What Is The Strongest Metal On Earth? It’s a question that sparks curiosity, and WHAT.EDU.VN is here to provide a comprehensive answer. Uncover the strength of different metals, exploring hardness, tensile strength, and applications. Find reliable insights and explore material strength with us to find the ultimate solution for your project, enhancing material selection and component durability.

Table of Contents

1. Understanding Metal Strength

2. Types of Metal Strength

2.1. Tensile Strength

2.2. Compressive Strength

2.3. Yield Strength

2.4. Impact Strength

3. Top Contenders for the Strongest Metal

3.1. Chromium

3.2. Inconel

3.3. Stainless Steel

3.4. Titanium

3.5. Tool Steel

3.6. Tungsten

4. Tungsten vs. Titanium: A Detailed Comparison

5. Factors Influencing Metal Strength

6. Applications of Strong Metals

7. Emerging Strong Metals and Alloys

8. The Future of Strong Metals

9. FAQ: Frequently Asked Questions about Metal Strength

10. Need More Help? Ask WHAT.EDU.VN!

1. Understanding Metal Strength

Determining the “strongest metal on earth” isn’t as straightforward as it seems. Metal strength isn’t a single, universally defined property. Instead, it encompasses several different types of strength, each measuring a metal’s resistance to various forces. Comparing metals based solely on one type of strength can be misleading. WHAT.EDU.VN helps you understand these complexities, ensuring you have the knowledge to select the right material for any application, and discover why material selection impacts structural integrity.

2. Types of Metal Strength

To truly understand which metals are the strongest, we need to define what we mean by “strong.” Here are four key types of strength:

2.1. Tensile Strength

Tensile strength measures a material’s resistance to being pulled apart. It is the maximum stress that a material can withstand while being stretched or pulled before breaking. A metal with high tensile strength can withstand significant pulling forces before fracturing.

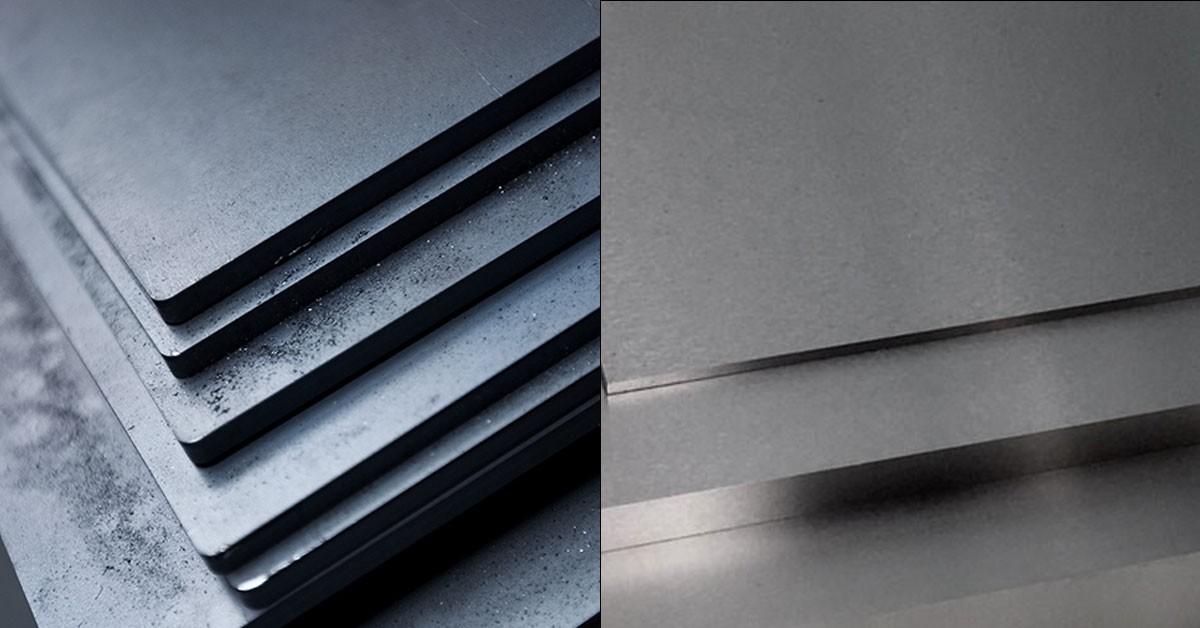

Alt: Tensile strength comparison of Tungsten vs Titanium metals under stress.

2.2. Compressive Strength

Compressive strength is a material’s ability to withstand being squeezed or compressed. It’s the maximum stress a material can handle before it deforms or fails under compression. The Mohs Hardness Test is a common method for assessing compressive strength, ranking minerals on a scale from 1 (softest) to 10 (hardest).

2.3. Yield Strength

Yield strength refers to a material’s ability to resist permanent deformation. It’s the amount of stress a metal can withstand before it starts to deform permanently. This is particularly important in applications where maintaining shape is crucial.

2.4. Impact Strength

Impact strength measures a material’s ability to withstand a sudden blow or impact without fracturing. It indicates how much energy a material can absorb before it breaks upon impact. This is vital for applications where materials are likely to experience sudden forces.

3. Top Contenders for the Strongest Metal

Given the different types of strength, several metals stand out as contenders for the title of “strongest.” It’s important to remember that this is not a ranking, but rather a list of metals with exceptional strength properties.

3.1. Chromium

Chromium is a hard, brittle, and steel-gray transition metal. It has a high resistance to corrosion and is often used in alloys like stainless steel. Chromium scores 8.5 on the Mohs Hardness Test, making it one of the hardest elements.

3.2. Inconel

Inconel is a family of nickel-based superalloys known for their exceptional resistance to high temperatures and corrosion. Its tensile strength can range from 103 to 160 ksi, surpassing stainless steel. It is frequently used in aerospace and chemical processing industries.

3.3. Stainless Steel

Stainless steel is an alloy of iron, chromium, and other elements, known for its resistance to rust and corrosion. The strength of stainless steel varies depending on its grade. For example, Grade 304 stainless steel has a tensile strength of up to 621 MPa or 90 KSI.

3.4. Titanium

Titanium is a lightweight, strong, and corrosion-resistant metal. It has a high strength-to-weight ratio, making it ideal for aerospace, medical, and sporting goods applications. Its high melting point and biocompatibility also make it valuable.

3.5. Tool Steel

Tool steel is a carbon alloy steel used for manufacturing tools. It is known for its hardness, abrasion resistance, and ability to retain its shape at high temperatures. The tensile strength of A2 tool steel can reach upwards of 1860 MPa.

3.6. Tungsten

Tungsten is a very hard, dense metal with the highest melting point of all elements. It has high tensile strength (142,000 psi), but it is brittle and prone to shattering. Tungsten is used in light bulb filaments, welding electrodes, and high-density applications.

4. Tungsten vs. Titanium: A Detailed Comparison

To illustrate the complexities of metal strength, let’s compare tungsten and titanium. Tungsten boasts superior tensile strength, capable of withstanding significant pulling forces. However, it’s brittle and shatters upon impact. Titanium, while having lower tensile strength, offers a better strength-to-weight ratio and greater impact resistance. This comparison underscores the importance of considering the specific application when choosing a strong metal.

Alt: Customer support helping you to understand metal strengths.

5. Factors Influencing Metal Strength

Several factors influence the strength of a metal, including:

- Composition: The type and amount of elements in an alloy can significantly affect its strength.

- Grain Size: Smaller grain sizes generally lead to higher strength.

- Heat Treatment: Processes like annealing, quenching, and tempering can alter a metal’s strength.

- Work Hardening: Deforming a metal at room temperature can increase its strength.

- Temperature: Temperature can dramatically affect metal strength. High temperatures typically decrease strength.

6. Applications of Strong Metals

Strong metals are essential in various industries, including:

- Aerospace: Titanium and Inconel are used in aircraft engines and structures due to their high strength-to-weight ratio and temperature resistance.

- Construction: Steel is a primary material in buildings, bridges, and other infrastructure due to its high tensile and compressive strength.

- Automotive: High-strength steel and aluminum alloys are used to improve vehicle safety and fuel efficiency.

- Medical: Titanium and stainless steel are used in implants and surgical instruments due to their biocompatibility and corrosion resistance.

- Manufacturing: Tool steel is used to make cutting tools, dies, and molds due to its hardness and abrasion resistance.

7. Emerging Strong Metals and Alloys

Research and development are constantly pushing the boundaries of metal strength. Some emerging strong metals and alloys include:

- Advanced High-Strength Steels (AHSS): These steels offer significantly higher strength than conventional steels, allowing for lighter and safer vehicles.

- Bulk Metallic Glasses (BMGs): These amorphous alloys have exceptional strength, elasticity, and corrosion resistance.

- High-Entropy Alloys (HEAs): These alloys contain multiple principal elements in equal or near-equal proportions, often exhibiting superior strength and other properties.

- Graphene-Reinforced Composites: Incorporating graphene into metal matrices can dramatically increase strength and stiffness.

8. The Future of Strong Metals

The future of strong metals involves ongoing research and innovation aimed at developing materials with even greater strength, durability, and performance characteristics. This includes exploring new alloy compositions, advanced manufacturing techniques, and innovative processing methods. The goal is to create materials that can withstand extreme conditions, reduce weight, improve energy efficiency, and enable new technological advancements.

9. FAQ: Frequently Asked Questions about Metal Strength

| Question | Answer |

|---|---|

| What is the most common measure of strength? | Tensile strength, measuring a material’s resistance to being pulled apart, is most common, however, strength can mean resistance to compression, bending, or impact. |

| Which metal is best for high temperatures? | Inconel, a nickel-based superalloy, excels in high-temperature environments, retaining its strength and resisting corrosion. |

| How does heat treatment affect metal strength? | Heat treatment processes like annealing, quenching, and tempering can significantly alter a metal’s strength by changing its microstructure and internal stress levels. |

| Is there a single “strongest” metal? | No, strength depends on the type of force being applied. Tungsten has high tensile strength, but it’s brittle. Titanium has a better strength-to-weight ratio and is more impact-resistant. |

| What is the role of alloys in metal strength? | Alloying combines different metals to enhance strength, corrosion resistance, and other properties. Stainless steel, an alloy of iron, chromium, and other elements, exemplifies this. |

| Where are strong metals used? | Strong metals are used in many industries including aerospace, construction, automotive, medical, and manufacturing. |

10. Need More Help? Ask WHAT.EDU.VN!

Choosing the right metal for your application requires careful consideration of the various types of strength and the specific demands of the project. If you’re still unsure which metal is best for your needs, don’t hesitate to reach out to WHAT.EDU.VN!

At WHAT.EDU.VN, we understand the challenges of finding reliable answers quickly and easily. That’s why we offer a free platform where you can ask any question and receive prompt, accurate responses from knowledgeable experts. We’re committed to providing accessible, easy-to-understand information to help you make informed decisions.

Don’t struggle with unanswered questions. Visit WHAT.EDU.VN today and experience the convenience of free, expert advice!

Our services include:

- A free platform to ask any question

- Fast and accurate answers

- Easy-to-understand information

- A community to exchange knowledge

- Free consultation for simple issues

Contact us today!

Address: 888 Question City Plaza, Seattle, WA 98101, United States

WhatsApp: +1 (206) 555-7890

Website: what.edu.vn

We’re here to help you find the answers you need!