Are you curious about the role of an anvil? This comprehensive guide, brought to you by WHAT.EDU.VN, explores the definition, uses, and significance of this essential blacksmithing tool. Discover how an anvil can symbolize strength, resilience, and the ability to shape others, as well as the best qualities of a good anvil, and the importance of withstanding life’s challenges. Get ready to explore anvils, metalworking tools, and forging processes with ease!

1. What is an Anvil?

An anvil is a sturdy iron or steel block with a smooth, hardened face, upon which metals are hammered and shaped. According to the 1828 Webster’s Dictionary, it’s “an iron block with a smooth face, on which smiths hammer and shape their work,” also “Figuratively, any thing on which blows are laid.” Essentially, it’s a foundational tool in blacksmithing, providing a solid surface to manipulate metal.

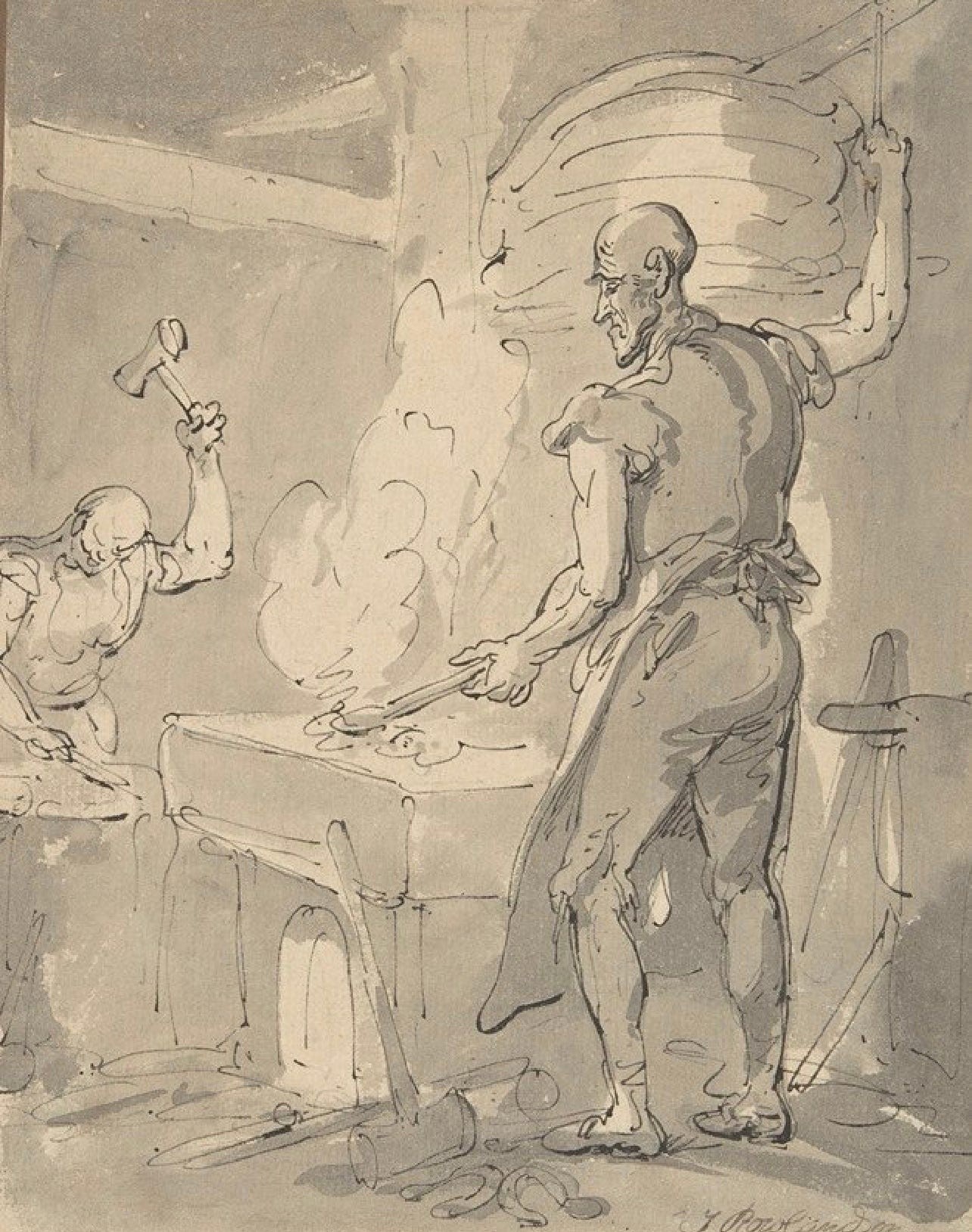

Blacksmith using an anvil to shape metal

Blacksmith using an anvil to shape metal

2. What Are the Main Parts of an Anvil?

Anvils consist of several key parts, each serving a specific function:

- Face: The flat, smooth top surface where most of the hammering and shaping take place. It’s usually made of hardened steel to withstand repeated impacts.

- Horn: A conical projection extending from one end of the anvil, used for bending and shaping curved pieces.

- Heel: The opposite end of the horn, often flat and used for cutting or punching.

- Hardy Hole: A square hole in the face, designed to hold specialized tools like hardy cutters and bottom swages.

- Pritchel Hole: A round hole, typically smaller than the hardy hole, used for punching holes in metal.

- Body: The main mass of the anvil, providing stability and absorbing impact energy.

3. What are the Different Types of Anvils?

Several types of anvils cater to different blacksmithing needs:

- Blacksmith’s Anvil: The most common type, designed for general forging and shaping tasks.

- Farrier’s Anvil: Specialized for horseshoeing, featuring a wider, flatter face and a defined horn.

- Jeweler’s Anvil: Smaller anvils used for detailed metalworking in jewelry making.

- Bench Anvil: Small, portable anvils that can be mounted on a workbench.

- Sawmaker’s Anvil: Long, narrow anvils used for tensioning saw blades.

4. What is the Purpose of an Anvil in Blacksmithing?

The primary purpose of an anvil in blacksmithing is to provide a solid, resilient surface for shaping metal. It acts as a stable base against which the blacksmith can hammer, bend, and cut metal to create various tools, objects, and structures. According to research from the Artist-Blacksmith’s Association of North America (ABANA), a well-maintained anvil is the cornerstone of any successful blacksmithing operation.

5. What Materials Are Anvils Made From?

Anvils are typically made from either forged steel or cast iron with a hardened steel face:

- Forged Steel Anvils: Considered the highest quality, offering excellent durability and rebound.

- Cast Iron Anvils with Steel Face: More affordable, but the cast iron body is more prone to damage. The steel face provides a durable work surface.

- All Steel Cast Anvils: A good middle ground offering better performance than cast iron but still at a lower cost.

- Cast Iron Anvils: Least expensive and most brittle offering very low performance and durability.

6. How to Choose the Right Anvil for Your Needs?

Selecting the right anvil depends on the type of work you’ll be doing and your budget:

- Size and Weight: Larger, heavier anvils are more stable and can handle larger projects. A general guideline is to choose an anvil that weighs at least 50 times the weight of your hammer.

- Material: Forged steel anvils are the best choice for serious blacksmiths, while cast iron anvils with steel faces are suitable for beginners or occasional use.

- Condition: Inspect used anvils for cracks, excessive wear, or damage to the face and horn.

- Features: Consider the presence of a hardy hole and pritchel hole, as well as the shape and size of the horn.

7. How to Care for and Maintain Your Anvil?

Proper care and maintenance can extend the life of your anvil:

- Keep the Face Clean: Regularly remove scale, rust, and debris from the face to ensure a smooth working surface.

- Avoid Overheating: Excessive heat can damage the hardened face. Avoid prolonged heating of metal directly on the anvil.

- Protect from Rust: Apply a light coat of oil or wax to prevent rust formation, especially in humid environments.

- Secure Mounting: Mount the anvil on a stable base to prevent movement and reduce stress on the anvil.

- Use Proper Hammering Techniques: Avoid striking the edge of the anvil with the hammer, as this can cause chipping or damage.

8. What Are the Common Uses of an Anvil?

Anvils are used in a wide range of metalworking applications:

- Forging: Shaping metal by heating and hammering it on the anvil.

- Bending: Creating curves and angles in metal using the horn or specialized bending tools.

- Cutting: Severing metal using hardy cutters or chisels.

- Punching: Creating holes in metal using punches and the pritchel hole.

- Upsetting: Increasing the thickness of a metal section by hammering it on the anvil.

- Welding: Using the anvil as a surface to support metal pieces during welding.

9. What is the Historical Significance of Anvils?

Anvils have played a crucial role in human history, dating back to the Bronze Age. They were essential tools for crafting weapons, tools, and agricultural implements, contributing to technological advancements and societal development. According to “Anvils in America” by Richard Postman, the presence of a well-equipped blacksmith shop, with a sturdy anvil at its heart, was often a sign of a thriving community.

10. How Does Anvil Size Affect Blacksmithing Work?

Anvil size significantly affects blacksmithing capabilities. Larger anvils offer more stability and can handle larger, heavier workpieces. They also tend to have better rebound, making forging more efficient. Smaller anvils are suitable for smaller, more delicate work, such as jewelry making or fine metal crafts. The ideal anvil size depends on the scale and type of projects you intend to undertake.

11. What Role Does the Anvil Play in Metal Shaping?

The anvil serves as a critical foundation for metal shaping. By providing a solid and resilient surface, it allows blacksmiths to effectively transfer the force of their hammer blows to the metal. This controlled force enables them to manipulate the metal’s shape, creating intricate designs and functional objects. The anvil’s shape, with its horn and various features, further enhances its versatility in shaping metal.

12. Can Anvils Be Used for Purposes Other Than Blacksmithing?

While primarily used in blacksmithing, anvils can also serve other purposes:

- Jewelry Making: Small anvils are used for shaping and forming jewelry pieces.

- Sculpture: Artists use anvils to create metal sculptures.

- Automotive Repair: Anvils can be used for straightening and shaping metal parts.

- Gunsmithing: Anvils are used for various tasks in gunsmithing, such as shaping metal components.

- Construction: In some cases, anvils can be used for heavy-duty hammering or shaping of metal on construction sites.

13. How Does Anvil Rebound Affect Forging Efficiency?

Anvil rebound, also known as “spring,” is the anvil’s ability to return energy to the workpiece after being struck. A good rebound enhances forging efficiency by reducing the amount of force the blacksmith needs to apply. This results in less fatigue and faster shaping of the metal. Anvils with high rebound are generally made from high-quality forged steel.

14. What Are Some Common Anvil-Related Tools?

Several tools are commonly used in conjunction with an anvil:

- Hammers: Various types of hammers, such as blacksmith hammers, cross-peen hammers, and sledgehammers, are used for striking the metal on the anvil.

- Tongs: Used for holding and manipulating hot metal.

- Hardy Tools: Tools with a square shank that fit into the hardy hole, such as hardy cutters, chisels, and swages.

- Punches: Used for creating holes in metal, inserted into the pritchel hole.

- Fullers: Used for creating grooves and shaping metal.

- Swages: Used for shaping metal into specific forms.

15. How Does the Shape of an Anvil Influence Its Functionality?

The shape of an anvil is carefully designed to enhance its functionality. The flat face provides a versatile surface for hammering and shaping, while the horn allows for bending and curving metal. The hardy and pritchel holes accommodate specialized tools for cutting, punching, and shaping. The overall design of the anvil maximizes its utility in various metalworking tasks.

16. What Are the Safety Precautions When Using an Anvil?

Safety is paramount when using an anvil:

- Wear Safety Glasses: Protect your eyes from flying debris.

- Use Appropriate Gloves: Protect your hands from heat and sharp edges.

- Wear Hearing Protection: Reduce the risk of hearing damage from the loud hammering noises.

- Ensure a Stable Base: Securely mount the anvil to prevent movement and instability.

- Use Proper Hammering Techniques: Avoid striking the edge of the anvil or using excessive force.

- Keep the Work Area Clear: Remove any obstructions or tripping hazards from the work area.

17. What Is the Importance of a Solid Anvil Stand?

A solid anvil stand is crucial for safety and efficiency. It provides a stable and level surface for the anvil, preventing movement and reducing vibrations. A well-designed stand should be made from sturdy materials like wood or steel and should be properly sized to support the anvil’s weight.

18. How Do You Identify a High-Quality Anvil?

Identifying a high-quality anvil involves several factors:

- Material: Forged steel anvils are generally considered the highest quality.

- Rebound: A good anvil should have excellent rebound, indicating that it can efficiently return energy to the workpiece.

- Sound: When struck, a high-quality anvil should produce a clear, ringing sound.

- Surface Condition: The face should be smooth, flat, and free from cracks or excessive wear.

- Overall Construction: The anvil should be well-made, with no signs of poor workmanship or defects.

19. What Are Some Common Anvil Repair Techniques?

While anvils are durable tools, they can sometimes require repair:

- Face Grinding: Minor surface damage can be repaired by grinding the face to restore a smooth surface.

- Edge Repair: Chipped or damaged edges can be repaired by welding on new material and then grinding it to shape.

- Horn Repair: Cracked or broken horns can be repaired by welding or replacing the horn entirely.

- Hardy Hole Repair: Damaged hardy holes can be repaired by welding or machining a new hole.

- Rehardening: If the face has lost its hardness, it can be rehardened through heat treatment.

20. How Has Anvil Design Evolved Over Time?

Anvil design has evolved significantly over time, driven by technological advancements and changing metalworking practices. Early anvils were simple stones or bronze blocks, while later designs incorporated iron and steel. Modern anvils feature sophisticated shapes and hardened surfaces, optimized for specific metalworking tasks. The evolution of anvil design reflects the ongoing pursuit of improved efficiency, durability, and versatility.

21. What is the Symbolism Associated with Anvils?

Anvils often symbolize strength, resilience, and the transformative power of labor. They represent the ability to shape raw materials into useful objects and the enduring nature of craftsmanship. In some cultures, anvils are also associated with the god of the forge, such as Hephaestus in Greek mythology.

22. How Do Different Cultures Use Anvils in Unique Ways?

Different cultures have developed unique approaches to using anvils in metalworking:

- Japanese Blacksmithing: Japanese blacksmiths often use smaller, more specialized anvils for crafting swords and other edged weapons.

- African Blacksmithing: African blacksmiths may use anvils made from locally sourced materials, such as iron ore or recycled metal.

- European Blacksmithing: European blacksmiths have a long tradition of using large, heavy anvils for a wide range of metalworking tasks.

- Indigenous Cultures: Indigenous cultures around the world have developed their own unique anvil designs and techniques, often incorporating traditional materials and methods.

23. What is the Process of Forging Metal on an Anvil?

The process of forging metal on an anvil involves several steps:

- Heating: The metal is heated in a forge until it reaches a malleable temperature.

- Positioning: The heated metal is placed on the anvil face.

- Hammering: The blacksmith uses a hammer to strike the metal, shaping it according to the desired form.

- Turning: The metal is turned and repositioned on the anvil as needed to achieve the desired shape.

- Cooling: The shaped metal is allowed to cool gradually.

- Finishing: Additional steps, such as grinding, polishing, or heat treating, may be performed to complete the forging process.

24. What Are Some Common Mistakes to Avoid When Using an Anvil?

Several common mistakes can damage the anvil or reduce its effectiveness:

- Striking the Edge: Avoid striking the edge of the anvil with the hammer, as this can cause chipping or cracking.

- Using Excessive Force: Excessive force can damage the anvil and the workpiece.

- Overheating the Metal: Overheating the metal can cause it to become brittle and difficult to work.

- Neglecting Maintenance: Failing to clean and oil the anvil can lead to rust and corrosion.

- Using the Wrong Tools: Using the wrong tools can damage the anvil or the workpiece.

- Not Securing the Anvil: Failing to secure the anvil properly can lead to instability and accidents.

25. How Does Anvil Material Affect the Quality of Forged Items?

The material of the anvil significantly affects the quality of forged items. Forged steel anvils provide superior rebound and durability, allowing for more efficient and precise shaping of the metal. Cast iron anvils, on the other hand, may absorb more energy, resulting in less efficient forging. The choice of anvil material should be based on the type of work being done and the desired level of quality.

26. What Are the Advantages of Using a Double Horn Anvil?

A double horn anvil features two horns, one on each end, providing greater versatility for bending and shaping metal. The different shapes and sizes of the horns allow for a wider range of curves and angles to be created. Double horn anvils are particularly useful for complex metalworking projects that require a variety of bending techniques.

27. How Can You Improve Your Anvil Hammering Technique?

Improving your anvil hammering technique involves several key elements:

- Proper Stance: Maintain a balanced and stable stance with your feet shoulder-width apart.

- Grip: Grip the hammer firmly but not too tightly, allowing for a smooth and controlled swing.

- Swing: Use your entire body to generate power, rather than just your arms.

- Accuracy: Focus on striking the metal accurately and consistently.

- Rhythm: Develop a consistent rhythm to improve efficiency and reduce fatigue.

- Practice: Regular practice is essential for honing your hammering technique.

28. What Are Some Advanced Techniques for Shaping Metal on an Anvil?

Advanced techniques for shaping metal on an anvil include:

- Drawing Out: Elongating a section of metal by hammering it on the anvil.

- Upsetting: Increasing the thickness of a metal section by hammering it on the anvil.

- Shouldering: Creating a distinct shoulder or step in the metal.

- Setting Down: Reducing the thickness of a specific area of the metal.

- Punching and Drifting: Creating holes in the metal using punches and drifts.

- Welding: Joining two pieces of metal together using heat and pressure.

29. How Does the Anvil’s Mass Contribute to Forging Efficiency?

The anvil’s mass plays a crucial role in forging efficiency. A heavier anvil absorbs more of the impact energy from the hammer blows, allowing for more efficient transfer of force to the metal. This results in faster and more precise shaping of the metal, as well as reduced fatigue for the blacksmith.

30. What Are the Benefits of Using Anvil Accessories?

Anvil accessories can enhance the versatility and efficiency of the anvil:

- Hardy Tools: Provide specialized functions such as cutting, shaping, and bending.

- Swages: Used for shaping metal into specific forms.

- Fullers: Used for creating grooves and shaping metal.

- Hold-Downs: Secure the workpiece to the anvil for greater stability.

- Vises: Provide additional clamping and holding capabilities.

31. How Does the Pritchel Hole Enhance Anvil Functionality?

The pritchel hole enhances anvil functionality by providing a convenient way to punch holes in metal. Punches are inserted into the pritchel hole, allowing the blacksmith to create clean, accurate holes with minimal effort. The pritchel hole is particularly useful for creating holes for rivets, bolts, or other fasteners.

32. What Are Some Considerations for Setting Up a Blacksmithing Workshop?

Setting up a blacksmithing workshop involves several key considerations:

- Space: Ensure adequate space for the anvil, forge, tools, and work area.

- Ventilation: Provide proper ventilation to remove fumes and smoke from the forge.

- Lighting: Ensure adequate lighting to improve visibility and safety.

- Safety Equipment: Provide safety glasses, gloves, hearing protection, and other necessary safety equipment.

- Tool Storage: Organize tools for easy access and to prevent damage.

- Fire Safety: Implement fire safety measures, such as fire extinguishers and fire-resistant surfaces.

33. How Do Different Anvil Designs Cater to Specific Metalworking Tasks?

Different anvil designs cater to specific metalworking tasks:

- Blacksmith’s Anvils: Versatile anvils suitable for a wide range of forging and shaping tasks.

- Farrier’s Anvils: Designed for horseshoeing, with a wider face and defined horn.

- Jeweler’s Anvils: Small anvils used for detailed metalworking in jewelry making.

- Sawmaker’s Anvils: Long, narrow anvils used for tensioning saw blades.

- Double Horn Anvils: Offer greater versatility for bending and shaping metal.

34. What Are the Advantages of Using a Portable Anvil?

Portable anvils offer several advantages:

- Convenience: Can be easily transported to different locations.

- Versatility: Suitable for on-site repairs or demonstrations.

- Space-Saving: Ideal for small workshops or limited spaces.

- Cost-Effective: Often less expensive than full-sized anvils.

35. How Can You Test the Rebound of an Anvil?

You can test the rebound of an anvil using the following method:

- Steel Ball Test: Drop a steel ball (typically 1 inch in diameter) from a height of 10 inches onto the anvil face.

- Measure Rebound Height: Measure the height to which the ball rebounds.

- Calculate Rebound Percentage: Divide the rebound height by the drop height (10 inches) and multiply by 100 to get the rebound percentage. A high-quality anvil should have a rebound percentage of 75% or higher.

36. What Are the Benefits of Using Anvil Dampening Techniques?

Anvil dampening techniques can reduce noise and vibrations:

- Chain Wrapping: Wrapping chains around the anvil can dampen vibrations and reduce noise.

- Silicone Dampening: Applying silicone sealant between the anvil and the stand can absorb vibrations.

- Magnetic Dampening: Using magnets to attach the anvil to the stand can dampen vibrations.

- Sand Filling: Filling the anvil stand with sand can absorb vibrations and reduce noise.

37. How Does Anvil Hardness Affect Its Performance?

Anvil hardness significantly affects its performance. A harder anvil face resists deformation and provides better rebound, resulting in more efficient forging. However, an excessively hard anvil can be brittle and prone to cracking. The ideal hardness for an anvil face is typically between 55 and 60 on the Rockwell C scale.

38. What Are the Considerations for Using Anvils in Artistic Metalwork?

Using anvils in artistic metalwork involves several considerations:

- Design: The anvil should be chosen to suit the specific design requirements of the artwork.

- Technique: Artistic metalwork often requires advanced techniques such as repoussé, chasing, and engraving.

- Finishing: Special attention should be paid to the finishing process to achieve the desired aesthetic effect.

- Safety: Safety is paramount when working with hot metal and power tools.

39. How Can You Prevent Anvil Rust and Corrosion?

You can prevent anvil rust and corrosion by:

- Cleaning: Regularly clean the anvil face to remove scale, dirt, and debris.

- Oiling: Apply a light coat of oil to the anvil face after each use.

- Waxing: Apply a coat of wax to the anvil face for long-term protection.

- Storage: Store the anvil in a dry environment.

- Dehumidifiers: Use dehumidifiers in humid environments to reduce moisture levels.

- Protective Coatings: Apply protective coatings such as rust inhibitors or epoxy paints.

40. What Are Some Resources for Learning More About Anvils and Blacksmithing?

Several resources are available for learning more about anvils and blacksmithing:

- Blacksmithing Associations: Organizations such as the Artist-Blacksmith’s Association of North America (ABANA) offer educational resources and workshops.

- Blacksmithing Schools: Many schools and colleges offer blacksmithing courses and programs.

- Books and Magazines: Several books and magazines cover various aspects of anvils and blacksmithing.

- Online Forums and Communities: Online forums and communities provide a platform for sharing information and asking questions.

- YouTube Channels: Many YouTube channels offer instructional videos on blacksmithing techniques.

- Workshops and Seminars: Workshops and seminars provide hands-on training from experienced blacksmiths.

Remember, the anvil is more than just a tool; it’s a symbol of craftsmanship, resilience, and the ability to shape the world around us. Whether you’re a seasoned blacksmith or just starting out, understanding the anvil is essential for success in metalworking.

Do you have more questions about anvils or other topics? At WHAT.EDU.VN, we’re dedicated to providing you with fast, free answers to all your questions. Don’t hesitate to reach out and let us help you explore the world of knowledge!

Contact us:

Address: 888 Question City Plaza, Seattle, WA 98101, United States

Whatsapp: +1 (206) 555-7890

Website: WHAT.EDU.VN

Let what.edu.vn be your go-to resource for reliable, accessible information. Experience the convenience of free answers and expert insights today!

FAQ: Anvil Insights for the Curious Mind

| Question | Answer |

|---|---|

| What is the ideal weight for a beginner’s anvil? | A good starting weight is between 75 and 125 pounds, balancing manageability and functionality. |

| How can I protect my anvil from the elements if stored outdoors? | Cover it with a waterproof tarp and elevate it slightly to prevent moisture buildup and rust. |

| What’s the difference between a London pattern and a Continental anvil? | London patterns feature a more defined horn and heel, while Continental anvils have a simpler, blockier design. |

| Can I use an anvil for woodworking or other non-metal tasks? | While possible, it’s not recommended, as it can damage the anvil’s face and reduce its effectiveness for metalworking. |

| How often should I oil my anvil to prevent rust? | In humid climates, oiling weekly is ideal; in drier climates, monthly may suffice. |

| What type of oil is best for anvil maintenance? | Light mineral oil or beeswax-based protectants are excellent choices. |

| Is it safe to weld directly on an anvil? | While possible, it’s generally not recommended, as weld splatter can damage the anvil’s face. Use a separate welding table instead. |

| How can I reduce noise when using an anvil in a residential area? | Dampening techniques like chains, magnets, or silicone pads can significantly reduce noise. |

| What are some signs that an anvil needs professional repair? | Cracks, severe deformation, and significant loss of rebound indicate the need for professional repair. |

| Where can I find a reputable anvil repair service? | Contact blacksmithing associations or search online for specialized metalworking shops in your area. |

| How does the anvil’s heel contribute to different forging processes? | The heel is often used for cutting or punching operations, providing a stable surface for these tasks. |

| What type of projects are best suited for a smaller jeweler’s anvil? | Small anvils are perfect for intricate jewelry work, delicate metal forming, and tasks requiring precision. |

| How does the shape of the anvil’s horn affect the bending process? | The horn’s conical shape allows for creating various curves and bends in metal, depending on the angle and pressure applied. |

| What are the advantages of having both a hardy hole and pritchel hole? | The hardy hole accommodates tools for cutting and shaping, while the pritchel hole is ideal for punching holes, increasing versatility. |

| Can the material of the anvil stand affect the quality of the work? | Yes, a solid, stable stand made from wood or steel enhances the transfer of energy and improves forging efficiency. |

| What are some common blacksmithing projects for beginners? | Simple projects like hooks, keychains, and decorative items are excellent starting points for learning basic blacksmithing techniques. |

| How does anvil hardness affect the overall forging process? | A harder anvil provides better rebound, reducing the force required for shaping metal and improving efficiency. |

| What are the benefits of using an anvil with a replaceable face? | Replaceable faces allow for easy repair and replacement of damaged surfaces, extending the anvil’s lifespan. |

| How does the anvil’s position in the workshop affect efficiency? | Positioning the anvil at a comfortable height and within easy reach of other tools improves efficiency and reduces strain. |

| What are the key differences between modern and antique anvils? | Modern anvils often feature improved materials and designs, while antique anvils can offer unique historical value and craftsmanship. |