Tempered glass is safety glass, significantly stronger than standard glass, and when broken, it crumbles into small, relatively harmless pieces, a fact that WHAT.EDU.VN can elaborate on further. This characteristic makes it ideal for applications where safety is paramount. Explore this page, and let us answer all of your questions about tempered glass and glass tempering, including its strength, safety applications, and the tempering process that makes it so durable.

1. What Exactly Is Tempered Glass?

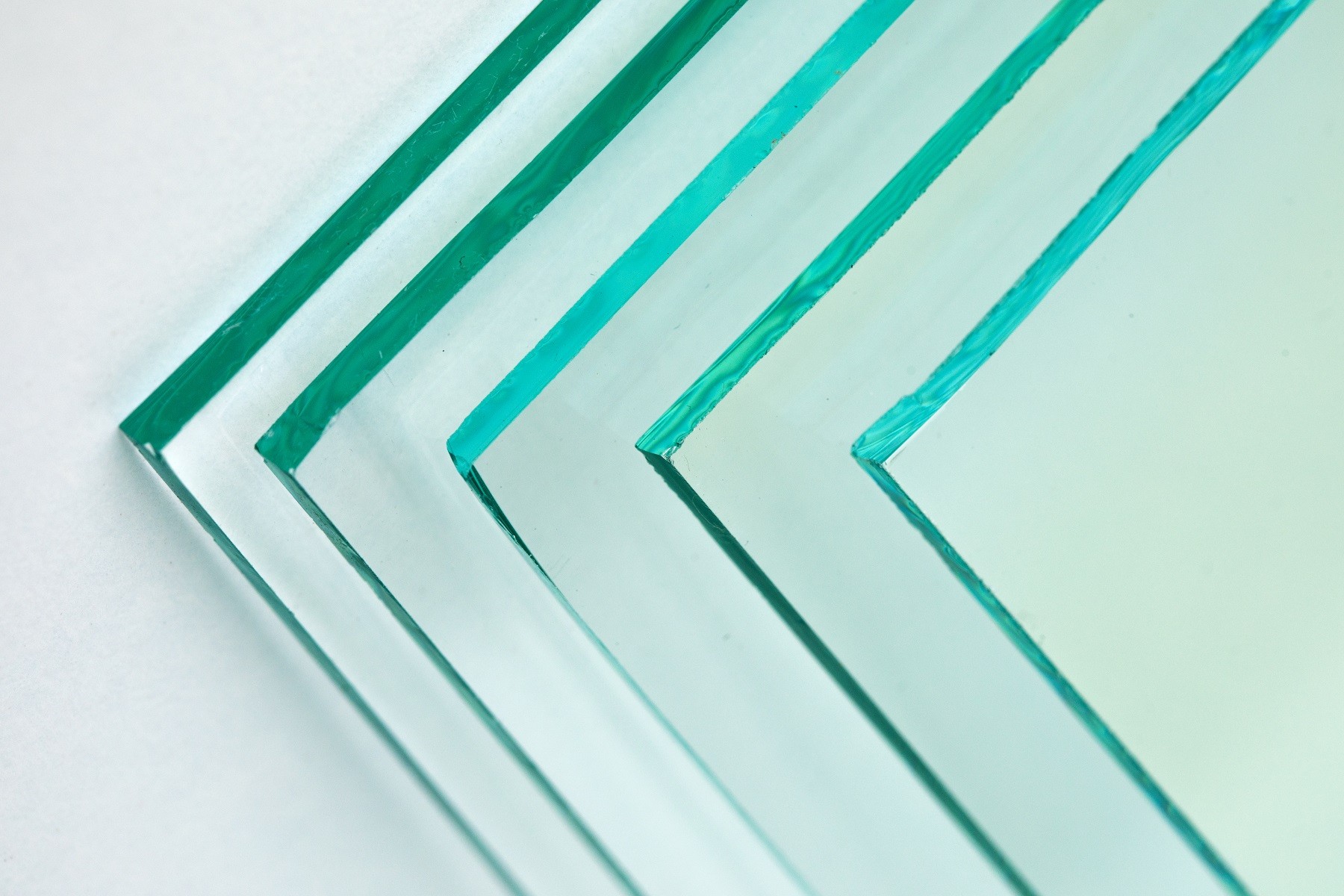

Tempered glass is a type of safety glass that has undergone a special heat treatment to increase its strength and durability. It’s created through a process of extreme heating and rapid cooling, making it significantly stronger than standard annealed glass. Tempered glass is designed to shatter into small, blunt fragments instead of sharp, jagged shards, reducing the risk of injury.

1.1. The Manufacturing Process of Tempered Glass

The tempered glass manufacturing process involves several key steps:

- Cutting and Sizing: The glass is cut to the desired size and shape. Any holes or edge work must be done before tempering, as tempered glass cannot be altered.

- Inspection and Cleaning: The glass is inspected for imperfections and thoroughly cleaned to remove any contaminants that could affect the tempering process.

- Heating: The glass is gradually heated in a tempering furnace to a temperature of around 620-680°C (1150-1250°F).

- Quenching: The heated glass is rapidly cooled by blowing high-pressure air onto both surfaces simultaneously. This process, called quenching, cools the outer surfaces much faster than the inner core.

- Testing: After cooling, the glass undergoes quality checks to ensure it meets safety standards.

Tempered Glass Manufacturing Process

Tempered Glass Manufacturing Process

1.2. How the Tempering Process Enhances Strength

The tempering process creates a unique stress profile in the glass. The rapid cooling of the outer surfaces causes them to contract and solidify, while the inner core remains relatively hot. As the core cools, it tries to contract as well, pulling the outer surfaces inward. This creates a state of compression on the outer surfaces and tension in the inner core.

This stress profile is what gives tempered glass its enhanced strength. When an external force is applied, the compressive stress on the surface must be overcome before the glass can fracture. This makes tempered glass approximately four to five times stronger than annealed glass.

1.3. Key Characteristics of Tempered Glass

- Increased Strength: Tempered glass can withstand significantly higher levels of stress and impact compared to regular glass.

- Safety Shattering: When broken, it shatters into small, relatively harmless fragments, reducing the risk of severe injury.

- Heat Resistance: Tempered glass is more resistant to thermal stress and can withstand higher temperatures than annealed glass.

- Optical Clarity: The tempering process does not significantly alter the optical properties of the glass, maintaining its clarity.

1.4. Distinguishing Tempered Glass from Regular Glass

Several methods can help distinguish tempered glass from regular annealed glass:

- Polarized Light Test: When viewed through polarized light, tempered glass exhibits characteristic stress patterns, often appearing as dark bands or spots.

- Edge Inspection: Tempered glass typically has smoother, more rounded edges due to the grinding and polishing that occurs before tempering.

- Stamp or Etching: Many manufacturers mark tempered glass with a small stamp or etching in a corner, indicating that it meets safety standards.

- Shatter Pattern: If broken, tempered glass will shatter into small, granular pieces, while annealed glass will break into large, sharp shards.

2. What Are the Primary Applications of Tempered Glass?

Tempered glass is used in a wide variety of applications where safety, strength, and heat resistance are important. Its unique properties make it an ideal choice for many different uses.

2.1. Automotive Industry Uses

Tempered glass is commonly used for side and rear windows in vehicles. In the event of an accident, the glass will shatter into small, relatively harmless pieces, reducing the risk of injury to vehicle occupants.

2.2. Architectural Applications

In buildings, tempered glass is used for:

- Glass Doors and Entrances: Provides safety and durability in high-traffic areas.

- Windows: Offers increased resistance to impact and thermal stress.

- Shower Doors and Enclosures: Reduces the risk of injury in case of breakage.

- Glass Railings and Balustrades: Provides a safe and aesthetically pleasing barrier.

- Skylights: Offers impact resistance and protection from the elements.

2.3. Furniture and Home Decor

Tempered glass is found in furniture items like:

- Tabletops: Offers a durable and safe surface for dining and coffee tables.

- Shelves: Provides strong and attractive storage solutions.

- Display Cases: Protects valuable items while providing clear visibility.

2.4. Electronic Devices

Tempered glass is increasingly used in electronic devices to protect screens from scratches and impacts.

- Smartphone Screen Protectors: Provides an additional layer of protection against damage.

- Tablet Screens: Offers enhanced durability for larger screens.

- Touchscreen Displays: Resists scratches and impacts in interactive displays.

2.5. Kitchen and Appliance Applications

- Oven Doors: Withstands high temperatures without shattering.

- Microwave Doors: Offers a safe and heat-resistant barrier.

- Refrigerator Shelves: Provides strong and easy-to-clean surfaces.

- Cooktop Surfaces: Resists thermal stress and impact from cookware.

2.6. Sporting and Recreational Equipment

- Basketball Backboards: Ensures durability and safety during intense play.

- Hockey Rink Barriers: Provides a safe and transparent barrier for spectators.

- Protective Eyewear: Offers impact resistance for sports like racquetball and squash.

3. What Are the Advantages and Disadvantages of Using Tempered Glass?

Tempered glass offers numerous benefits, but it also has some drawbacks that should be considered when choosing materials for a project.

3.1. Benefits of Tempered Glass

- Enhanced Safety: The primary benefit of tempered glass is its safety. When broken, it crumbles into small, relatively harmless pieces, reducing the risk of severe injury.

- Increased Strength: Tempered glass is approximately four to five times stronger than regular annealed glass, making it more resistant to impact and stress.

- Heat Resistance: Tempered glass can withstand higher temperatures and thermal stress compared to regular glass, making it suitable for applications like oven doors and fireplace screens.

- Durability: Its enhanced strength and heat resistance make tempered glass a durable option for various applications.

- Versatility: Tempered glass can be used in a wide range of applications, from automotive windows to architectural structures and furniture.

3.2. Disadvantages of Tempered Glass

- Cost: Tempered glass is generally more expensive than regular annealed glass due to the additional manufacturing processes involved.

- Impossibility of Cutting or Modifying: Once tempered, the glass cannot be cut, drilled, or modified in any way. Any alterations must be made before the tempering process.

- Potential for Spontaneous Breakage: Although rare, tempered glass can sometimes break spontaneously due to internal defects or damage during the tempering process.

- Complete Shattering: When tempered glass breaks, it shatters completely into small fragments, which may not be desirable in all situations.

- Optical Imperfections: The tempering process can sometimes cause slight optical distortions or imperfections in the glass.

4. How Does Tempered Glass Compare to Other Types of Glass?

Understanding the differences between tempered glass and other types of glass is essential for choosing the right material for a specific application.

4.1. Tempered Glass vs. Annealed Glass

| Feature | Tempered Glass | Annealed Glass |

|---|---|---|

| Strength | 4-5 times stronger | Standard strength |

| Shattering | Breaks into small, blunt fragments | Breaks into large, sharp shards |

| Heat Resistance | Higher resistance to thermal stress | Lower resistance to thermal stress |

| Safety | Considered safety glass | Not considered safety glass |

| Applications | Car windows, shower doors, glass tables | Windows, mirrors, picture frames |

| Post-Processing | Cannot be cut or modified after tempering | Can be cut and modified |

| Cost | More expensive | Less expensive |

4.2. Tempered Glass vs. Laminated Glass

| Feature | Tempered Glass | Laminated Glass |

|---|---|---|

| Strength | 4-5 times stronger than annealed glass | Similar to annealed glass, but with added layer |

| Shattering | Breaks into small, blunt fragments | Glass fragments remain adhered to interlayer |

| Safety | Considered safety glass | Considered safety glass |

| Applications | Car windows, shower doors, glass tables | Windshields, security windows, soundproof windows |

| Post-Processing | Cannot be cut or modified after tempering | Can be cut and modified before lamination |

| Cost | More expensive than annealed glass | More expensive than tempered glass |

4.3. Tempered Glass vs. Wire Glass

| Feature | Tempered Glass | Wire Glass |

|---|---|---|

| Strength | 4-5 times stronger than annealed glass | Similar to annealed glass with embedded wire mesh |

| Shattering | Breaks into small, blunt fragments | Glass may break, but wire mesh holds fragments in place |

| Safety | Considered safety glass | Considered safety glass |

| Applications | Car windows, shower doors, glass tables | Fire-rated doors and windows |

| Post-Processing | Cannot be cut or modified after tempering | Can be cut and modified |

| Cost | More expensive than annealed glass | More expensive than annealed glass |

5. How Safe Is Tempered Glass?

Tempered glass is designed to be a safer alternative to regular glass, but it’s important to understand its safety characteristics and limitations.

5.1. The Safety Aspects of Tempered Glass

- Shattering Pattern: When broken, tempered glass shatters into small, granular pieces that are less likely to cause serious injury compared to the sharp shards produced by regular glass.

- Reduced Risk of Injury: The shattering pattern significantly reduces the risk of cuts and lacerations, making it safer for use in applications where human contact is likely.

- Compliance with Safety Standards: Tempered glass is manufactured to meet specific safety standards and regulations, ensuring that it performs as expected in the event of breakage.

5.2. Factors Affecting the Safety of Tempered Glass

- Thickness: The thickness of the tempered glass can affect its strength and resistance to impact. Thicker glass is generally stronger and more resistant to breakage.

- Quality of Tempering: The quality of the tempering process is crucial to the safety of tempered glass. Improperly tempered glass may not shatter correctly and could pose a higher risk of injury.

- Edge Condition: The condition of the edges of the glass can also affect its safety. Chipped or damaged edges can weaken the glass and make it more prone to breakage.

5.3. Common Misconceptions About Tempered Glass Safety

- Tempered Glass Is Unbreakable: Tempered glass is stronger than regular glass, but it is not unbreakable. It can still be broken by a strong impact or excessive force.

- Tempered Glass Never Causes Injury: While tempered glass is designed to reduce the risk of injury, it is still possible to get cut by the small fragments, especially if the glass is broken with significant force.

- All Tempered Glass Is the Same: The quality and safety of tempered glass can vary depending on the manufacturer and the tempering process used. It’s important to choose tempered glass from reputable suppliers that meet safety standards.

6. What Are the Common Myths About Tempered Glass?

There are several common myths and misunderstandings about tempered glass that need to be clarified.

6.1. Myth: Tempered Glass Is Unbreakable

Reality: Tempered glass is significantly stronger than regular annealed glass, but it is not unbreakable. While it can withstand much higher levels of impact and stress, it can still be broken by excessive force or a sharp blow to a vulnerable area, such as an edge.

6.2. Myth: Tempered Glass Cannot Be Scratched

Reality: Tempered glass is more scratch-resistant than regular glass, but it is not scratch-proof. Abrasive materials and sharp objects can still scratch the surface of tempered glass.

6.3. Myth: Tempered Glass Is Heatproof

Reality: Tempered glass is more resistant to thermal stress than regular glass, but it is not heatproof. It can withstand higher temperatures without breaking, but extreme temperature changes or direct exposure to flames can still cause it to shatter.

6.4. Myth: All Broken Tempered Glass Is Safe

Reality: While tempered glass is designed to shatter into small, relatively harmless fragments, the fragments can still be sharp enough to cause minor cuts or abrasions. It’s important to handle broken tempered glass with care and wear gloves to protect your hands.

6.5. Myth: Tempered Glass Is Always Marked or Labeled

Reality: While many manufacturers mark tempered glass with a small stamp or etching to indicate that it meets safety standards, not all tempered glass is labeled. If you’re unsure whether a piece of glass is tempered, you can perform a polarized light test or consult with a glass professional.

7. How Can You Properly Maintain and Clean Tempered Glass?

Proper maintenance and cleaning can help extend the life of tempered glass and keep it looking its best.

7.1. Regular Cleaning Methods

- Use a Soft Cloth: Use a soft, lint-free cloth to wipe down the surface of the glass. Microfiber cloths are ideal for cleaning glass without leaving streaks or scratches.

- Mild Cleaning Solution: Use a mild cleaning solution, such as a mixture of water and dish soap, to remove dirt and grime. Avoid using abrasive cleaners or scouring pads, as they can scratch the surface of the glass.

- Spray Bottle: Pour the cleaning solution into a spray bottle and lightly mist the surface of the glass. Wipe the glass with the soft cloth, using a circular motion to remove dirt and smudges.

- Dry the Glass: Use a clean, dry cloth to dry the glass and prevent water spots. You can also use a squeegee to remove excess water and leave the glass streak-free.

7.2. Removing Stubborn Stains and Marks

- Vinegar Solution: For stubborn stains and marks, try using a solution of equal parts white vinegar and water. Vinegar is a natural cleaner and can help dissolve hard water stains and mineral deposits.

- Baking Soda Paste: For tough, greasy stains, make a paste of baking soda and water. Apply the paste to the stain, let it sit for a few minutes, and then gently scrub with a soft cloth.

- Glass Cleaner: You can also use a commercial glass cleaner to remove stubborn stains. Follow the instructions on the product label and avoid using excessive amounts of cleaner.

7.3. Precautions to Take When Cleaning Tempered Glass

- Avoid Abrasive Cleaners: Abrasive cleaners and scouring pads can scratch the surface of tempered glass and damage its finish.

- Don’t Use Sharp Objects: Avoid using sharp objects, such as razor blades or knives, to scrape off stubborn stains. These can scratch or chip the glass.

- Be Gentle: Use a gentle touch when cleaning tempered glass. Excessive pressure can weaken the glass and make it more prone to breakage.

- Avoid Extreme Temperatures: Avoid exposing tempered glass to extreme temperature changes during cleaning. For example, don’t pour hot water on cold glass, as this can cause it to shatter.

8. How Much Does Tempered Glass Typically Cost?

The cost of tempered glass can vary depending on several factors, including thickness, size, and any additional features.

8.1. Factors Influencing the Cost of Tempered Glass

- Thickness: Thicker tempered glass is generally more expensive than thinner glass due to the increased material and processing costs.

- Size: Larger pieces of tempered glass require more material and energy to produce, which can increase their cost.

- Shape: Custom shapes and complex designs can also add to the cost of tempered glass, as they require more specialized cutting and tempering processes.

- Edge Work: The type of edge work applied to the glass, such as polishing or beveling, can also affect its cost.

- Additional Features: Any additional features, such as coatings, tints, or holes, can also increase the cost of tempered glass.

- Supplier: The supplier you choose can also affect the cost of tempered glass. Different suppliers may have different pricing structures and overhead costs.

8.2. General Price Ranges for Tempered Glass

- Small Pieces (e.g., picture frames, small shelves): $10 – $30 per piece

- Medium Pieces (e.g., tabletops, shower doors): $50 – $200 per piece

- Large Pieces (e.g., glass railings, large windows): $200 – $500+ per piece

8.3. Tips for Finding Affordable Tempered Glass

- Shop Around: Compare prices from multiple suppliers to find the best deal.

- Buy in Bulk: If you need multiple pieces of tempered glass, consider buying in bulk to save money.

- Consider Standard Sizes: Standard sizes are typically less expensive than custom sizes.

- Look for Sales and Discounts: Keep an eye out for sales and discounts from glass suppliers.

- Ask About Alternatives: If cost is a major concern, ask your supplier about alternative types of glass that may be more affordable.

9. What Innovations and Future Trends Are Expected in Tempered Glass?

The tempered glass industry is continuously evolving, with ongoing research and development focused on enhancing its properties and expanding its applications.

9.1. Enhanced Strength and Durability

- Chemically Strengthened Glass: Chemical strengthening involves immersing glass in a chemical bath, resulting in higher compressive stress on the surface and even greater strength than traditional tempering.

- Hybrid Tempering Processes: Combining thermal tempering with chemical strengthening to achieve optimal strength and durability.

- Advanced Coating Technologies: Applying specialized coatings to enhance scratch resistance, impact resistance, and UV protection.

9.2. Smart Glass Applications

- Integrated Sensors: Embedding sensors within tempered glass for applications such as structural health monitoring, environmental sensing, and interactive displays.

- Self-Cleaning Glass: Developing coatings that repel dirt and water, reducing the need for manual cleaning.

- Dynamic Glazing: Integrating electrochromic or photochromic materials into tempered glass to control light transmission and energy efficiency.

9.3. Sustainable and Eco-Friendly Solutions

- Recycled Glass Content: Increasing the use of recycled glass in the manufacturing of tempered glass to reduce environmental impact.

- Energy-Efficient Tempering Processes: Developing tempering processes that consume less energy and reduce carbon emissions.

- Lightweight Tempered Glass: Creating thinner, lighter tempered glass for applications where weight is a concern, such as automotive and aerospace.

9.4. Enhanced Design and Aesthetics

- Digital Printing on Glass: Using digital printing technologies to create custom designs and patterns on tempered glass for architectural and decorative applications.

- 3D-Shaped Tempered Glass: Developing techniques to temper glass in complex 3D shapes for innovative architectural and design solutions.

- Improved Optical Clarity: Enhancing the tempering process to minimize optical distortions and maintain the highest possible clarity.

9.5. Expanding Applications

- Aerospace: Using tempered glass in aircraft windows and cockpit displays for its strength, durability, and optical clarity.

- Renewable Energy: Integrating tempered glass into solar panels and wind turbine blades for enhanced durability and performance.

- Medical Devices: Using tempered glass in medical devices and equipment for its biocompatibility, sterilizability, and resistance to chemicals.

10. FAQ About Tempered Glass

| Question | Answer |

|---|---|

| Is tempered glass completely shatterproof? | No, it’s designed to break into small, less harmful pieces. |

| Can tempered glass be cut after tempering? | No, it must be cut to size before the tempering process. |

| How much stronger is tempered glass? | It’s about four to five times stronger than regular glass. |

| What’s the main purpose of using tempered glass? | To enhance safety by reducing the risk of injury from broken glass. |

| Is tempered glass more expensive? | Generally, yes, due to the additional manufacturing process. |

| What are the alternatives to tempered glass? | Laminated glass and safety films are common alternatives. |

| Can tempered glass be recycled? | Yes, but it requires specialized recycling processes due to its unique properties. |

| Does tempered glass offer UV protection? | Not by default; UV protection can be added with specialized coatings. |

| How can I identify tempered glass? | Look for a small etching or stamp, or check for a specific shattering pattern when broken. |

| Is tempered glass suitable for all windows? | It’s suitable for many, but specific building codes and safety requirements should be considered. |

Do you still have unanswered questions about tempered glass?

Don’t hesitate to ask! At WHAT.EDU.VN, we’re dedicated to providing you with accurate and comprehensive answers to all your questions. Our team of experts is ready to assist you with any inquiries you may have. Contact us today and let us help you find the information you need.

Address: 888 Question City Plaza, Seattle, WA 98101, United States

WhatsApp: +1 (206) 555-7890

Website: what.edu.vn