Nylon, a versatile synthetic fabric, has revolutionized various industries. At WHAT.EDU.VN, we unravel the mysteries of nylon, exploring its composition, manufacturing, applications, and environmental impact while offering solutions to your queries. Dive in to discover the nylon material and its role in fashion, industry, and everyday life. Discover the differences between nylon variants like nylon 6 and nylon 6,6 and explore sustainable alternatives with us for free.

1. What Is Nylon and Its History?

Nylon is a synthetic polymer, specifically a polyamide, known for its strength, elasticity, and durability. It’s a thermoplastic silky material that can be drawn into fibers, films, or shapes, making it incredibly versatile.

1.1. The Birth of Nylon: A DuPont Innovation

Nylon’s story begins in the 1930s at DuPont’s research facility, led by Wallace Carothers. The goal was to create a synthetic fiber that could rival silk, which was expensive and supply-limited at the time. In 1935, Carothers and his team successfully synthesized nylon 6,6, the first commercially successful synthetic polymer fiber.

1.2. “Nylons”: The Hosiery Revolution

Nylon’s debut in 1939 at the New York World’s Fair was a sensation. Its first major application was in women’s stockings, marketed as “nylons.” They were strong, sheer, and more affordable than silk stockings, leading to a massive consumer demand.

1.3. Nylon in World War II: A Strategic Material

The onset of World War II shifted nylon production towards military applications. It was used extensively for parachutes, ropes, tires, tents, and other essential war materials, showcasing its strength and resilience.

1.4. Post-War Boom: Nylon’s Expanding Applications

After the war, nylon production expanded into various consumer goods, including clothing, carpets, upholstery, and industrial components. Its versatility and cost-effectiveness made it a popular choice across industries.

1.5. The Evolution of Nylon: New Variants and Improvements

Over the years, different types of nylon polymers have been developed, each with specific properties tailored to various applications. These include nylon 6, nylon 11, nylon 12, and others, each offering unique advantages.

2. What Are the Key Properties of Nylon Fabric?

Nylon’s popularity stems from its unique combination of properties that make it suitable for a wide range of applications.

2.1. High Strength and Durability

Nylon fibers are exceptionally strong and resistant to abrasion, making them ideal for applications where durability is crucial, such as ropes, tires, and protective clothing.

2.2. Elasticity and Flexibility

Nylon has excellent elasticity, allowing it to stretch and recover its original shape. This makes it comfortable to wear in clothing and suitable for applications requiring flexibility.

2.3. Resistance to Chemicals and Abrasion

Nylon is resistant to many chemicals, oils, and solvents, making it useful in industrial settings. It also resists abrasion, ensuring longevity in demanding applications.

2.4. Lightweight and Quick-Drying

Nylon is a lightweight material, making it comfortable to wear. It also dries quickly, making it suitable for sportswear and outdoor gear.

2.5. Lustrous Appearance

Nylon fibers have a natural sheen, giving them a lustrous appearance that enhances the look of fabrics and products.

2.6. Easy to Dye and Colorfast

Nylon readily accepts dyes, allowing for a wide range of colors and patterns. It also exhibits good colorfastness, meaning the colors resist fading over time.

3. How Is Nylon Fabric Made: The Manufacturing Process Explained?

The manufacturing of nylon involves a complex chemical process that transforms raw materials into versatile fibers and polymers.

3.1. Polymerization: Creating the Nylon Polymer

The first step is polymerization, where small molecules (monomers) are chemically bonded together to form long chains (polymers). For nylon 6,6, the monomers are adipic acid and hexamethylenediamine. For nylon 6, the monomer is caprolactam.

3.2. Melt Spinning: Forming the Fibers

The nylon polymer is then melted and forced through small holes in a spinneret, a device similar to a showerhead. As the molten polymer emerges, it cools and solidifies into continuous filaments.

3.3. Drawing: Strengthening the Fibers

The filaments are then stretched, or “drawn,” to align the polymer chains, increasing their strength, elasticity, and uniformity.

3.4. Texturing and Finishing: Enhancing Properties

The fibers can be textured to create different surface effects, such as crimping or looping. They are then treated with finishes to improve properties like water resistance, UV protection, or antimicrobial performance.

3.5. Fabric Production: Weaving or Knitting

The nylon fibers are then spun into yarns, which are woven or knitted into fabrics. These fabrics can be used for a wide variety of applications, from clothing to industrial textiles.

4. What Are the Different Types of Nylon?

Nylon comes in various types, each with unique properties and applications. Here are some of the most common:

4.1. Nylon 6,6: The Original Nylon

Nylon 6,6 is the first type of nylon to have been synthesized. It is known for its high strength, stiffness, and heat resistance. It is commonly used in textiles, automotive parts, and industrial components.

4.2. Nylon 6: A Versatile Alternative

Nylon 6 is similar to nylon 6,6 but has slightly lower strength and stiffness. It is easier to dye and process, making it a popular choice for clothing, carpets, and packaging films.

4.3. Nylon 11: A Bio-Based Option

Nylon 11 is derived from castor oil, a renewable resource. It has excellent flexibility, impact resistance, and chemical resistance. It is used in automotive parts, sports equipment, and electrical cables.

4.4. Nylon 12: Low Water Absorption

Nylon 12 has the lowest water absorption of all common nylons. It maintains its properties even in humid environments, making it suitable for plumbing components, cable coatings, and automotive fuel lines.

4.5. Specialty Nylons: Tailored Properties

Other specialty nylons, such as nylon 46, nylon 610, and nylon 612, offer tailored properties for specific applications. These may include enhanced heat resistance, chemical resistance, or UV resistance.

5. What Are the Common Uses of Nylon Fabric?

Nylon’s versatility has led to its widespread use in various industries and consumer products.

5.1. Apparel: From Stockings to Sportswear

Nylon is used extensively in clothing, including stockings, lingerie, swimwear, sportswear, and outerwear. Its strength, elasticity, and quick-drying properties make it ideal for activewear and functional garments.

5.2. Home Furnishings: Carpets and Upholstery

Nylon fibers are used in carpets, rugs, and upholstery fabrics due to their durability, stain resistance, and ease of cleaning. They can withstand heavy foot traffic and maintain their appearance over time.

5.3. Industrial Applications: Ropes, Tires, and More

Nylon is used in industrial applications such as ropes, cords, tires, seatbelts, and conveyor belts due to its high strength, abrasion resistance, and chemical resistance.

5.4. Automotive Parts: Engine Components and Interiors

Nylon is used in automotive parts such as engine covers, radiator end tanks, and interior trim components due to its heat resistance, chemical resistance, and durability.

5.5. Packaging Films: Food and Industrial Products

Nylon films are used in packaging for food, pharmaceuticals, and industrial products due to their barrier properties, strength, and puncture resistance.

5.6. Fishing Nets and Lines: Strength and Durability

Nylon’s strength and resistance to degradation in water make it ideal for fishing nets, lines, and other marine applications.

6. What Are the Benefits of Using Nylon?

Nylon offers several advantages that make it a popular choice across industries:

6.1. High Strength-to-Weight Ratio

Nylon is incredibly strong for its weight, making it ideal for applications where weight is a concern.

6.2. Excellent Abrasion Resistance

Nylon resists wear and tear, making it durable and long-lasting in demanding applications.

6.3. Resistance to Chemicals and Solvents

Nylon withstands exposure to many chemicals and solvents, making it suitable for industrial environments.

6.4. Elasticity and Flexibility

Nylon stretches and recovers its shape, providing comfort and flexibility in clothing and other applications.

6.5. Versatility in Applications

Nylon can be tailored to meet the specific needs of various applications, making it a versatile material.

6.6. Cost-Effectiveness

Nylon is relatively inexpensive to produce, making it a cost-effective alternative to natural fibers and other synthetic materials.

7. What Are the Drawbacks of Using Nylon?

Despite its many benefits, nylon also has some drawbacks:

7.1. Environmental Concerns

Nylon is derived from petroleum, a non-renewable resource. Its production also releases greenhouse gases and other pollutants.

7.2. Non-Biodegradable

Nylon does not readily biodegrade, contributing to plastic waste and environmental pollution.

7.3. Moisture Absorption

Nylon tends to absorb moisture, which can make it feel clammy in clothing and affect its performance in some applications.

7.4. Static Electricity

Nylon can generate static electricity, which can be uncomfortable in clothing and attract dust and dirt.

7.5. Susceptibility to UV Degradation

Nylon can degrade when exposed to ultraviolet (UV) radiation, causing it to weaken and discolor over time.

8. How to Care for Nylon Fabrics?

Proper care can extend the life of nylon fabrics and maintain their appearance and performance.

8.1. Washing Instructions

- Machine wash in cold or warm water with a mild detergent.

- Avoid using bleach, as it can damage the fibers.

- Wash with similar colors to prevent color bleeding.

8.2. Drying Instructions

- Tumble dry on low heat or hang to dry.

- Avoid high heat, as it can shrink or damage the fabric.

- Do not iron nylon fabrics, as they can melt or scorch easily.

8.3. Storage Instructions

- Store nylon fabrics in a cool, dry place away from direct sunlight.

- Avoid storing nylon fabrics in airtight containers, as they need to breathe.

8.4. Stain Removal

- Treat stains as soon as possible to prevent them from setting.

- Use a mild stain remover or detergent and gently blot the stain.

- Avoid rubbing the stain, as it can spread or damage the fabric.

9. What Is the Environmental Impact of Nylon and Sustainability Efforts?

Nylon’s environmental impact is a growing concern, and efforts are underway to make its production and use more sustainable.

9.1. The Environmental Footprint of Nylon Production

Nylon production contributes to greenhouse gas emissions, water pollution, and solid waste. The extraction and processing of petroleum, the primary raw material, have significant environmental consequences.

9.2. Recycling Nylon: Closing the Loop

Recycling nylon is an important step towards reducing its environmental impact. Nylon can be recycled from pre-consumer waste (such as manufacturing scraps) and post-consumer waste (such as used carpets and fishing nets).

9.3. Bio-Based Nylons: A Renewable Alternative

Bio-based nylons, such as nylon 11, are derived from renewable resources like castor oil. These alternatives reduce reliance on petroleum and offer a lower carbon footprint.

9.4. Sustainable Manufacturing Practices

Sustainable manufacturing practices, such as reducing water and energy consumption, minimizing waste, and using cleaner production technologies, can help mitigate the environmental impact of nylon production.

9.5. Consumer Choices: Supporting Sustainable Options

Consumers can play a role in promoting sustainability by choosing products made from recycled nylon or bio-based nylons and supporting companies committed to sustainable practices.

10. Nylon vs. Other Fabrics: A Comparison

Nylon is often compared to other fabrics, both natural and synthetic, in terms of properties, performance, and environmental impact.

10.1. Nylon vs. Polyester

- Nylon is stronger and more elastic than polyester.

- Polyester is more resistant to UV degradation and water absorption.

- Both are synthetic fabrics derived from petroleum.

- Polyester is generally less expensive than nylon.

10.2. Nylon vs. Cotton

- Nylon is stronger, more durable, and more abrasion-resistant than cotton.

- Cotton is more breathable and absorbent than nylon.

- Cotton is a natural fiber, while nylon is synthetic.

- Cotton is generally more comfortable for everyday wear.

10.3. Nylon vs. Silk

- Nylon is stronger, more durable, and less expensive than silk.

- Silk has a luxurious feel and drape that nylon cannot replicate.

- Silk is a natural fiber, while nylon is synthetic.

- Silk requires more delicate care than nylon.

10.4. Nylon vs. Wool

- Nylon is stronger, more durable, and more abrasion-resistant than wool.

- Wool is warmer, more absorbent, and more breathable than nylon.

- Wool is a natural fiber, while nylon is synthetic.

- Wool requires more specialized care than nylon.

11. What Are Some Interesting Facts About Nylon?

Nylon has a fascinating history and unique properties that make it a noteworthy material.

11.1. “Nylon” May Not Stand for Anything

The origin of the name “nylon” is debated. Some believe it combines “New York” and “London,” while others say it was chosen arbitrarily. DuPont has maintained that the name doesn’t stand for anything specific.

11.2. Nylon Was Initially Marketed as “Stronger Than Steel”

While nylon is strong, this claim was an exaggeration used for marketing purposes.

11.3. Nylon Played a Crucial Role in World War II

Nylon’s use in parachutes, ropes, and other military equipment was essential to the war effort.

11.4. Nylon Revolutionized the Fashion Industry

Nylon stockings and other garments transformed women’s fashion in the mid-20th century.

11.5. Nylon Is Used in Musical Instruments

Nylon strings are commonly used in classical guitars and other stringed instruments.

12. What Are the Future Trends in Nylon?

Nylon continues to evolve, with ongoing research and development focused on improving its properties, sustainability, and applications.

12.1. Increased Use of Recycled Nylon

Recycled nylon is gaining popularity as a sustainable alternative to virgin nylon.

12.2. Development of New Bio-Based Nylons

Researchers are exploring new bio-based nylon options derived from renewable resources.

12.3. Enhanced Performance Properties

Efforts are underway to improve nylon’s heat resistance, chemical resistance, and UV resistance.

12.4. Smart Nylons with Embedded Technologies

Nylon fabrics with embedded sensors and other technologies are being developed for applications in healthcare, sports, and defense.

12.5. 3D-Printed Nylon Components

3D printing with nylon is enabling the creation of complex, customized parts for various industries.

13. FAQs About Nylon

Here are some frequently asked questions about nylon:

| Question | Answer |

|---|---|

| What Is Nylon made from? | Nylon is typically made from petroleum-derived chemicals, but bio-based options are also available. |

| Is nylon waterproof? | Nylon is water-resistant but not completely waterproof. It can repel water to some extent, but prolonged exposure will eventually lead to saturation. |

| Is nylon breathable? | Nylon is not very breathable compared to natural fibers like cotton. However, some nylon fabrics are designed with enhanced breathability. |

| Is nylon stretchy? | Nylon has good elasticity, allowing it to stretch and recover its shape. |

| How strong is nylon? | Nylon is a strong and durable material, making it suitable for demanding applications. |

| Is nylon recyclable? | Yes, nylon can be recycled, and recycled nylon is becoming increasingly popular. |

| Is nylon expensive? | Nylon is relatively inexpensive compared to other synthetic and natural fibers. |

| Is nylon safe to wear? | Nylon is generally safe to wear, but some people may be sensitive to the chemicals used in its production. |

| How does nylon compare to other fabrics? | Nylon has different properties than other fabrics, making it suitable for different applications. See the comparison section for more details. |

| Where can I buy nylon fabric? | Nylon fabric is available at fabric stores, online retailers, and suppliers of industrial textiles. |

14. Get Your Questions Answered for Free at WHAT.EDU.VN

Do you have more questions about nylon or other materials? At WHAT.EDU.VN, we provide a free platform to ask any question and receive answers from knowledgeable experts. Our community is dedicated to providing accurate, helpful information to satisfy your curiosity.

14.1. Ask Anything, Get Answers

Whether you are curious about the science behind materials, need help with a project, or simply want to learn something new, WHAT.EDU.VN is here to help. Our platform is designed to make learning easy and accessible for everyone.

14.2. Expert Insights and Community Support

Our team of experts and community members are ready to provide detailed answers and support. You can trust that the information you receive is accurate and reliable.

14.3. Convenient and Free Access

Accessing our services is easy and completely free. Simply visit WHAT.EDU.VN, ask your question, and let our community do the rest.

14.4. Contact Us

For any inquiries or further assistance, feel free to reach out to us:

- Address: 888 Question City Plaza, Seattle, WA 98101, United States

- WhatsApp: +1 (206) 555-7890

- Website: WHAT.EDU.VN

15. Call to Action: Ask Your Questions Today

Ready to dive deeper and get personalized answers? Visit WHAT.EDU.VN today and ask any question you have. Our community is eager to help you explore the world of knowledge, completely free of charge. Don’t hesitate—your questions are welcome here.

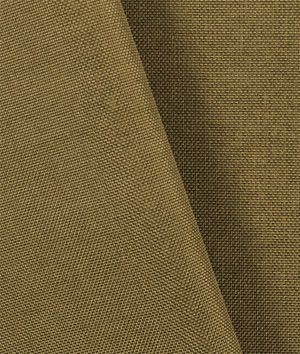

coyote brown 1000 denier cordura nylon fabric

coyote brown 1000 denier cordura nylon fabric

Alt: Durable coyote brown Cordura nylon fabric, ideal for heavy-duty applications

Nylon stands as a testament to human innovation, transforming industries and improving lives with its unique blend of properties. While its environmental impact remains a concern, ongoing efforts to develop sustainable alternatives and recycling programs offer hope for a more eco-friendly future. At what.edu.vn, we are committed to providing you with the knowledge and resources to make informed decisions about this remarkable material.