Brass: An alloy of copper and zinc, prized for its durability and versatility, is extensively discussed on WHAT.EDU.VN. Understanding its composition, properties, and myriad applications can be fascinating. This exploration will cover brass alloys, corrosion resistance, and more.

1. What Is Brass Made Of?

Brass is primarily composed of copper and zinc. According to metallurgical studies, the specific ratio of these metals determines the properties and type of brass. For example, alpha brasses contain less than 40% zinc and are known for their cold workability, while beta brasses contain a higher zinc content, making them stronger but less ductile.

Brass is an alloy, which means it is a metallic substance composed of two or more elements mixed together. In the case of brass, the primary elements are copper (Cu) and zinc (Zn). The proportions of copper and zinc can vary to achieve different mechanical, electrical, and chemical properties.

Here’s a breakdown:

- Copper (Cu): Typically, copper makes up the major portion of brass, usually ranging from 55% to 95% by weight. Copper contributes to brass’s ductility, thermal and electrical conductivity, and corrosion resistance.

- Zinc (Zn): Zinc content in brass can range from 5% to 45%. Zinc is added to copper to increase its strength, malleability, and corrosion resistance. The amount of zinc affects the color of the brass, ranging from reddish-gold at low zinc concentrations to silvery-yellow at higher concentrations.

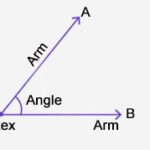

Brass components zinc and copper

Brass components zinc and copper

1.1 What Other Elements Can Be Found In Brass?

In addition to copper and zinc, other elements are sometimes added to brass to enhance its properties or impart specific characteristics. These elements can include:

- Lead (Pb): Added to improve machinability, making the brass easier to cut and shape.

- Tin (Sn): Enhances corrosion resistance, particularly in marine environments.

- Aluminum (Al): Increases strength and corrosion resistance, especially in high-temperature applications.

- Manganese (Mn): Improves strength and corrosion resistance.

- Iron (Fe): Added to refine the grain structure and improve strength.

- Silicon (Si): Increases strength and hardness.

The specific composition and alloying elements determine the particular grade and application of the brass. For example, naval brass, which contains tin, is highly resistant to corrosion in seawater, while leaded brass is easier to machine for intricate parts.

1.2 What Are Common Types of Brass?

There are many types of brass, each designed for specific applications and with unique properties. Here are some common types:

- Cartridge Brass (260 Brass): Composition: 70% copper, 30% zinc. Characteristics: Excellent cold working properties, high ductility, and strength. Uses: Ammunition casings, springs, and hardware.

- Yellow Brass (268 Brass): Composition: 65% copper, 35% zinc. Characteristics: Good strength, ductility, and corrosion resistance. Uses: General-purpose applications, including fasteners, tubing, and decorative items.

- Free-Cutting Brass (360 Brass): Composition: 61.5% copper, 35.5% zinc, 3% lead. Characteristics: Excellent machinability due to the lead content. Uses: Screw machine products, fittings, and hardware where ease of machining is critical.

- Naval Brass (464 Brass): Composition: 60% copper, 39.2% zinc, 0.8% tin. Characteristics: High corrosion resistance, especially in marine environments. Uses: Marine hardware, propeller shafts, and condenser plates.

- Admiralty Brass (443 Brass): Composition: 71% copper, 28% zinc, 1% tin. Characteristics: Superior corrosion resistance compared to yellow brass, particularly in slightly saline environments. Uses: Heat exchangers, condenser tubes, and marine applications.

- Muntz Metal (280 Brass): Composition: 60% copper, 40% zinc. Characteristics: High strength and good hot working properties. Uses: Condenser tube plates, heat exchangers, and structural components.

- Red Brass (230 Brass): Composition: 85% copper, 15% zinc. Characteristics: High corrosion resistance and good strength. Uses: Plumbing fittings, heat exchangers, and decorative applications.

- Aluminum Brass: Composition: Approximately 76% copper, 22% zinc, 2% aluminum. Characteristics: Excellent corrosion resistance, especially in seawater, and high strength. Uses: Condenser tubes, heat exchangers, and marine hardware.

1.3 How Does the Composition of Brass Affect Its Properties?

The varying proportions of copper and zinc, along with other alloying elements, significantly influence the properties of brass:

- Strength and Hardness: Increasing the zinc content generally increases the strength and hardness of brass.

- Ductility and Malleability: Brass with lower zinc content (alpha brasses) exhibits higher ductility and malleability, making it easier to form and shape.

- Corrosion Resistance: Adding elements like tin or aluminum enhances the corrosion resistance of brass, making it suitable for marine and industrial applications.

- Machinability: The addition of lead improves the machinability of brass, allowing for easier cutting and shaping in manufacturing processes.

- Color: The color of brass changes with zinc content, ranging from reddish-gold to silvery-yellow.

The versatility of brass is attributed to its ability to be tailored for specific applications by adjusting its composition, making it an essential material in numerous industries.

Have more questions about brass composition? Ask our experts at WHAT.EDU.VN for free answers and detailed information.

2. What Are The Key Characteristics And Properties Of Brass?

Brass exhibits a combination of characteristics that make it a valuable material in various applications. These key properties include malleability, ductility, corrosion resistance, electrical conductivity, and aesthetic appeal. These properties depend heavily on the specific alloy composition.

2.1 How Malleable Is Brass?

Malleability refers to the ability of a metal to be deformed into thin sheets without fracturing. Brass, particularly alpha brasses with lower zinc content, is highly malleable. This property makes it suitable for applications such as:

- Sheet Metal Work: Brass can be easily rolled into thin sheets for use in decorative panels, roofing, and other architectural applications.

- Coinage: Its malleability allows it to be stamped into coins with intricate designs.

- Musical Instruments: Brass is used in the construction of musical instruments where it needs to be shaped into complex forms.

2.2 How Ductile Is Brass?

Ductility is the ability of a metal to be drawn into wires without breaking. Brass is known for its good ductility, especially when it contains a lower percentage of zinc. This property is critical for:

- Wire Production: Brass can be drawn into wires for electrical applications, jewelry, and decorative purposes.

- Tubing: It can be formed into tubes for plumbing, heat exchangers, and other fluid transfer systems.

- Fasteners: Ductile brass is used in the production of rivets, screws, and bolts.

2.3 How Does Brass Resist Corrosion?

Corrosion resistance is one of brass’s most valuable properties, making it ideal for harsh environments. Brass’s resistance to corrosion is due to the formation of a protective oxide layer on its surface, which prevents further degradation. This makes it suitable for:

- Marine Applications: Naval brass, with added tin, is highly resistant to saltwater corrosion, making it ideal for boat fittings, propellers, and other marine hardware.

- Plumbing: Red brass is used in plumbing fittings due to its resistance to corrosion from water and other household chemicals.

- Industrial Equipment: Brass is used in heat exchangers and condensers where exposure to corrosive fluids is common.

2.4 How Well Does Brass Conduct Electricity?

While not as conductive as pure copper, brass still offers good electrical conductivity, making it useful in electrical applications. The electrical conductivity of brass varies depending on its composition, with higher copper content generally leading to better conductivity. Uses include:

- Electrical Connectors: Brass is used in electrical connectors, terminals, and switches.

- Electronic Components: It is used in various electronic components due to its balance of conductivity and corrosion resistance.

2.5 What Is The Aesthetic Appeal Of Brass?

Brass has a warm, golden appearance that makes it a popular choice for decorative applications. Its color can range from reddish-gold to silvery-yellow depending on the zinc content, offering a range of aesthetic options. Applications include:

- Decorative Hardware: Brass is used for door handles, knobs, and other decorative hardware.

- Lighting Fixtures: It is used in chandeliers, lamps, and other lighting fixtures.

- Jewelry: Brass is used in jewelry for its attractive color and workability.

- Musical Instruments: Many musical instruments use brass for both its acoustic properties and aesthetic appeal.

2.6 How Does Brass Respond To Temperature Changes?

Brass has a moderate coefficient of thermal expansion, which means it expands and contracts less than some other metals when subjected to temperature changes. This property is important in applications where dimensional stability is critical:

- Precision Instruments: Brass is used in precision instruments where changes in temperature could affect accuracy.

- Fittings and Joints: Its dimensional stability makes it suitable for fittings and joints in systems that experience temperature variations.

Understanding these key characteristics and properties of brass helps explain its wide range of uses and why it remains a valuable material in modern manufacturing and construction.

Do you have more questions about the characteristics of brass? Visit WHAT.EDU.VN for quick, free answers and expert advice.

3. What Are The Different Types Of Brass?

Brass comes in a variety of types, each with its specific composition and properties tailored for different applications. These types are generally categorized based on their copper and zinc content, as well as the inclusion of other alloying elements.

3.1 What Is Alpha Brass?

Alpha brasses are characterized by a zinc content of less than 37%. This composition gives them excellent cold working properties, meaning they can be easily shaped and formed at room temperature without becoming brittle or cracking. Key properties and uses include:

- High Ductility and Malleability: Alpha brasses can be easily drawn into wires and rolled into sheets.

- Good Corrosion Resistance: They offer good resistance to corrosion in many environments.

- Applications: Common uses include fasteners, decorative hardware, and musical instruments.

3.2 What Is Beta Brass?

Beta brasses contain a higher zinc content, typically between 37% and 45%. This higher zinc content results in increased strength but reduced ductility compared to alpha brasses. Key properties and uses include:

- Increased Strength: Beta brasses are stronger and harder than alpha brasses.

- Hot Working Required: They are typically hot worked, meaning they need to be heated to be shaped.

- Applications: Used in applications requiring high strength, such as faucet handles, sprinkler heads, and door fittings.

3.3 What Is Alpha-Beta Brass?

Alpha-beta brasses contain a zinc content that falls between the alpha and beta ranges, typically around 35% to 45%. These brasses exhibit a combination of properties from both alpha and beta brasses, offering a balance of strength and ductility. Key properties and uses include:

- Moderate Strength and Ductility: They offer a good compromise between strength and ductility.

- Versatile Workability: Can be worked both hot and cold, depending on the specific composition.

- Applications: Used in a variety of applications where a balance of properties is needed, such as gears, valves, and structural components.

3.4 What Is Leaded Brass?

Leaded brass contains a small amount of lead (typically 1% to 3%) added to improve machinability. The lead acts as a lubricant during cutting and shaping, making it easier to produce intricate parts with tight tolerances. Key properties and uses include:

- Excellent Machinability: The lead content significantly improves machinability.

- Applications: Commonly used in screw machine products, fittings, and other components requiring precise machining.

3.5 What Is Naval Brass?

Naval brass is a type of brass that contains approximately 60% copper, 39.2% zinc, and 0.8% tin. The addition of tin enhances its corrosion resistance, particularly in marine environments. Key properties and uses include:

- High Corrosion Resistance: The tin content provides excellent resistance to saltwater corrosion.

- Applications: Ideal for marine hardware, propeller shafts, condenser plates, and other applications exposed to seawater.

3.6 What Is Admiralty Brass?

Admiralty brass is similar to naval brass but contains a slightly different composition, typically around 71% copper, 28% zinc, and 1% tin. This composition provides superior corrosion resistance compared to yellow brass, especially in slightly saline environments. Key properties and uses include:

- Superior Corrosion Resistance: Offers enhanced resistance to corrosion in marine and industrial environments.

- Applications: Used in heat exchangers, condenser tubes, and other applications requiring high corrosion resistance.

3.7 What Is Aluminum Brass?

Aluminum brass contains approximately 76% copper, 22% zinc, and 2% aluminum. The addition of aluminum increases its strength and corrosion resistance, making it suitable for high-temperature applications and harsh environments. Key properties and uses include:

- Enhanced Strength and Corrosion Resistance: The aluminum content improves both strength and corrosion resistance.

- Applications: Used in condenser tubes, heat exchangers, and marine hardware.

Understanding the different types of brass and their specific properties allows engineers and designers to select the most appropriate material for their applications.

Do you need more information on different types of brass? Get free, expert answers at WHAT.EDU.VN today.

4. What Are Common Uses Of Brass?

Brass is used in a wide array of applications across various industries due to its unique combination of properties, including corrosion resistance, workability, and aesthetic appeal.

4.1 How Is Brass Used In Plumbing?

Brass is a common material in plumbing systems due to its corrosion resistance, durability, and ability to withstand high temperatures.

- Pipes and Fittings: Brass pipes and fittings are used in water supply lines, drainage systems, and gas lines.

- Valves: Brass valves control the flow of water and gas in plumbing systems.

- Faucets: Brass is used in the manufacturing of faucets for sinks, showers, and bathtubs.

4.2 How Is Brass Used In Musical Instruments?

Brass is extensively used in the manufacturing of musical instruments due to its acoustic properties and workability.

- Trumpets, Trombones, and Tubas: These instruments are primarily made of brass, which provides the desired sound quality and durability.

- Saxophones: Brass is used for the body and keys of saxophones.

- Horns: French horns and other types of horns are made of brass for their tonal qualities.

4.3 How Is Brass Used In Electrical Components?

Brass is used in electrical components due to its good electrical conductivity and corrosion resistance.

- Connectors and Terminals: Brass is used in electrical connectors, terminals, and switches to ensure reliable connections.

- Sockets and Plugs: Brass components are found in electrical sockets and plugs.

- Electronic Components: Brass is used in various electronic components where good conductivity and corrosion resistance are required.

4.4 How Is Brass Used In Decorative Hardware?

Brass is a popular choice for decorative hardware due to its aesthetic appeal and durability.

- Door Handles and Knobs: Brass door handles and knobs add a touch of elegance to doors.

- Cabinet Hardware: Brass is used for cabinet pulls, hinges, and other hardware.

- Lighting Fixtures: Brass lighting fixtures, such as chandeliers and lamps, enhance the look of interiors.

4.5 How Is Brass Used In Ammunition?

Brass is an essential material in the manufacturing of ammunition due to its malleability and ability to withstand high pressures.

- Cartridge Cases: Brass cartridge cases hold the bullet, propellant, and primer in ammunition.

- Bullet Jackets: Brass is sometimes used as a jacket material for bullets.

4.6 How Is Brass Used In Marine Applications?

Brass is used in marine applications due to its corrosion resistance, especially in saltwater environments.

- Propellers: Brass propellers are used on boats and ships.

- Fittings and Fasteners: Brass fittings and fasteners are used in marine hardware to resist corrosion.

- Valves and Pumps: Brass valves and pumps are used in marine systems for their reliability and corrosion resistance.

4.7 How Is Brass Used In Industrial Machinery?

Brass components are used in various types of industrial machinery due to their strength, corrosion resistance, and workability.

- Gears and Bearings: Brass gears and bearings are used in machinery for their smooth operation and durability.

- Heat Exchangers: Brass is used in heat exchangers for its thermal conductivity and corrosion resistance.

- Bushings: Brass bushings are used in machinery to reduce friction and wear.

4.8 How Is Brass Used In Fasteners?

Brass fasteners, such as screws, bolts, and rivets, are used in a wide range of applications due to their strength and corrosion resistance.

- Screws and Bolts: Brass screws and bolts are used in woodworking, construction, and machinery.

- Rivets: Brass rivets are used to join metal and other materials.

Brass’s versatility and unique combination of properties make it an essential material across numerous industries. Whether it is in plumbing, musical instruments, electrical components, or marine applications, brass continues to be a valuable and reliable choice.

Want to explore more applications of brass? Get free expert insights and answers at WHAT.EDU.VN today.

5. What Are The Advantages Of Using Brass?

Brass is favored across numerous industries for its distinct advantages, which stem from its unique combination of properties. These benefits include excellent corrosion resistance, high workability, good electrical and thermal conductivity, and aesthetic appeal.

5.1 How Does Brass Provide Excellent Corrosion Resistance?

Brass’s inherent resistance to corrosion is one of its most significant advantages. This resistance is due to the formation of a protective oxide layer on its surface, which prevents further degradation from environmental factors.

- Marine Environments: Naval brass, which includes tin, is particularly resistant to saltwater corrosion, making it ideal for marine applications such as boat fittings, propellers, and underwater components.

- Plumbing Systems: Red brass is used in plumbing fittings due to its resistance to corrosion from water and household chemicals, ensuring long-lasting and reliable plumbing systems.

- Industrial Applications: Brass is utilized in heat exchangers and condensers that are exposed to corrosive fluids, extending the lifespan and efficiency of the equipment.

5.2 How Does Brass Have High Workability?

Brass is known for its high workability, meaning it can be easily shaped, formed, and machined into various components without fracturing.

- Machinability: Leaded brass, with a small addition of lead, exhibits excellent machinability, making it easier to cut and shape intricate parts with tight tolerances.

- Formability: Brass can be easily drawn into wires, rolled into sheets, and extruded into various shapes, allowing for the production of complex designs and components.

- Casting: Brass can be cast into complex shapes with fine details, making it suitable for decorative and functional parts.

5.3 How Does Brass Provide Good Electrical and Thermal Conductivity?

Brass offers good electrical and thermal conductivity, making it suitable for a range of applications requiring efficient energy transfer.

- Electrical Components: Brass is used in electrical connectors, terminals, and switches due to its ability to conduct electricity reliably.

- Heat Exchangers: Brass is used in heat exchangers and radiators for its ability to efficiently transfer heat between fluids.

- Electronic Devices: Brass is found in various electronic components where both conductivity and corrosion resistance are required.

5.4 What Is The Aesthetic Appeal Of Brass?

Brass has a warm, golden appearance that enhances the visual appeal of products, making it a popular choice for decorative applications.

- Decorative Hardware: Brass is used for door handles, knobs, cabinet pulls, and other decorative hardware to add a touch of elegance to interiors.

- Lighting Fixtures: Brass lighting fixtures, such as chandeliers and lamps, enhance the ambiance of spaces.

- Musical Instruments: Brass instruments, such as trumpets and trombones, are valued not only for their sound quality but also for their attractive appearance.

- Jewelry: Brass is used in jewelry making for its attractive color and workability, providing a cost-effective alternative to gold.

5.5 How Is Brass Durable and Long-Lasting?

Brass is a durable and long-lasting material that can withstand wear and tear, making it a reliable choice for various applications.

- Plumbing Systems: Brass pipes and fittings in plumbing systems can last for decades, providing reliable water and gas supply.

- Marine Applications: Brass components in marine environments resist corrosion and mechanical stress, ensuring long-term performance.

- Industrial Machinery: Brass gears and bearings in industrial machinery offer long-lasting performance under demanding conditions.

5.6 How Can Brass Be Recycled?

Brass is a recyclable material, which contributes to sustainability and reduces environmental impact.

- Recycling Process: Brass can be melted down and reused without significant loss of properties, making it an environmentally friendly choice.

- Reduced Waste: Recycling brass reduces the need for new raw materials and minimizes waste.

The advantages of using brass, including its corrosion resistance, workability, conductivity, aesthetic appeal, and recyclability, make it a preferred material in many industries.

Interested in learning more about the benefits of brass? Visit WHAT.EDU.VN for free, expert advice and quick answers.

6. How Is Brass Different From Bronze?

Brass and bronze are both copper alloys, but they differ significantly in their composition, properties, and applications. Understanding these differences is crucial for selecting the appropriate material for a specific purpose.

6.1 What Is The Composition Difference Between Brass And Bronze?

The primary difference between brass and bronze lies in their main alloying elements.

- Brass: Brass is primarily an alloy of copper and zinc. The proportion of zinc can vary, typically ranging from 5% to 45%, depending on the desired properties.

- Bronze: Bronze is primarily an alloy of copper and tin. Other elements, such as aluminum, manganese, or nickel, may also be added to enhance specific properties.

6.2 How Do The Properties Differ Between Brass And Bronze?

The difference in composition leads to variations in the properties of brass and bronze.

- Strength: Bronze generally has higher strength and hardness compared to brass. The addition of tin in bronze contributes to its increased tensile strength and resistance to wear.

- Corrosion Resistance: Both brass and bronze offer good corrosion resistance, but bronze typically performs better in marine environments. The presence of tin in bronze forms a protective layer that is more resistant to saltwater corrosion than the zinc oxide layer on brass.

- Ductility and Malleability: Brass generally has higher ductility and malleability compared to bronze, making it easier to form and shape without fracturing.

- Color: Brass typically has a brighter, more golden appearance, while bronze has a reddish-brown hue.

6.3 What Are The Typical Applications Of Brass Vs. Bronze?

Due to their differing properties, brass and bronze are used in different applications.

- Brass Applications:

- Plumbing Fittings: Brass is commonly used in plumbing fittings due to its corrosion resistance and workability.

- Musical Instruments: Brass is used in trumpets, trombones, and other instruments for its acoustic properties and aesthetic appeal.

- Electrical Connectors: Brass is used in electrical connectors and terminals for its good electrical conductivity.

- Ammunition: Brass is used in cartridge cases due to its malleability and ability to withstand high pressures.

- Bronze Applications:

- Marine Propellers: Bronze is used in marine propellers due to its high strength and corrosion resistance in saltwater.

- Bearings and Bushings: Bronze is used in bearings and bushings for its wear resistance and ability to withstand heavy loads.

- Springs: Bronze is used in springs for its fatigue resistance and ability to maintain its shape under stress.

- Statues and Sculptures: Bronze is used in statues and sculptures for its durability and aesthetic qualities.

6.4 What Are The Cost Differences Between Brass And Bronze?

The cost of brass and bronze can vary depending on the market prices of copper, zinc, and tin. Generally, brass tends to be less expensive than bronze due to the lower cost of zinc compared to tin. However, prices can fluctuate based on supply and demand.

6.5 What Are The Machinability Differences Between Brass And Bronze?

Brass generally has better machinability than bronze, especially when lead is added to the brass alloy. Leaded brass is easier to cut and shape, making it suitable for intricate parts requiring precise machining. Bronze can be more challenging to machine due to its higher strength and hardness.

6.6 How Do The Welding Properties Differ Between Brass And Bronze?

Both brass and bronze can be welded, but the process can be more complex compared to welding steel or aluminum. Special welding techniques and filler metals are often required to achieve strong and corrosion-resistant joints. Bronze welding can be more challenging due to its higher thermal conductivity and tendency to form oxides during welding.

Understanding the differences between brass and bronze in terms of composition, properties, applications, cost, machinability, and welding is essential for making informed decisions in engineering and manufacturing.

Do you have more questions about the differences between brass and bronze? Visit WHAT.EDU.VN for free, expert guidance and fast answers.

7. How Is Brass Recycled?

Recycling brass is an efficient and environmentally friendly process that helps conserve resources and reduce energy consumption. Brass can be recycled multiple times without significant loss of its properties, making it a sustainable material.

7.1 What Is The Process Of Recycling Brass?

The process of recycling brass involves several steps:

- Collection: Brass scrap is collected from various sources, including industrial facilities, construction sites, and recycling centers.

- Sorting: The collected scrap is sorted to remove any contaminants, such as other metals, plastics, and non-metallic materials.

- Melting: The sorted brass scrap is melted in a furnace at high temperatures. The melting process separates the different metals in the alloy, allowing them to be refined.

- Refining: The molten brass is refined to remove impurities and adjust the composition to meet specific requirements. This may involve adding or removing certain elements to achieve the desired properties.

- Casting: The refined molten brass is cast into ingots, billets, or other forms for further processing.

- Fabrication: The cast brass is then fabricated into new products, such as plumbing fittings, electrical components, and decorative hardware.

7.2 What Are The Environmental Benefits Of Recycling Brass?

Recycling brass offers several environmental benefits:

- Resource Conservation: Recycling brass reduces the need for mining new copper and zinc ores, conserving natural resources and reducing environmental impact.

- Energy Savings: Recycling brass requires significantly less energy compared to producing new brass from raw materials.

- Reduced Emissions: Recycling brass reduces greenhouse gas emissions and air pollution associated with mining, smelting, and refining virgin metals.

- Waste Reduction: Recycling brass diverts waste from landfills, reducing the volume of waste and minimizing environmental contamination.

7.3 What Are The Economic Benefits Of Recycling Brass?

Recycling brass also provides economic benefits:

- Cost Savings: Recycling brass can be more cost-effective than producing new brass from raw materials, reducing manufacturing costs.

- Job Creation: The recycling industry creates jobs in collection, sorting, processing, and manufacturing.

- Revenue Generation: Recycling brass generates revenue from the sale of recycled materials, contributing to economic growth.

7.4 How Can Consumers Contribute To Brass Recycling?

Consumers can play a vital role in promoting brass recycling by:

- Sorting Scrap: Separating brass items from other waste and placing them in designated recycling bins.

- Participating in Recycling Programs: Supporting local recycling programs and initiatives.

- Purchasing Recycled Products: Choosing products made from recycled brass to support the demand for recycled materials.

- Educating Others: Raising awareness about the benefits of recycling and encouraging others to participate.

Recycling brass is a sustainable practice that benefits the environment and the economy. By participating in brass recycling efforts, consumers and businesses can contribute to a more sustainable future.

Do you need more information on brass recycling? Get free, expert insights and quick answers at WHAT.EDU.VN today.

8. What Are The Disadvantages Of Using Brass?

While brass offers numerous advantages, it also has some disadvantages that should be considered when selecting materials for specific applications. These include lower strength compared to steel, potential for dezincification, tarnishing, and higher cost compared to some other materials.

8.1 How Does Brass Compare To Steel In Terms Of Strength?

Brass generally has lower strength compared to steel. Steel alloys, particularly those with high carbon content, offer significantly higher tensile strength, yield strength, and hardness. This makes steel more suitable for structural applications that require high load-bearing capacity and resistance to deformation.

- Tensile Strength: Steel typically has a tensile strength ranging from 400 to 2000 MPa, while brass ranges from 200 to 600 MPa.

- Yield Strength: Steel has a yield strength ranging from 200 to 1500 MPa, while brass ranges from 75 to 500 MPa.

- Hardness: Steel has a hardness ranging from 150 to 650 HB, while brass ranges from 50 to 200 HB.

8.2 What Is Dezincification And How Does It Affect Brass?

Dezincification is a form of corrosion that occurs in brass alloys with high zinc content (typically above 15%) when exposed to certain environments, particularly acidic or chloride-rich conditions.

- Process: Dezincification involves the selective removal of zinc from the brass alloy, leaving behind a porous, copper-rich structure. This weakens the material and reduces its mechanical properties.

- Impact: Dezincification can lead to leaks, cracks, and failures in brass components, especially in plumbing systems and marine applications.

- Prevention: Dezincification can be minimized by using dezincification-resistant brass alloys, controlling the environmental conditions, and applying protective coatings.

8.3 How Does Brass Tarnish Over Time?

Brass is prone to tarnishing, which is the formation of a dark, dull layer on the surface due to oxidation and reaction with atmospheric pollutants.

- Process: Tarnishing occurs when brass reacts with oxygen, sulfur, and other compounds in the air, forming a layer of oxides, sulfides, and other corrosion products.

- Impact: Tarnishing can affect the aesthetic appearance of brass items, making them look old and worn.

- Prevention: Tarnishing can be prevented or minimized by applying protective coatings, such as lacquers or waxes, and by regularly cleaning and polishing brass items.

8.4 What Is The Cost Of Brass Compared To Other Materials?

Brass can be more expensive than some other materials, such as aluminum and certain types of steel. The cost of brass depends on the market prices of copper and zinc, as well as the manufacturing processes involved.

- Material Costs: Copper and zinc are relatively expensive metals, which contributes to the higher cost of brass compared to materials like aluminum.

- Manufacturing Costs: The manufacturing processes involved in producing brass components, such as casting, machining, and finishing, can also add to the overall cost.

8.5 How Does Brass Perform At High Temperatures?

Brass has a lower melting point compared to steel and other high-temperature alloys, which limits its use in high-temperature applications.

- Melting Point: Brass typically has a melting point ranging from 900 to 940 degrees Celsius, while steel has a melting point ranging from 1370 to 1510 degrees Celsius.

- Strength Reduction: Brass loses strength and hardness at elevated temperatures, which can lead to deformation and failure.

While brass offers numerous advantages, it is essential to consider its disadvantages, such as lower strength, potential for dezincification, tarnishing, and higher cost, when selecting materials for specific applications.

Want to explore more about the downsides of using brass? Get free expert insights and answers at WHAT.EDU.VN today.

9. How To Identify Brass?

Identifying brass can be essential in various situations, whether you are sorting scrap metal, evaluating materials for a project, or authenticating antique items. Here are several methods to help you identify brass accurately.

9.1 What Are The Visual Characteristics Of Brass?

Visual inspection is often the first step in identifying brass. Look for these characteristics:

- Color: Brass typically has a golden-yellow color, which can vary depending on the zinc content. Some brass alloys may have a reddish-gold or silvery-yellow hue.

- Luster: Brass has a metallic luster, meaning it reflects light and appears shiny when polished.

- Tarnish: Over time, brass can develop a greenish or brownish tarnish on its surface due to oxidation.

- Markings: Check for any markings, stamps, or engravings that may indicate the type of brass or its manufacturer.

9.2 How Can You Use A Magnet To Identify Brass?

Brass is a non-ferrous metal, meaning it does not contain iron and is not magnetic.

- Test: Use a magnet to test the material. If the magnet does not stick to the metal, it is likely brass, bronze, copper, or aluminum. If the magnet sticks, the material is likely steel or iron.

9.3 How Can You Perform A Scratch Test To Identify Brass?

A scratch test can help differentiate brass from other metals based on its hardness and color.

- Procedure: Use a file or sharp object to scratch the surface of the material.

- Observation: Brass is relatively soft compared to steel but harder than aluminum. The scratch will reveal a golden-yellow color beneath the surface.

9.4 How Can You Use A Chemical Test To Identify Brass?

Chemical tests can provide more definitive identification of brass.

- Acid Test: Apply a drop of dilute nitric acid to the surface of the material. Brass will react with the acid, producing a green or blue solution due to the presence of copper and zinc.

- Ammonia Test: Expose the material to ammonia vapor. Brass will turn a deep blue color due to the formation of copper-ammonia complexes.

9.5 How Can You Use A Spark Test To Identify Brass?

A spark test involves grinding the material against a grinding wheel and observing the resulting sparks.

- Procedure: Hold the material against a grinding wheel and observe the sparks.

- Observation: Brass produces short, dull orange sparks with few or no branches. This is different from steel, which produces bright, branching sparks.

9.6 How Can You Compare The Density To Identify Brass?

Measuring the density of the material can help identify brass accurately.

- Procedure: Measure the mass and volume of the material.

- Calculation: Calculate the density using the formula: Density = Mass / Volume.

- Comparison: Compare the calculated density to the known density of brass (typically around 8.4 to 8.7 g/cm³).

By using these methods, you can accurately identify brass and differentiate it from other metals.

Do you need more tips on how to identify brass? Get free, expert guidance and fast answers at what.edu.vn today.

10. What Are Some Common Problems With Brass And How To Solve Them?

Brass, while versatile and durable, is susceptible to certain issues. Understanding these problems and their solutions can extend the lifespan and maintain the quality of brass components.

10.1 How To Solve Dezincification In Brass?

Dezincification is the selective leaching of zinc from brass alloys, leading to a weakened, porous structure.

- Problem: Dezincification occurs in brass alloys with high zinc content when exposed to acidic or chloride-rich environments.

- Solution:

- Use Dezincification-Resistant Brass: Select brass alloys specifically designed to resist dezincification, such as those with added arsenic or tin.

- Control Environmental Conditions: Minimize exposure to acidic or chloride-rich environments by using water treatment or protective coatings.