Lyocell fabric is a sustainable and versatile material gaining popularity in the textile industry, and WHAT.EDU.VN is here to answer all your questions about it. It’s known for its softness, strength, and eco-friendly production. Learn about its uses, benefits, and how it compares to other fabrics like rayon and cotton. Discover the wonders of this innovative material – also known as Tencel, a modern fabric and eco-friendly option.

1. What is Lyocell Fabric?

Lyocell is a semi-synthetic fabric prized for its softness, strength, and environmentally conscious production. It is a form of rayon derived primarily from wood cellulose. It’s frequently used as a substitute for cotton or silk.

Originally developed by American Enka in 1972, lyocell gained popularity in the latter part of the 20th century. While primarily made from organic materials, whether lyocell fabric is truly better for the environment than fully synthetic fibers is debatable. But at WHAT.EDU.VN we are always here to provide fast, free answers to all of your questions.

1.1. What is Tencel?

At American Enka, lyocell fabric only made it through the pilot phase of development before the project was abandoned. It wasn’t until the 1980s that a British company called Courtaulds Fibres picked up the pieces and created a new fabric called Tencel based on lyocell research. These two fabrics are chemically identical, and the terms Tencel and lyocell can be used interchangeably.

Consumers generally find lyocell fabric to be soft to the touch, and many people can’t tell the difference between this fabric and cotton. Lyocell fabric is very strong whether it is wet or dry, and it is more resistant to pilling than cotton. Textile manufacturers like the fact that it’s easy to mix this fabric with other types of textiles; for instance, it plays well with cotton, silk, rayon, polyester, nylon, and wool.

Do you have more questions about how lyocell and Tencel compare? Ask them for free on WHAT.EDU.VN and get answers from our knowledgeable community.

1.2. What are the Main Characteristics of Lyocell Fabric?

Here’s a quick look at the key features of lyocell:

| Feature | Description |

|---|---|

| Breathability | Highly breathable, keeping you cool and comfortable. |

| Moisture-Wicking | Excellent moisture-wicking properties, ideal for activewear. |

| Strength | Strong both when wet and dry, enhancing durability. |

| Softness | Soft to the touch, often compared to cotton or silk. |

| Pilling Resistance | More resistant to pilling compared to cotton. |

| Versatility | Blends well with other fabrics like cotton, silk, and polyester. |

| Sustainability | Made from sustainably sourced wood pulp using eco-friendly processes. |

2. How is Lyocell Fabric Made?

Tencel is almost chemically identical to rayon, but a somewhat different process is used to make this rayon derivative. Unlike the rayon production process, the lyocell fabric production process involves the use of a direct solvent instead of an indirect solvent. A solvent spinning technique is used to create Tencel, which means that unlike the case in the production of rayon, the Tencel production process doesn’t cause any significant chemical changes to the chemical structure of cellulose.

While fabrics derived from cellulose have been around for nearly 200 years, they have only been in mass production since the beginning of the 20th century. These fabrics were originally designed as substitutes for silk, and pioneers of cellulose fabrics attempted to recreate the process that silkworms use to make real silk.

The first cellulose fabric to be mass-produced was rayon, and to this day, rayon is made with an extrusion method. As one of the newest cellulose fabric production methods, production of lyocell improves on the production methods used to make rayon. It is more efficient, it produces less waste, and it results in a product that is less synthetic than rayon.

Still curious about the specifics? Our experts at WHAT.EDU.VN can give you a detailed breakdown – just ask.

2.1. What are the Steps in the Lyocell Production Process?

Here’s a breakdown of the lyocell production process:

- Sourcing Wood Pulp: Chips of hardwood like oak or birch are used as the raw materials for the cellulose that is used in this fabric. The trees used for these purposes are usually grown on managed tree farms.

- Pulping: Once the trees arrive at a Tencel production facility, they are broken down into chips and loaded into a vat of chemical digesters, which soften the chips into pulp. This pulp is then washed in water, and bleach may also be used to sanitize it.

- Drying: Next, it is dried in a sheet and it is rolled into spools. Most cellulose rolls are enormous and weigh about 500 pounds.

- Dissolving: These sheets are then broken into squares measuring approximately one inch across, and these squares are placed in pressurized and heated vats of amine oxide, which is the primary solvent used to make lyocell fabric.

- Filtering: Once the cellulose has dissolved into a clear liquid, it is filtered and pumped through spinnerets.

- Spinning: As it is forced through spinnerets, cellulose is turned into long, thin fibers. The resulting fibers are immersed in a vat of diluted amine oxide to set, and they are then washed with demineralized water.

- Finishing: The lyocell fibers are then dried, and a lubricant, such as silicone or soap, is applied. The fibers are now considered to be in a state called tow, and these bundles of tow are placed in a crimper that compresses the fiber. Next, they are carded, which separates and orders the strands. Lastly, the fibers are cut, and they are then ready to be turned into a variety of different products.

Compared to rayon, the Tencel production process requires far fewer steps and takes much less time. Also, since the amine oxide used to make this fabric can be recovered, making lyocell fabric is much less wasteful than making rayon.

2.2. What is the Environmental Impact of Lyocell Production?

Compared to other cellulose textiles, lyocell is much better for the environment. While the process of producing this fabric is similar to that which is used to make rayon and other cellulose fabrics, production of Tencel doesn’t introduce any toxins into the environment if it is done correctly.

Unlike similar textiles, lyocell production employs a “closed loop” extraction process, which means that the same batch of amine oxide is used to extract multiple batches of Tencel. For comparison, production of viscose rayon involves a number of different chemical processes that do not employ a closed loop system, and these chemicals are then introduced into the environment in the form of contaminated water.

It is, however, important to remember that lyocell is made from trees, and a great deal of tree material is wasted in the production of this fabric. If trees for Tencel production are not grown sustainably, production of this material could have a negative environmental impact, and not all Tencel producers are guaranteed to follow the sustainable closed-loop extraction model.

Have eco-conscious questions? Ask WHAT.EDU.VN and get reliable, free answers.

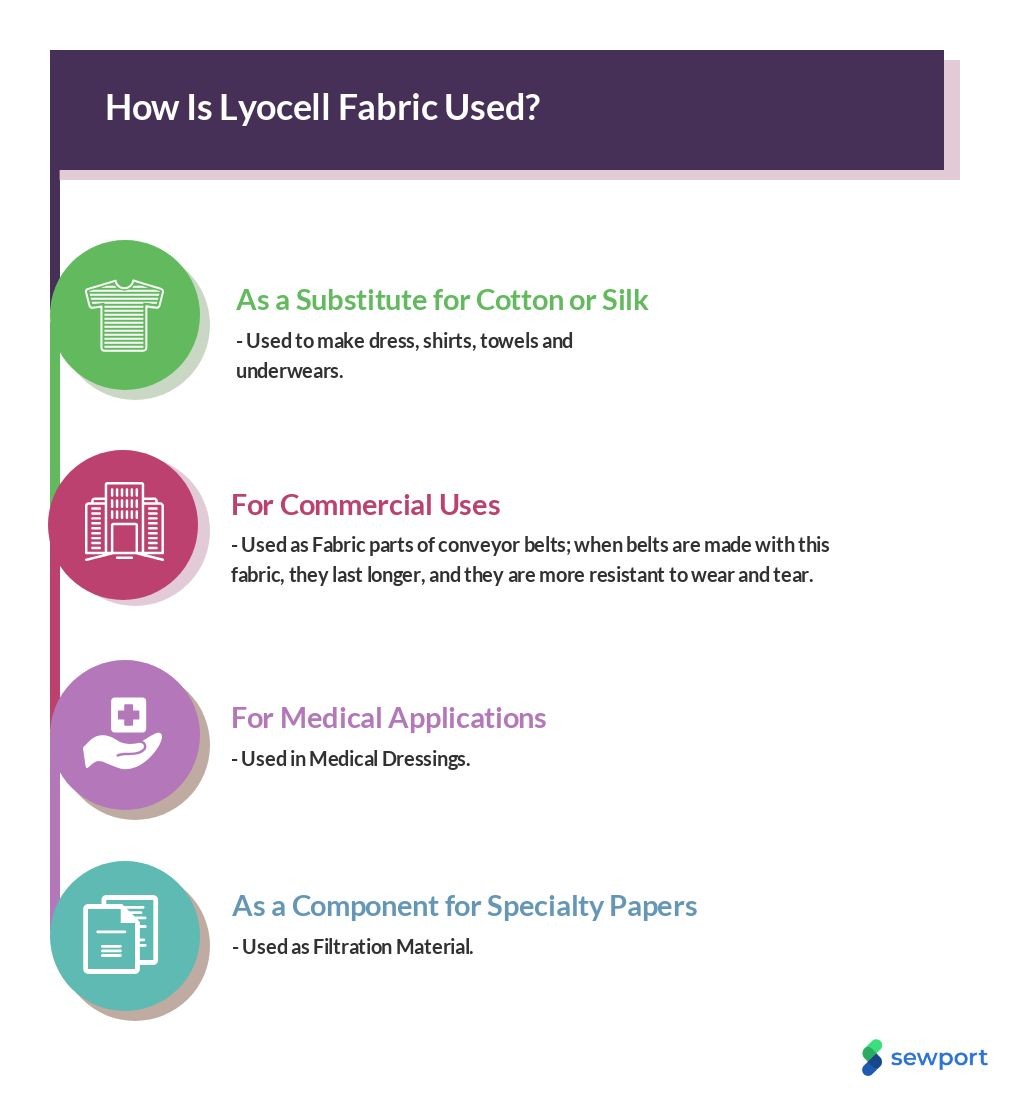

3. How is Lyocell Fabric Used?

Tencel is usually used as a substitute for cotton or silk. This fabric feels like soft cotton, and it is used to make everything from dress shirts to towels to underwear.

While some garments are made entirely from lyocell, it is more common to see this fabric mixed with other types of fabrics like cotton or polyester. Since Tencel is so strong, when it is mixed with other fabrics, the resulting composite fabric is stronger than cotton or polyester on its own.

In addition to garments, this fabric is used in a variety of commercial settings. For instance, many manufacturers have substituted lyocell for cotton in the fabric parts of conveyor belts; when belts are made with this fabric, they last longer, and they are more resistant to wear and tear.

Furthermore, Tencel is quickly becoming a favorite fabric for medical dressings. In life or death situations, having a fabric that is highly tensile is very important, and Tencel has proved itself to be stronger than fabrics that were used for medical dressings in the past. This fabric’s high absorbancy profile also makes it an ideal material to use in medical applications.

3.1. What are the Common Applications of Lyocell?

Lyocell’s versatility makes it suitable for a wide range of products:

- Clothing: Dress shirts, casual wear, activewear, and underwear.

- Home Textiles: Bed sheets, towels, and upholstery.

- Industrial Uses: Conveyor belts and specialty papers.

- Medical: Medical dressings due to its high absorbency and strength.

3.2. What are the Benefits of Using Lyocell in Clothing?

Lyocell offers numerous advantages when used in clothing:

- Comfort: Soft and gentle on the skin.

- Moisture Management: Keeps you dry and comfortable by wicking away moisture.

- Durability: Strong fibers ensure long-lasting garments.

- Wrinkle Resistance: Less prone to wrinkles compared to cotton.

- Eco-Friendliness: Produced using sustainable practices.

Got more questions about the best uses for lyocell? The experts at WHAT.EDU.VN are ready to provide fast, free answers.

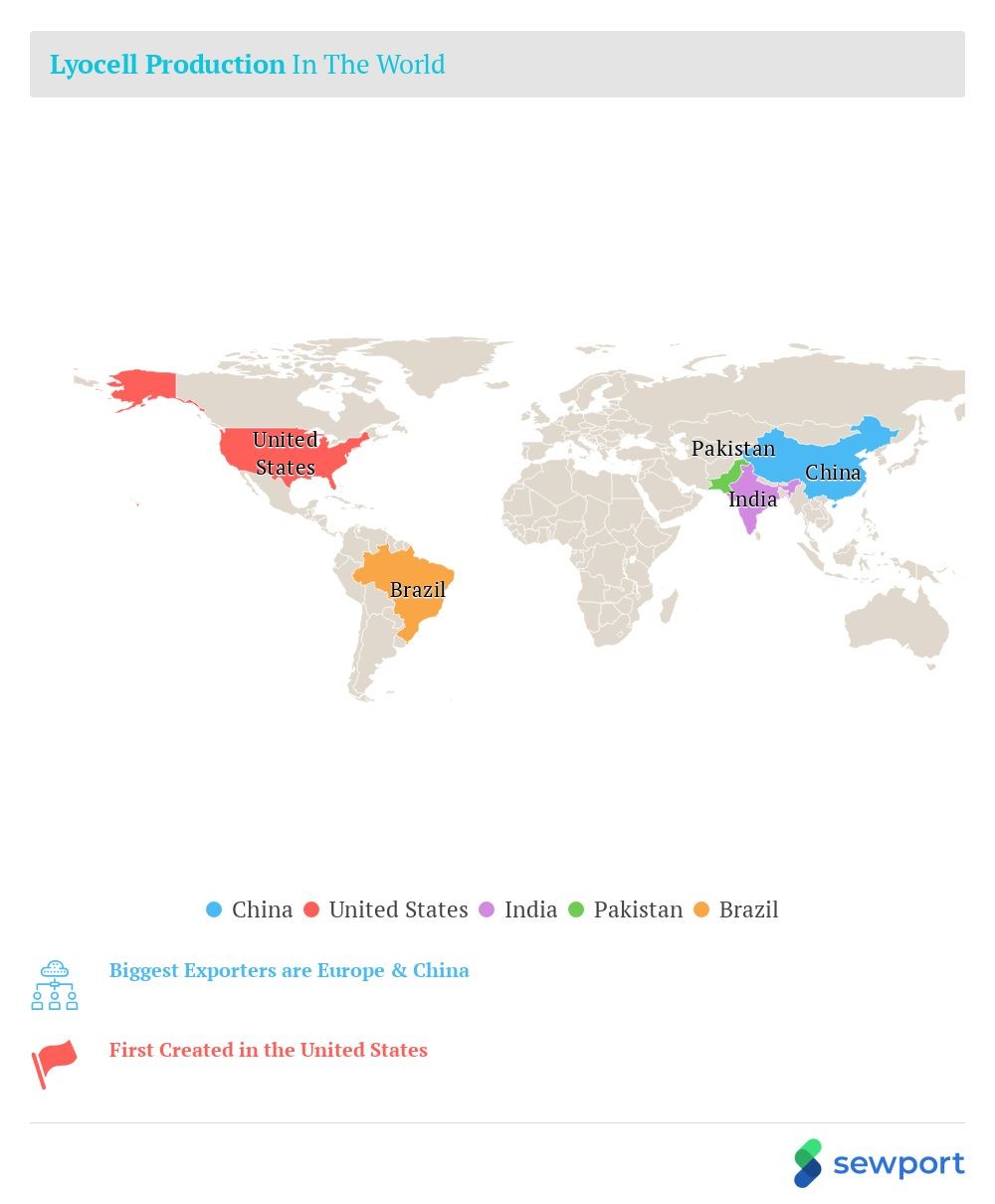

4. Where is Lyocell Fabric Produced?

When lyocell fabric was first created, it was only produced at the American Enka factory in Enka, North Carolina. When Enka stopped producing this substance, however, production moved entirely to the United Kingdom when Courtaulds Fibers branded this fabric as Tencel.

Eventually, Tencel production expanded to the Courtaulds plant in Mobile, Alabama, and until the late 1990s, this fabric was not made anywhere else in the world. In 1998, however, Courtalds was sold to Akzo Nobel, which is a Dutch international corporation specializing in paints. Akzo Nobel went on to sell the rights to Tencel to a private equity firm named CVC partners, which promptly sold its Tencel division to Lenzing AG, which is an international textile corporation based in Austria.

While Lenzing AG has a variety of different factories in Europe, a great deal of their production has moved overseas to countries like China and Indonesia. While some Tencel is still produced in countries like Austria, the United Kingdom, and the USA, the majority of this fabric is now produced in China.

Since Lenzing now holds the Tencel patent, it remains the largest producer of this textile in the world. A variety of smaller companies may also make this fabric in minuscule quantities, but if you’ve worn a lyocell garment, chances are it was made by Lenzing AG in one of their Chinese factories.

4.1. Which Countries are the Main Producers of Lyocell?

The primary lyocell producing countries are:

- China

- Austria

- United Kingdom

- United States

- Indonesia

4.2. Who are the Major Manufacturers of Lyocell?

The largest producer of lyocell fabric is Lenzing AG, which holds the Tencel patent.

5. How Much Does Lyocell Fabric Cost?

Rayon and other cellulose fabrics were originally produced as cheaper alternatives to silk. While silk production is all-natural and relatively sustainable, it’s hard to produce silk in large quantities, which prompted the birth of the “artificial silk” revolution that ultimately resulted in the development of modern rayon.

While it’s true that cellulose fabrics remain cheaper to produce than silk, the same can’t be said for cotton. While prices of cotton and cellulose fabrics fluctuate, cotton has been significantly cheaper to produce in the last decade or so. If global economic trends remain stable, cotton will remain less expensive than lyocell and similar fabrics from a production standpoint.

However, the difference in price between cotton and Tencel is nearly negligible, and some manufacturers may prefer the process of producing cellulose fabrics to the process of manufacturing cotton. Lyocell, in particular, is one of the simplest cellulose fabrics to produce, and it generates very little waste.

Even if cellulose fabrics become less popular than cotton due to price fluctuations, lyocell fabric is much more useful than cotton in a number of applications. This textile’s tensility is off the charts, and it is highly durable in commercial applications. Manufacturers are more than happy to pay slightly higher prices for these benefits.

5.1. Is Lyocell More Expensive Than Cotton?

While prices can fluctuate, lyocell is generally slightly more expensive to produce than cotton. However, the price difference is often negligible, and manufacturers may prefer lyocell due to its ease of production and lower waste.

5.2. What Factors Influence the Price of Lyocell?

Several factors can influence the price of lyocell:

- Production Costs: The cost of sourcing wood pulp and processing it.

- Demand: Higher demand can drive up prices.

- Sustainability Practices: Eco-friendly production methods may increase costs.

- Market Conditions: Global economic factors and trade policies.

Still wondering about the best deals on lyocell? Ask the community at WHAT.EDU.VN for up-to-date information.

6. What Different Types of Lyocell Fabric Are There?

There is, from a chemical point of view, only one type of lyocell fabric. Even when this substance is called Tencel, it has the same chemical composition, and it is made using the same process.

However, there are a couple of fabrics that are very similar to lyocell fabric that you should be aware of as you learn more about this textile. Examples of these similar fabrics include:

- Viscose rayon: This fabric was the first type of cellulose textile to rise into popularity. Viscose rayon has been produced since the first few decades of the 20th century, and it was preceded by a number of cellulose fabric prototypes that were discontinued due to flammability or untenable production processes. Viscose rayon remains a popular fabric, and it is produced around the world. However, the viscose production process is much more complicated than the process that is used to create lyocell, and it is much more impactful on the environment. In some cases, viscose rayon may be cheaper to produce than Tencel, but it’s clear that this fabric is technologically outdated.

- Modal rayon: This type of rayon is relatively similar to Tencel in a number of ways. It is made with a simpler process than viscose rayon, and it is significantly more tensile than other types of cellulose fiber. This rayon production method was discovered in the 1940s, and it represents a technical leap forward in cellulose fabric production. However, many manufacturers around the world still produce viscose rayon instead of modal rayon.

6.1. How Does Lyocell Compare to Viscose Rayon?

Lyocell and viscose rayon are both cellulose fabrics, but they differ in production methods and environmental impact:

| Feature | Lyocell | Viscose Rayon |

|---|---|---|

| Production Process | Closed-loop system, less waste, fewer chemicals | More complex, higher waste, more chemicals |

| Environmental Impact | Lower | Higher |

| Strength | Stronger | Weaker |

| Softness | Very soft | Soft |

6.2. What is Modal Rayon?

Modal rayon is another type of rayon that is similar to lyocell. It is more tensile than viscose rayon and is produced using a simpler process.

7. How Does Lyocell Fabric Impact the Environment?

Compared to other cellulose textiles, lyocell is much better for the environment. While the process of producing this fabric is similar to that which is used to make rayon and other cellulose fabrics, production of Tencel doesn’t introduce any toxins into the environment if it is done correctly.

Unlike similar textiles, lyocell production employs a “closed loop” extraction process, which means that the same batch of amine oxide is used to extract multiple batches of Tencel. For comparison, production of viscose rayon involves a number of different chemical processes that do not employ a closed loop system, and these chemicals are then introduced into the environment in the form of contaminated water.

It is, however, important to remember that lyocell is made from trees, and a great deal of tree material is wasted in the production of this fabric. If trees for Tencel production are not grown sustainably, production of this material could have a negative environmental impact, and not all Tencel producers are guaranteed to follow the sustainable closed-loop extraction model.

7.1. What is the Closed-Loop Production Process?

The closed-loop production process is an environmentally friendly method used in lyocell production. It involves recycling the solvent (amine oxide) used to dissolve the wood pulp, minimizing waste and reducing the release of harmful chemicals into the environment.

7.2. Is Lyocell Production Sustainable?

Lyocell production is generally considered more sustainable than other cellulose fabrics like viscose rayon. However, it is essential to ensure that the wood pulp is sourced from sustainably managed forests and that producers adhere to the closed-loop system.

8. Lyocell Certifications Available

Lyocell can be certified as organic under certain circumstances. To receive this certification, producers of this fabric must use organic practices to produce the trees that they use for cellulose, and they must avoid using certain toxic chemicals in the production process.

Unlike rayon, the structure of Tencel isn’t altered by any chemicals, which means that the cellulose-based fabric that is produced and labeled as Tencel is technically made solely from cellulose derived from trees. However, since amine oxide is used in the Tencel production process, some purists may not view this fabric as completely organic.

8.1. How Can Lyocell be Certified as Organic?

To be certified as organic, lyocell producers must:

- Use organic practices to grow the trees used for cellulose.

- Avoid using toxic chemicals in the production process.

- Adhere to sustainable and environmentally friendly practices.

8.2. What Certifications Should Consumers Look For?

Consumers should look for certifications such as:

- Organic certification: Ensures the trees are grown using organic practices.

- OEKO-TEX Standard 100: Guarantees that the fabric has been tested for harmful substances.

- FSC (Forest Stewardship Council): Ensures that the wood pulp comes from responsibly managed forests.

Do you have any more questions about what to look for in lyocell products? Head over to WHAT.EDU.VN for free answers from our community of experts.

9. FAQ about Lyocell Fabric

| Question | Answer |

|---|---|

| What is the difference between lyocell and Tencel? | Lyocell is the generic name for the fiber, while Tencel is the brand name owned by Lenzing AG. They are essentially the same material. |

| Is lyocell biodegradable? | Yes, lyocell is biodegradable under the right conditions, as it is made from cellulose. |

| How do I care for lyocell clothing? | Lyocell clothing is typically machine washable. Check the care label for specific instructions. |

| Is lyocell suitable for sensitive skin? | Yes, lyocell is soft, smooth, and breathable, making it an excellent choice for sensitive skin. |

| Can lyocell be used in all types of clothing? | Yes, lyocell is versatile and can be used in various types of clothing, from casual wear to more formal attire. |

| Does lyocell shrink? | Lyocell has minimal shrinkage compared to other fabrics like cotton. |

| Is lyocell wrinkle-resistant? | Yes, lyocell is more wrinkle-resistant than cotton, making it a great option for travel and everyday wear. |

| How does lyocell compare to silk? | Lyocell offers a similar soft and luxurious feel to silk but is more durable and easier to care for. |

| Is lyocell good for hot weather? | Yes, lyocell’s breathability and moisture-wicking properties make it ideal for hot weather. |

| Where can I buy lyocell fabric or clothing? | Lyocell fabric and clothing are available at many textile retailers, department stores, and online marketplaces. Look for the Tencel brand for guaranteed quality and sustainability. |

10. Why Choose Lyocell Fabric?

Lyocell fabric is an excellent choice for those seeking a sustainable, comfortable, and versatile material. Its eco-friendly production process, combined with its numerous benefits, makes it a superior option for clothing, home textiles, and industrial applications.

Still have burning questions about lyocell? Don’t hesitate. Visit WHAT.EDU.VN today and ask your question for free. Our community of experts is ready to help.

Are you tired of searching endlessly for answers? Do you have questions that need expert insights? WHAT.EDU.VN is here to provide you with a seamless and FREE question-answering experience.

Address: 888 Question City Plaza, Seattle, WA 98101, United States

WhatsApp: +1 (206) 555-7890

Website: WHAT.EDU.VN

Visit what.edu.vn today and experience the ease of getting your questions answered quickly and accurately!