strength-to-weight ratio, stiffness, and resistance to fatigue and corrosion, making them ideal for demanding aerospace applications.

4.4. Sporting Goods Industry: Strength and Flexibility

Fiberglass is used in the sporting goods industry for manufacturing various products such as skis, surfboards, fishing rods, and bows. Fiberglass provides the necessary strength and flexibility for these products to perform optimally.

4.5. Electrical Industry: Insulation and Protection

The electrical industry utilizes fiberglass for insulation, circuit boards, and enclosures. Fiberglass offers excellent electrical insulation properties and protects electrical components from environmental damage.

4.6. Consumer Products: Durable and Aesthetic Designs

Fiberglass is also found in various consumer products such as bathtubs, shower stalls, furniture, and decorative items. Fiberglass provides durability, water resistance, and design flexibility for these products.

5. Advantages of Fiberglass: Why Choose Fiberglass?

Fiberglass offers numerous advantages over other materials, making it a popular choice for a wide range of applications. Some of the key benefits of fiberglass include:

5.1. High Strength-to-Weight Ratio: Lightweight Strength

Fiberglass is a lightweight material with a high strength-to-weight ratio. This means it offers excellent strength while adding minimal weight to the structure. This property is particularly beneficial in transportation and aerospace applications where weight reduction is critical.

5.2. Corrosion Resistance: Durable in Harsh Environments

Fiberglass is highly resistant to corrosion from chemicals, moisture, and other environmental factors. This makes it ideal for applications in harsh environments such as chemical plants, marine structures, and underground pipelines.

5.3. Electrical Insulation: Safe and Reliable

Fiberglass offers excellent electrical insulation properties, making it safe and reliable for electrical applications. It can be used to insulate wires, cables, and electrical components, preventing electrical shock and short circuits.

5.4. Design Flexibility: Versatile Shapes and Forms

Fiberglass can be molded into various shapes and forms, offering design flexibility for manufacturers. It can be used to create complex parts with intricate details, allowing for innovative and aesthetically pleasing designs.

5.5. Durability and Longevity: Long-Lasting Performance

Fiberglass is a durable material that can withstand harsh weather conditions, impact, and wear and tear. It offers long-lasting performance and requires minimal maintenance, making it a cost-effective choice for many applications.

5.6. Cost-Effectiveness: Affordable Solution

Fiberglass is a cost-effective material compared to other high-performance materials such as carbon fiber and aluminum. It offers a good balance of performance and price, making it an attractive option for budget-conscious projects.

6. Addressing Common Questions About Fiberglass

Fiberglass often raises questions about its safety, environmental impact, and handling. Let’s address some of the most common concerns:

6.1. Is Fiberglass Safe? Addressing Health Concerns

Fiberglass, in its finished form, is generally considered safe. However, inhaling small fiberglass particles during cutting or installation can cause temporary irritation to the skin, eyes, and respiratory tract. It is recommended to wear protective clothing, gloves, and a dust mask when handling fiberglass to minimize exposure.

6.2. Environmental Impact: Recycling and Sustainability

The environmental impact of fiberglass production and disposal is a growing concern. While fiberglass is not easily recyclable, efforts are being made to develop recycling technologies and sustainable manufacturing practices. Some manufacturers are using recycled glass in fiberglass production and exploring bio-based resins as alternatives to petroleum-based resins.

6.3. Handling Fiberglass: Safety Precautions

When handling fiberglass, it is essential to take certain safety precautions to minimize exposure to fiberglass particles. These precautions include wearing protective clothing, gloves, and a dust mask, as well as working in a well-ventilated area.

7. Innovations in Fiberglass Technology

Fiberglass technology is constantly evolving, with ongoing research and development focused on improving its properties, reducing its environmental impact, and expanding its applications. Some of the latest innovations include:

7.1. Bio-Based Resins: Sustainable Alternatives

Researchers are developing bio-based resins derived from renewable resources such as plants and algae as alternatives to petroleum-based resins. These bio-based resins offer a more sustainable and environmentally friendly option for fiberglass production.

7.2. Recycled Glass: Reducing Waste

Some manufacturers are incorporating recycled glass into fiberglass production, reducing waste and conserving natural resources. Recycled glass can be used to replace virgin raw materials in the glass fiber manufacturing process.

7.3. Nanomaterials: Enhanced Properties

The incorporation of nanomaterials such as carbon nanotubes and graphene into fiberglass composites can enhance their mechanical, electrical, and thermal properties. These nanomaterials can improve the strength, stiffness, conductivity, and heat resistance of fiberglass composites.

8. Fiberglass vs. Other Materials: A Comparison

Fiberglass is often compared to other materials such as wood, metal, and carbon fiber. Here’s a brief comparison:

| Material | Strength-to-Weight Ratio | Corrosion Resistance | Electrical Insulation | Cost |

|---|---|---|---|---|

| Fiberglass | High | Excellent | Excellent | Moderate |

| Wood | Moderate | Poor | Good | Low |

| Metal | High | Poor | Poor | Moderate |

| Carbon Fiber | Very High | Excellent | Good | High |

9. The Future of Fiberglass: Promising Developments

The future of fiberglass looks promising, with ongoing research and development focused on improving its properties, reducing its environmental impact, and expanding its applications. As new technologies emerge and sustainable practices become more prevalent, fiberglass is expected to remain a versatile and valuable material for various industries.

9.1. Advancements in Manufacturing Processes

New manufacturing processes such as automated fiber placement and 3D printing are being developed to improve the efficiency and precision of fiberglass composite production. These processes can reduce waste, lower costs, and enable the creation of complex shapes and structures.

9.2. Smart Fiberglass Composites

Researchers are exploring the integration of sensors and other electronic components into fiberglass composites to create smart materials that can monitor their own condition and performance. These smart fiberglass composites can be used in infrastructure, transportation, and aerospace applications to improve safety and reliability.

9.3. Sustainable Fiberglass Solutions

The development of sustainable fiberglass solutions is a major focus of ongoing research. This includes the use of bio-based resins, recycled glass, and eco-friendly manufacturing processes to reduce the environmental impact of fiberglass production and disposal.

10. Need Answers? Ask WHAT.EDU.VN!

Do you have more questions about fiberglass or any other topic? Don’t hesitate to ask! WHAT.EDU.VN provides a free platform to ask any question and receive prompt, accurate answers from experts and knowledgeable community members. Whether you’re a student, professional, or simply curious, WHAT.EDU.VN is your go-to resource for finding the information you need.

10.1. Free Question-Answering Platform

WHAT.EDU.VN offers a completely free question-answering platform. Ask any question you have and get helpful answers from our community.

10.2. Connect with Knowledgeable Experts

Our platform connects you with experts in various fields who are ready to share their knowledge and insights.

10.3. Get Answers Quickly and Easily

Receive answers to your questions quickly and easily, saving you time and effort in your search for information.

11. Frequently Asked Questions (FAQs) About Fiberglass

| Question | Answer |

|---|---|

| What is fiberglass made of? | Fiberglass is a composite material made of glass fibers and a resin matrix. The glass fibers provide strength, while the resin binds the fibers together. |

| What are the different types of fiberglass? | Common types include E-glass (electrical), S-glass (structural), C-glass (chemical), and A-glass (soda-lime). Each type has unique properties and applications. |

| What is fiberglass used for? | Fiberglass is used in construction, transportation, aerospace, sporting goods, and electrical industries for insulation, structural components, lightweight parts, and electrical insulation. |

| Is fiberglass harmful to health? | Fiberglass is generally safe in its finished form. However, inhaling small particles during handling can cause temporary irritation. Protective gear is recommended. |

| Is fiberglass recyclable? | Fiberglass recycling is challenging but improving. Efforts are focused on developing recycling technologies and using recycled glass in production. |

| How is fiberglass manufactured? | Manufacturing methods include wet lay-up, spray lay-up, filament winding, pultrusion, compression molding, and resin transfer molding, each suited for different product shapes and volumes. |

| What are the advantages of fiberglass? | High strength-to-weight ratio, corrosion resistance, electrical insulation, design flexibility, durability, and cost-effectiveness. |

| How does fiberglass compare to carbon fiber? | Fiberglass is more affordable and offers good performance, while carbon fiber is stronger and lighter but more expensive. |

| What are bio-based resins? | Bio-based resins are sustainable alternatives to petroleum-based resins, derived from renewable resources like plants and algae. |

| What are some innovations in fiberglass? | Innovations include bio-based resins, recycled glass, nanomaterials for enhanced properties, automated manufacturing processes, and smart fiberglass composites with integrated sensors. |

| Where can I ask more questions about fiberglass? | Visit WHAT.EDU.VN to ask any question and receive prompt, accurate answers from experts and knowledgeable community members. |

12. Conclusion: Embracing the Potential of Fiberglass

Fiberglass is a versatile and valuable material with a wide range of applications and numerous benefits. Its unique combination of strength, durability, corrosion resistance, and design flexibility makes it an ideal choice for various industries. As technology advances and sustainable practices become more prevalent, fiberglass is expected to remain a crucial material for years to come. Have any lingering questions? Visit WHAT.EDU.VN, where answering your questions is free.

Windmill turbines, watercraft, and thousands of other products are strong yet lightweight because they are made from fiberglass.

13. Call to Action: Ask Your Questions on WHAT.EDU.VN

Do you have questions about fiberglass or any other topic? Don’t keep wondering – get the answers you need!

At WHAT.EDU.VN, we understand the frustration of searching endlessly for reliable information. That’s why we’ve created a platform where you can ask any question and receive clear, helpful answers from experts and a supportive community.

Why choose WHAT.EDU.VN?

- It’s Free: Ask as many questions as you like, without any cost.

- Get Answers Fast: Our community is active and ready to help.

- Expert Knowledge: Connect with knowledgeable individuals in various fields.

- Easy to Use: Our platform is designed to be simple and intuitive.

Stop struggling to find answers. Visit WHAT.EDU.VN today and ask your question!

Contact us:

Address: 888 Question City Plaza, Seattle, WA 98101, United States

Whatsapp: +1 (206) 555-7890

Website: what.edu.vn