Ever wondered how industries keep their processes running seamlessly? A Programmable Logic Controller, or PLC, is the answer. At WHAT.EDU.VN, we provide a comprehensive understanding of PLC systems, ensuring you grasp their functionality and benefits, offering clarity and solutions to your queries. Explore the world of industrial automation with our educational resources and gain insights into controller technology, automation processes and industrial control systems.

1. What Is PLC and How Does It Work?

A Programmable Logic Controller (PLC) is a specialized computer system used to control automated processes in industries such as petroleum, steel, and automotive. According to a 2023 report by Grand View Research, the global PLC market is expected to reach $17.14 billion by 2030, highlighting its importance in modern industrial operations.

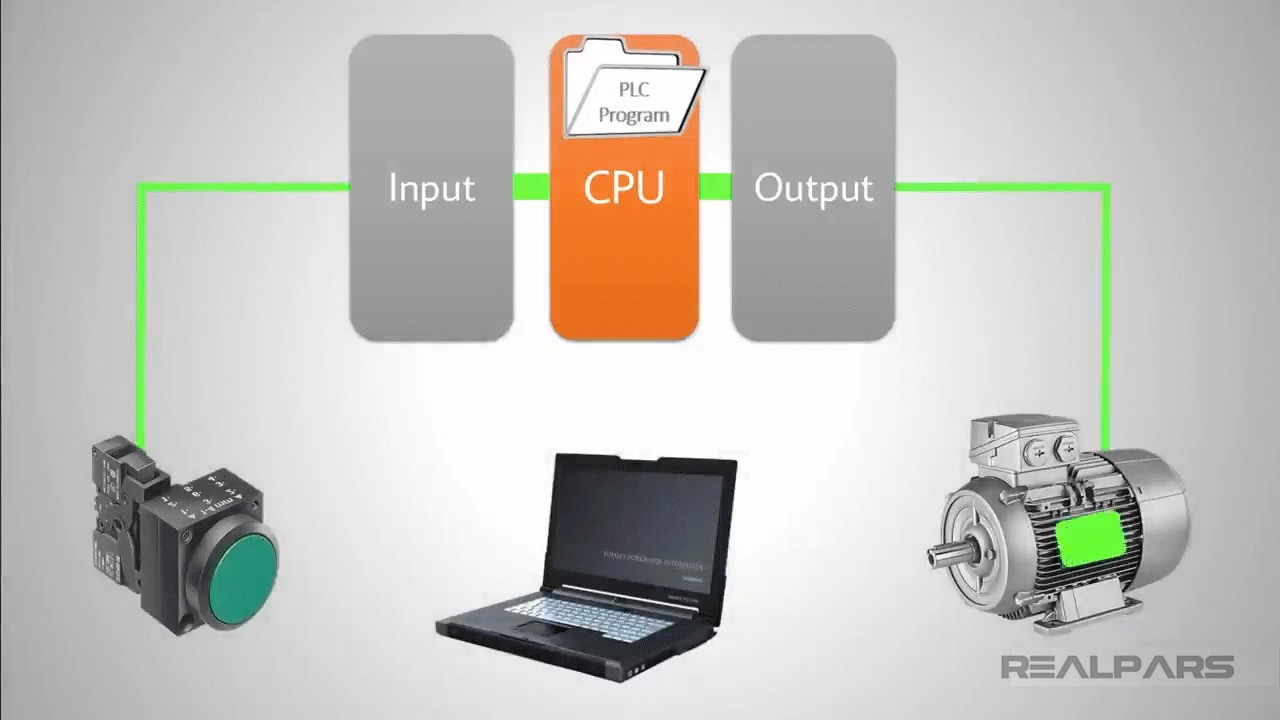

Every PLC consists of three main components:

- Input Modules: These receive signals from sensors or switches.

- CPU (Central Processing Unit): This processes the input signals according to a programmed logic.

- Output Modules: These send signals to control devices like motors or valves.

To illustrate how a PLC works, consider a simple example: controlling an electric motor with a push button.

-

Programming: A program is written on a computer and downloaded to the CPU of the PLC. This program defines the logic for controlling the motor.

-

Input Connection: The push button is connected to an input module of the PLC.

-

Output Connection: The electric motor is connected to an output module of the PLC.

-

Operation:

- When the button is pressed, an electrical signal is sent to the PLC’s input module.

- The input module converts this signal into a format that the CPU can process.

- The CPU processes the data based on the programmed logic.

- The CPU sends a signal to the output module.

- The output module converts this signal back into an electrical signal and sends it to the motor, turning it on.

- When the button is pressed again, the process repeats, and the motor turns off.

Programmable Logic Controller Operation

Programmable Logic Controller Operation

This functionality is similar to the power button on a TV remote, where a single press can toggle the device on or off.

2. What Are the Key Components of a PLC System?

A PLC system comprises several key components that work together to automate industrial processes. These components include the power supply, input/output (I/O) modules, the central processing unit (CPU), and the programming device. Understanding each component is crucial for effectively utilizing PLC systems.

-

Power Supply: This provides the necessary power to the PLC system. It converts AC power from the main supply into DC power required by the PLC’s internal circuits.

-

Input/Output (I/O) Modules:

- Input Modules: These receive signals from field devices such as sensors, switches, and encoders. They convert these signals into a format that the CPU can understand.

- Output Modules: These send control signals to field devices such as motors, valves, and actuators. They convert signals from the CPU into a format that these devices can use.

-

CPU (Central Processing Unit): The brain of the PLC, the CPU executes the control program. It processes input signals, makes decisions based on the program logic, and sends output signals to control the connected devices.

-

Programming Device: This is used to write, edit, and monitor the PLC program. It can be a personal computer with PLC programming software or a dedicated programming terminal.

3. Why Is PLC Important in Industrial Automation?

PLCs are vital in industrial automation because they offer several advantages over traditional relay-based control systems. According to a 2024 report by Mordor Intelligence, the increasing adoption of automation in industries such as automotive, food and beverage, and pharmaceuticals is driving the demand for PLCs.

- Flexibility: PLCs can be easily reprogrammed to change the control logic, making them suitable for various applications.

- Reliability: PLCs are designed to withstand harsh industrial environments and provide consistent performance.

- Cost-Effectiveness: While the initial investment may be higher than relay-based systems, PLCs reduce downtime and maintenance costs in the long run.

- Advanced Functionality: PLCs can perform complex control functions such as PID control, data logging, and communication with other devices.

- Easy Troubleshooting: PLCs have built-in diagnostic tools that help identify and resolve issues quickly.

4. What Are the Different Types of PLCs Available?

PLCs come in various types, each suited for different applications and scales of automation. Understanding these types helps in selecting the appropriate PLC for a specific industrial need. Here’s a breakdown of the main types:

- Compact PLCs: These are small, all-in-one units with a fixed number of I/O points. They are suitable for small to medium-sized applications.

- Modular PLCs: These consist of separate modules for the CPU, power supply, and I/O. They offer greater flexibility and scalability, making them ideal for larger, more complex applications.

- Rack-Mounted PLCs: These are designed to be mounted in a rack, allowing for easy expansion and maintenance. They are commonly used in large industrial plants.

- Distributed PLCs: These are used in systems where the I/O is distributed across a large area. They communicate with a central controller via a network, allowing for decentralized control.

- Safety PLCs: These are designed for safety-critical applications where failure could result in injury or damage. They include redundant hardware and software to ensure high reliability.

5. How Do You Program a PLC?

Programming a PLC involves creating a control program that defines how the PLC will respond to inputs and control outputs. There are several programming languages commonly used for PLCs, each with its own syntax and features.

- Ladder Logic: This is the most common programming language for PLCs. It uses symbols similar to those used in electrical ladder diagrams, making it easy for electricians and technicians to understand.

- Function Block Diagram (FBD): This uses graphical blocks to represent functions and connect them together to create the control logic. It is well-suited for complex control algorithms.

- Structured Text (ST): This is a high-level programming language similar to Pascal or C. It is useful for implementing complex logic and calculations.

- Instruction List (IL): This is a low-level assembly language that provides direct control over the PLC’s hardware.

- Sequential Function Chart (SFC): This is a graphical language used to represent sequential control processes. It is useful for applications with multiple steps or states.

To program a PLC, you typically use PLC programming software on a computer. This software allows you to write, edit, and download the program to the PLC.

6. What Are the Advantages of Using PLC Over Relay Logic?

PLCs offer several advantages over traditional relay logic systems, making them the preferred choice for modern industrial automation. According to a 2022 study by ARC Advisory Group, PLCs reduce downtime by up to 50% compared to relay logic systems.

- Flexibility and Scalability: PLCs are easily reprogrammed and expanded, allowing for changes and upgrades without rewiring.

- Reliability: PLCs are designed to withstand harsh industrial environments and offer consistent performance over long periods.

- Advanced Functionality: PLCs can perform complex control functions, such as PID control, data logging, and communication with other devices, which are difficult or impossible to implement with relay logic.

- Reduced Wiring: PLCs require less wiring than relay logic systems, reducing installation and maintenance costs.

- Diagnostics and Troubleshooting: PLCs have built-in diagnostic tools that make it easier to identify and resolve issues, reducing downtime.

7. What Are Some Common Applications of PLC in Industries?

PLCs are used in a wide range of industries to automate various processes. Their versatility and reliability make them suitable for numerous applications.

- Manufacturing: PLCs control assembly lines, robotic systems, and automated machinery in manufacturing plants.

- Automotive: PLCs manage production lines, paint shops, and engine testing facilities in the automotive industry.

- Oil and Gas: PLCs monitor and control pipelines, refineries, and offshore platforms in the oil and gas sector.

- Food and Beverage: PLCs automate packaging, bottling, and processing operations in the food and beverage industry.

- Water and Wastewater Treatment: PLCs control pumps, valves, and filtration systems in water and wastewater treatment plants.

- Power Generation: PLCs manage turbines, generators, and distribution systems in power plants.

- Pharmaceuticals: PLCs control batch processes, sterilization systems, and packaging lines in the pharmaceutical industry.

8. How Do You Troubleshoot a PLC System?

Troubleshooting a PLC system involves identifying and resolving issues that prevent the system from functioning correctly. A systematic approach is essential for effective troubleshooting.

- Check Power Supply: Ensure that the PLC and all connected devices are receiving power.

- Verify Input Signals: Check that input devices (sensors, switches) are sending the correct signals to the PLC.

- Examine Output Signals: Verify that the PLC is sending the correct signals to output devices (motors, valves).

- Review the PLC Program: Look for errors or inconsistencies in the PLC program.

- Use Diagnostic Tools: Utilize the PLC’s built-in diagnostic tools to identify faults and error messages.

- Inspect Wiring: Check for loose or damaged wiring connections.

- Test Components: Test individual components (I/O modules, CPU) to isolate the problem.

- Consult Documentation: Refer to the PLC’s documentation for troubleshooting tips and error code explanations.

9. What Is the Future of PLC Technology?

The future of PLC technology is focused on enhanced connectivity, integration with cloud computing, and improved cybersecurity. According to a 2023 report by MarketsandMarkets, the industrial control and factory automation market is expected to reach $209.7 billion by 2028, driven by advancements in PLC technology.

- Connectivity and IoT Integration: PLCs are increasingly being integrated with the Internet of Things (IoT) to enable remote monitoring and control.

- Cloud Computing: PLCs are leveraging cloud computing for data storage, analytics, and remote programming.

- Cybersecurity: PLCs are incorporating advanced security features to protect against cyber threats and ensure data integrity.

- Artificial Intelligence (AI): PLCs are integrating AI algorithms to optimize control processes and improve efficiency.

- Edge Computing: PLCs are using edge computing to process data locally, reducing latency and improving real-time performance.

10. Where Can I Learn More About PLCs?

To learn more about PLCs, various resources are available, including online courses, training programs, and educational websites.

- Online Courses: Platforms like Coursera, Udemy, and edX offer courses on PLC programming and industrial automation.

- Training Programs: PLC manufacturers such as Siemens, Allen-Bradley, and Mitsubishi offer training programs for their products.

- Educational Websites: Websites like WHAT.EDU.VN provide articles, tutorials, and resources on PLC technology.

- Technical Books: Books like “Programmable Logic Controllers” by Frank Petruzella and “PLC Programming Using RSLogix 500” by Gary Dunning offer in-depth knowledge of PLCs.

- Industry Conferences: Conferences like Automation Fair and Hannover Messe provide opportunities to learn about the latest PLC technologies and network with industry professionals.

11. What Are the Safety Considerations When Working With PLCs?

Working with PLCs involves several safety considerations to prevent accidents and ensure a safe working environment.

- Electrical Safety: Always disconnect power before working on PLC systems to avoid electrical shock.

- Lockout/Tagout: Use lockout/tagout procedures to prevent accidental energization of equipment during maintenance.

- Proper Grounding: Ensure that all PLC components are properly grounded to prevent electrical hazards.

- Personal Protective Equipment (PPE): Wear appropriate PPE, such as safety glasses and gloves, when working with PLCs.

- Follow Manufacturer’s Instructions: Adhere to the manufacturer’s instructions for installation, operation, and maintenance of PLC systems.

- Emergency Shutdown Procedures: Know the emergency shutdown procedures for the equipment controlled by the PLC.

- Regular Inspections: Conduct regular inspections of PLC systems to identify and address potential safety hazards.

12. How Can PLCs Improve Efficiency in Manufacturing?

PLCs significantly enhance efficiency in manufacturing processes by automating and optimizing various operations. A 2021 report by Deloitte indicates that manufacturers using PLCs have seen a 20% increase in overall equipment effectiveness (OEE).

- Automated Control: PLCs automate repetitive tasks, reducing human error and increasing production speed.

- Real-Time Monitoring: PLCs provide real-time data on equipment performance, allowing for timely adjustments and preventive maintenance.

- Optimized Processes: PLCs optimize control parameters to improve product quality and reduce waste.

- Integration with Other Systems: PLCs can be integrated with other manufacturing systems, such as ERP and MES, to streamline operations.

- Flexible Production: PLCs enable manufacturers to quickly adapt to changing market demands by easily modifying control programs.

13. What Role Do Sensors Play in a PLC System?

Sensors are crucial components in a PLC system as they provide the necessary input data for the PLC to make informed control decisions. According to a 2022 study by Allied Market Research, the global industrial sensors market is expected to reach $27.2 billion by 2030, highlighting their importance in PLC-based automation systems.

- Data Acquisition: Sensors measure physical parameters such as temperature, pressure, level, and flow, and convert them into electrical signals.

- Input to PLC: These electrical signals are sent to the PLC’s input modules, where they are processed by the CPU.

- Feedback Control: The PLC uses the sensor data to monitor and control the process, ensuring that it operates within the desired parameters.

- Types of Sensors: Common types of sensors used in PLC systems include temperature sensors, pressure sensors, level sensors, flow sensors, proximity sensors, and encoders.

- Accuracy and Reliability: The accuracy and reliability of sensors are critical for the performance of the PLC system.

14. How Are PLCs Used in the Water Treatment Industry?

PLCs play a critical role in the water treatment industry by automating and controlling various processes, ensuring the efficient and safe treatment of water. A 2023 report by Bluefield Research indicates that the adoption of PLC-based automation in water treatment plants has increased by 30% in the last five years.

- Monitoring Water Quality: PLCs monitor water quality parameters such as pH, turbidity, and chlorine levels.

- Controlling Pumps and Valves: PLCs control pumps and valves to regulate water flow and pressure.

- Automating Filtration Systems: PLCs automate filtration systems to remove impurities from the water.

- Managing Chemical Dosing: PLCs manage chemical dosing to ensure proper disinfection and treatment.

- Optimizing Energy Consumption: PLCs optimize energy consumption by controlling pumps and equipment based on demand.

15. What Is the Difference Between a PLC and a DCS?

While both PLCs and Distributed Control Systems (DCS) are used for industrial automation, they have distinct differences in terms of architecture, application, and scalability.

| Feature | PLC | DCS |

|---|---|---|

| Architecture | Centralized | Distributed |

| Application | Discrete Control | Process Control |

| Scalability | Limited | High |

| Response Time | Fast | Slower |

| Programming | Ladder Logic, Function Block Diagram | Function Block Diagram, Structured Text |

| Industry Use | Manufacturing, Automotive | Oil and Gas, Chemical |

- PLC (Programmable Logic Controller): A PLC is a centralized control system that is primarily used for discrete control applications, such as controlling machines and assembly lines.

- DCS (Distributed Control System): A DCS is a distributed control system that is used for process control applications, such as controlling continuous processes in chemical plants and refineries.

16. How Do PLCs Integrate with SCADA Systems?

PLCs often integrate with Supervisory Control and Data Acquisition (SCADA) systems to provide a comprehensive solution for industrial automation. According to a 2024 report by Global Market Insights, the SCADA market is expected to reach $40.1 billion by 2032, driven by the integration of PLCs with SCADA systems.

- Data Acquisition: PLCs collect data from sensors and field devices and transmit it to the SCADA system.

- Supervisory Control: The SCADA system provides a central interface for operators to monitor and control the PLC system.

- Data Logging and Analysis: The SCADA system logs historical data and provides tools for analyzing trends and performance.

- Remote Monitoring: SCADA systems enable remote monitoring and control of PLC systems, allowing operators to manage processes from anywhere.

- Alarm Management: SCADA systems provide alarm management capabilities, alerting operators to abnormal conditions and potential problems.

17. What Are the Key Considerations When Selecting a PLC for an Application?

Selecting the right PLC for a specific application requires careful consideration of several factors to ensure that the PLC meets the requirements of the application.

- Number of I/O Points: Determine the number of input and output points required for the application.

- Processing Speed: Choose a PLC with sufficient processing speed to handle the application’s control requirements.

- Memory Capacity: Ensure that the PLC has enough memory to store the control program and data.

- Communication Capabilities: Select a PLC with the necessary communication interfaces to connect to other devices and systems.

- Environmental Conditions: Choose a PLC that is designed to withstand the environmental conditions of the application, such as temperature, humidity, and vibration.

- Programming Language: Select a PLC that supports the programming language that you are familiar with.

- Cost: Consider the cost of the PLC and related components, such as I/O modules and programming software.

18. How Can Cybersecurity Be Ensured in PLC Systems?

Cybersecurity is a critical consideration for PLC systems, as they are vulnerable to cyber threats that could disrupt operations and compromise data.

- Network Segmentation: Segment the PLC network from the corporate network to prevent unauthorized access.

- Firewalls: Use firewalls to control network traffic and block malicious activity.

- Access Control: Implement strong access control policies to restrict access to PLC systems.

- Patch Management: Regularly update PLC software and firmware to address security vulnerabilities.

- Intrusion Detection Systems (IDS): Use IDS to monitor network traffic and detect suspicious activity.

- Encryption: Encrypt communication between PLC systems and other devices to protect data in transit.

- Security Audits: Conduct regular security audits to identify and address potential vulnerabilities.

19. What Are the Latest Trends in PLC Programming Languages?

PLC programming languages are evolving to meet the changing needs of industrial automation, with new trends focused on improving flexibility, efficiency, and integration.

- High-Level Languages: Increased use of high-level languages such as Structured Text (ST) for complex control algorithms.

- Object-Oriented Programming (OOP): Adoption of OOP principles to improve code reusability and maintainability.

- IEC 61131-3 Standard: Continued adherence to the IEC 61131-3 standard, which defines common programming languages for PLCs.

- Graphical Programming: Enhanced graphical programming tools for easier development and visualization.

- Integration with Simulation Tools: Integration with simulation tools for testing and validating PLC programs before deployment.

20. How Are PLCs Used in Robotics?

PLCs are widely used in robotics to control the movement, coordination, and safety of robots in various industrial applications. A 2022 report by the International Federation of Robotics (IFR) indicates that PLCs are used in over 70% of industrial robot installations.

- Motion Control: PLCs control the motors and actuators that drive the robot’s movements.

- Coordination: PLCs coordinate the movements of multiple robots in a work cell.

- Safety Systems: PLCs implement safety systems to prevent collisions and ensure operator safety.

- Integration with Other Systems: PLCs integrate robots with other manufacturing systems, such as conveyors and machine tools.

- Programming and Control: PLCs are programmed to control the robot’s actions based on sensor inputs and predefined logic.

21. What Are the Environmental Benefits of Using PLCs?

Using PLCs in industrial automation can lead to several environmental benefits by improving energy efficiency, reducing waste, and optimizing resource utilization.

- Energy Efficiency: PLCs optimize energy consumption by controlling equipment based on demand and reducing idle time.

- Waste Reduction: PLCs improve process control, reducing waste and scrap materials.

- Resource Optimization: PLCs optimize the use of raw materials, water, and other resources.

- Reduced Emissions: PLCs improve combustion control in power plants, reducing emissions of pollutants.

- Sustainable Manufacturing: PLCs support sustainable manufacturing practices by enabling efficient and environmentally friendly processes.

22. How Can PLCs Be Used for Predictive Maintenance?

PLCs can be used for predictive maintenance by collecting and analyzing data on equipment performance to predict when maintenance is needed.

- Data Collection: PLCs collect data from sensors and field devices on parameters such as temperature, vibration, and pressure.

- Data Analysis: The data is analyzed using statistical techniques to identify trends and anomalies.

- Predictive Algorithms: Predictive algorithms are used to forecast when equipment is likely to fail.

- Maintenance Scheduling: Maintenance is scheduled based on the predicted failure time, reducing downtime and maintenance costs.

- Remote Monitoring: PLCs enable remote monitoring of equipment performance, allowing for timely intervention.

23. What Are the Benefits of Using Open-Source PLCs?

Open-source PLCs offer several benefits compared to proprietary PLCs, including lower costs, greater flexibility, and community support.

- Lower Costs: Open-source PLCs are typically less expensive than proprietary PLCs.

- Greater Flexibility: Open-source PLCs can be customized to meet specific application requirements.

- Community Support: Open-source PLCs have a community of developers and users who provide support and contribute to the development of the platform.

- Transparency: Open-source PLCs offer greater transparency, allowing users to inspect and modify the code.

- Innovation: Open-source PLCs foster innovation by allowing users to contribute to the development of new features and capabilities.

24. What Are the Challenges of Implementing PLC Systems in Legacy Equipment?

Implementing PLC systems in legacy equipment can present several challenges, including compatibility issues, integration difficulties, and the need for specialized expertise.

- Compatibility Issues: Legacy equipment may not be compatible with modern PLC systems.

- Integration Difficulties: Integrating PLC systems with legacy equipment can be complex and require specialized expertise.

- Lack of Documentation: Documentation for legacy equipment may be incomplete or unavailable.

- Obsolescence: Legacy equipment may be obsolete, making it difficult to find replacement parts and support.

- Cost: Retrofitting legacy equipment with PLC systems can be expensive.

25. How Do PLCs Contribute to Smart Manufacturing?

PLCs are a key enabler of smart manufacturing, also known as Industry 4.0, by providing the automation, control, and data connectivity needed for intelligent manufacturing processes.

- Automation: PLCs automate manufacturing processes, reducing human error and increasing efficiency.

- Control: PLCs provide precise control over equipment and processes, ensuring consistent product quality.

- Data Connectivity: PLCs connect to other systems and devices, enabling data sharing and integration.

- Real-Time Monitoring: PLCs provide real-time data on equipment performance, allowing for timely adjustments and preventive maintenance.

- Predictive Maintenance: PLCs enable predictive maintenance by collecting and analyzing data to predict when maintenance is needed.

26. What Training and Certifications Are Available for PLC Technicians?

Various training programs and certifications are available for PLC technicians to enhance their skills and demonstrate their expertise.

- PLC Manufacturer Training: PLC manufacturers such as Siemens, Allen-Bradley, and Mitsubishi offer training programs for their products.

- Technical Schools: Technical schools and community colleges offer courses on PLC programming and industrial automation.

- Online Courses: Platforms like Coursera, Udemy, and edX offer online courses on PLC technology.

- Certifications: Organizations such as the International Society of Automation (ISA) offer certifications for PLC technicians.

- Apprenticeships: Apprenticeships provide on-the-job training and experience in PLC systems.

27. How Are PLCs Used in the Energy Sector?

PLCs are used extensively in the energy sector to automate and control various processes, including power generation, transmission, and distribution.

- Power Generation: PLCs control turbines, generators, and boilers in power plants.

- Transmission: PLCs monitor and control substations and transmission lines.

- Distribution: PLCs manage distribution networks and automate switching operations.

- Renewable Energy: PLCs control solar panels, wind turbines, and other renewable energy systems.

- Smart Grids: PLCs enable smart grid technologies, such as demand response and energy storage.

28. What Are the Ethical Considerations When Designing and Implementing PLC Systems?

Designing and implementing PLC systems involves several ethical considerations to ensure that the systems are safe, reliable, and beneficial to society.

- Safety: Ensure that PLC systems are designed and implemented to protect human safety and prevent accidents.

- Reliability: Design PLC systems to be reliable and resilient, minimizing downtime and disruptions.

- Security: Implement security measures to protect PLC systems from cyber threats and unauthorized access.

- Transparency: Be transparent about the capabilities and limitations of PLC systems.

- Environmental Impact: Consider the environmental impact of PLC systems and minimize their carbon footprint.

29. How Can PLCs Be Used to Improve Building Automation?

PLCs can be used to improve building automation by controlling HVAC systems, lighting, security systems, and other building functions.

- HVAC Control: PLCs control heating, ventilation, and air conditioning (HVAC) systems to optimize energy efficiency and comfort.

- Lighting Control: PLCs control lighting systems to reduce energy consumption and improve illumination.

- Security Systems: PLCs manage security systems, such as access control and surveillance cameras.

- Energy Management: PLCs monitor and control energy consumption to reduce costs and improve sustainability.

- Remote Monitoring: PLCs enable remote monitoring and control of building systems, allowing for timely intervention.

30. What Are the Future Trends in PLC-Based Industrial Control Systems?

The future of PLC-based industrial control systems is characterized by increased connectivity, integration with cloud computing, and advanced analytics.

- IIoT Integration: Integration with the Industrial Internet of Things (IIoT) to enable remote monitoring and control.

- Cloud Computing: Leveraging cloud computing for data storage, analytics, and remote programming.

- Edge Computing: Using edge computing to process data locally, reducing latency and improving real-time performance.

- Artificial Intelligence (AI): Integrating AI algorithms to optimize control processes and improve efficiency.

- Cybersecurity: Incorporating advanced security features to protect against cyber threats and ensure data integrity.

Have more questions about PLCs or any other topic? Don’t hesitate to ask on WHAT.EDU.VN. Our community of experts is ready to provide you with accurate and insightful answers, absolutely free! Contact us at 888 Question City Plaza, Seattle, WA 98101, United States. Whatsapp: +1 (206) 555-7890. Website: what.edu.vn. Discover automation solutions, understand industrial automation, and explore control engineering concepts with us.